- RADIOACTIVITY REGULATIONS - BYtascan is equipped with a Kripton85 active source enclosed in a lead container and fitted with all safety measures; it is now undergoing final verification to be classified as a ‘recognized source’ with residual radiation emitted below the safety level, according to the international standards such as EURATOM.

- PROCESSES - BYtascan can be used for various production processes such as cast/sheet flat die extrusion lines, coating lines, lamination lines, PVC and/or rubber calendering lines.

- LIMITLESS PERFORMANCE - The measurement is not influenced by the color or the transparency of the material.

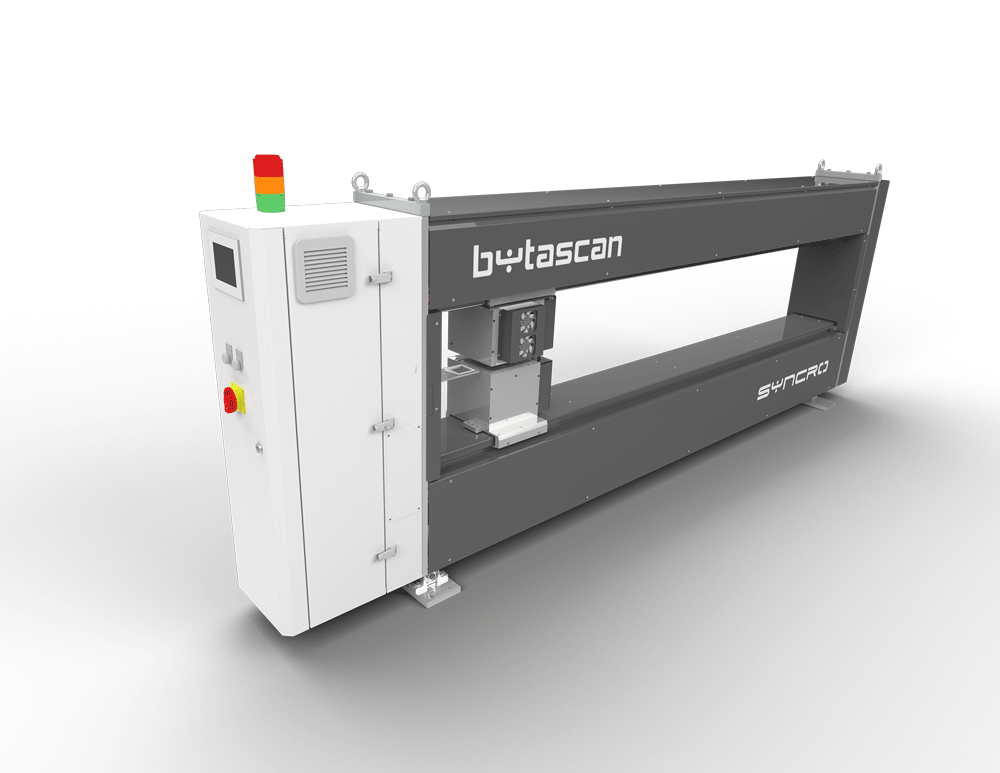

- SCANNER STRUCTURE The solid structure offers excellent resistance to deformations and guarantees perfect measurement stability.

- EASY ACCESS FOR MAINTENANCE The BYtascan is designed to provide quick and easy access for maintenance operations.

- EASY INSTALLATION Installation takes less than 2 hours.

- SYNTROL CONTROL BYtascan is controlled by the SYNTROL supervisory system capable of visualisation, history and adjustments.

- STABLE AND PRECISE The BYtascan measurement is very stable and accurate; repeatability down to 0.1 microns with a maximum drift of 0.15 microns in 12 hours without characterization. The emitter and receiver housings are temperature-controlled, and transfer compensation is balanced via an inductive sensor.

- AUTOMATIC PROFILE CONTROL Available as an option, BYtascan can be interfaced to SYntrolgauge to automatically control the thermal bolts of the flat die, adjust the film or sheet thickness, or change the heaters in automatic air rings heaters in blown film extrusion lines.

- INDUSTRY 4.0 & IoT All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Bytascan

Beta-Ray Gauging System

The BYTASCAN uses the principle of Beta ray transmission through the material to measure its density, weight and thickness usually indicated in g/m2 or μm.

The beta-ray source is fixed inside the transmitter housing, while another housing contains the receiver which is positioned above the transmitter at a known distance (gap). When a material is positioned between the transmitter and receiver, part of the energy emitted by the source is absorbed by the material. The missing part, captured by the receiver, is proportional to the density of the measured film. Once the width and density are known, the system can calculate both weight and thickness.

Processes: