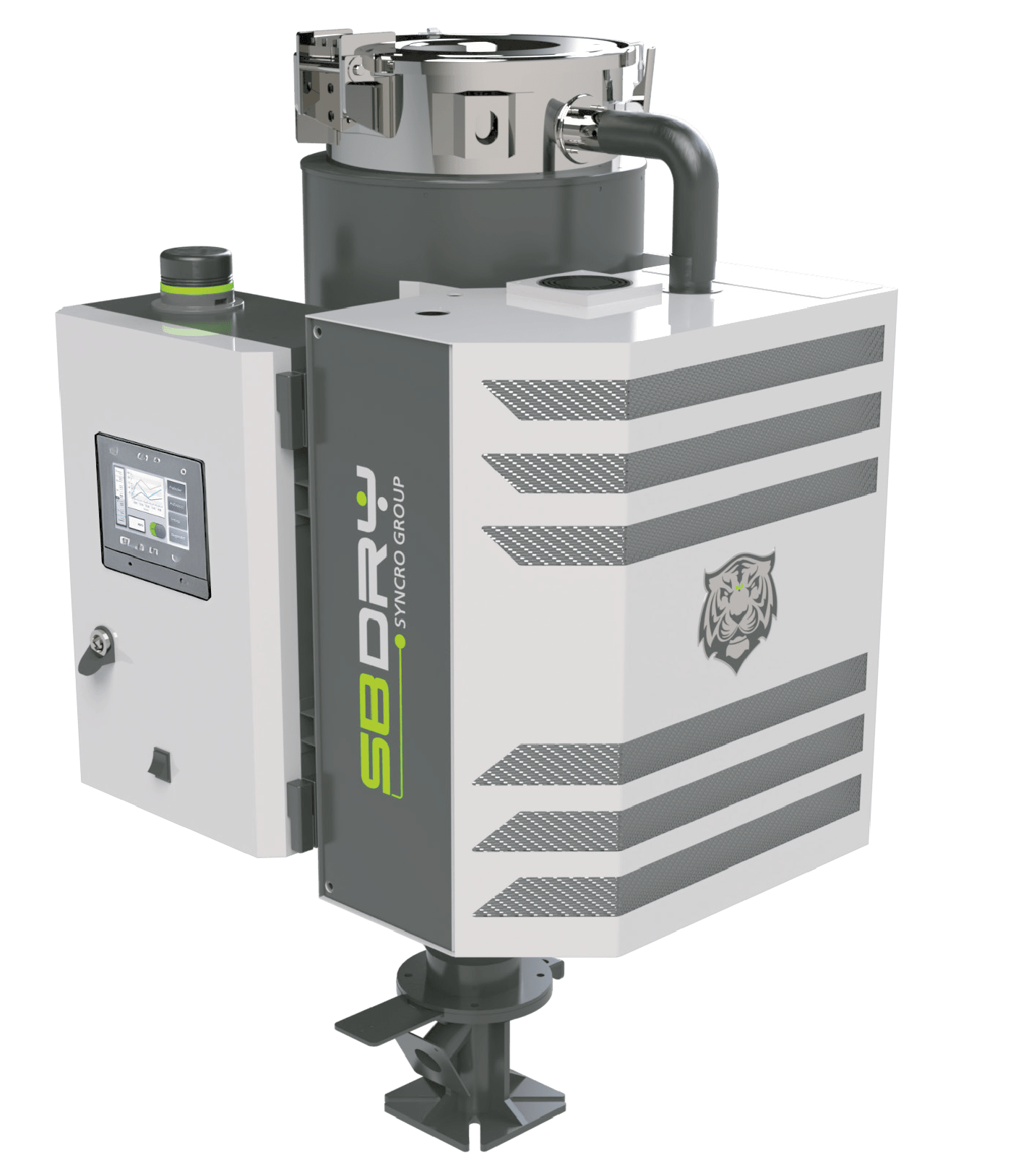

- COMPACT AND EFFICIENT - The small number of movable parts allows the system to have a footprint very compact. Moreover all the parts are also easily accessible for a fast and safe cleaning maintenance.

- HIGH PERFORMANCE - Possibility to chose the Dew point between 0 and -40°C. PID integrated control for an accuracy in heating of ±1°C. The absence of cooling, necessary only for few kinds of materials, allow also a supplementary energy reduction.

- REDUCTION OF POSSIBILITY OF FAULT - Because of smaller number of movable parts the Honey Comb Rotor dehumidifier has a lower “Index of Fault”, and consequentiality a reduction of possible stops of the equipment, with an higher shelf life.

- FLEXIBILITY - Adjustment of Dew Point is the key-point, because it allows machine to work according to customer’s requirements.

- RANGE OF MODELS - Three models with three sizes of hoppers, for a hourly production up to 25 kg/h depending of the material.

- EASYNESS - Designed to be fitted directly above the Transforming Machine or on the dosing stations to treat also additives or masterbatches.

- AUTOMATIC OPTIMIZATION - Adaptive Energy Saving Function (Optional) adjusts automatically drying airflow and process temperature, according to different materials and outputs, and reduces also risk of over-drying.

- OPTIONS - Built-in Dew Point Supplementary Monitor. Energy Drying Management System (Adjustment from 100% down to 40%).

- INDUSTRY 4.0 & IoT - Thanks to HMI control and integrated OPC-UA standard protocol the machine can be easily connected to an ERP MES System running in “Industry 4.0”

syncro-DRY

Material handling solutions

Wheel To Dry • Mini

Honeycomb Rotor Dehumidifier

WHEEL TO DRY is an high performance dehumidifier, very useful for a correct handling of plastic materials. The Wheel to Dry series is a powerful tool for a proper dehumidification of plastic materials and, consequently, an increase in quality of the final products; and an optimisation of energy costs.

Air goes through the desiccant rotor, and releases the moisture extracted from the material in the hopper. The part of the rotor saturated by water is regenerated with hot air; this air, once humid, is then exhausted . Finally, once regenerated, the section of the rotor is cooled down and then ready to absorb again humidity from plastic materials. The possibility to reduce the airflow from 100 to 40% and the Dew Point from -40°C to 0°C is an huge “advantage” in the plastic industry.