- MICROEX BLOWN is capable to process all the typical materials used for tubular film, from PE and PP to PA, TPU, EVA and Biopolymers, with a thickness ranging from 20 to 100 µm, depending on the processed material.

- Its special screw design allows to use standard commercial pellets and the screw extraction system permits the disassembling of the screw in less than 5 minutes, accelerating the cleaning and maintenance operation.

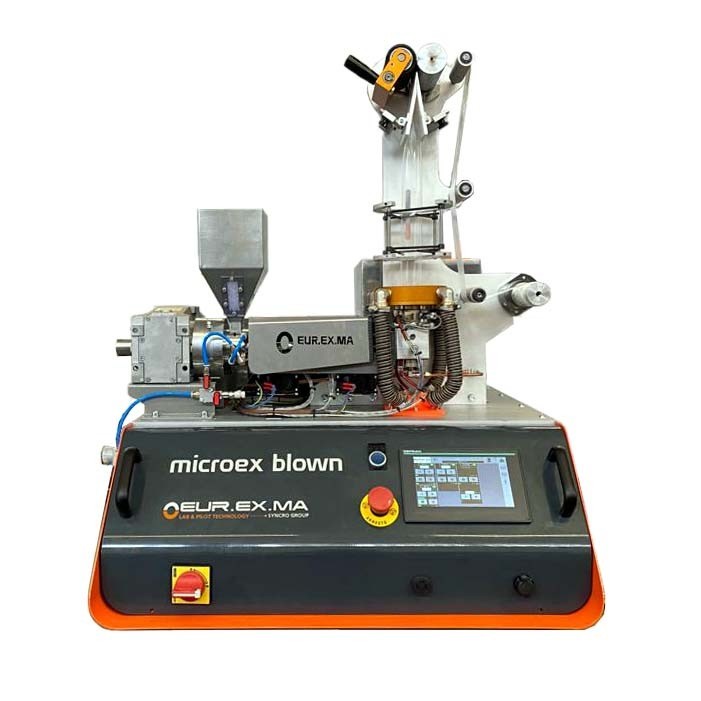

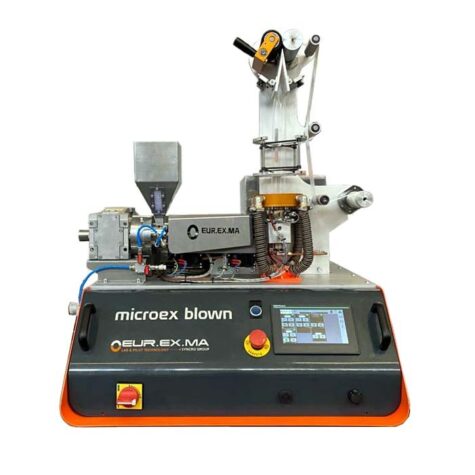

- Composed also of a round die, a dual flow air ring, a calibration basket, a take-off unit and a single shaft winder for the collection of the film reel.

- Plug and play designed, the machine works with single phase industrial plug or standard 240V home plug, with a consumption of less than 3 KW.

- An extremely user friendly control panel allows to save and export process data on external USB memory. The line is easy to interface with an ERP or production management software with integration via industry 4.0.

- MICROEX BLOWN can be equipped with EYES, visual quality inspection system able to detect and categorize all of the commonly known defects, a very smart combination for quality control of recycled polymers.

Microex Blown

Benchtop Blown Film Extrusion Line for Quality Control

MICROEX BLOWN is an extrusion line suitable to create samples of tubular film with the smallest dimensions. Very compact line, equipped with a Microex single screw extruder of 17,5 mm Ø, it is designed for the quality control of recycled materials, color masterbatches, additives and bio-polymers with low consumption and waste.

Processes: