- HARDWARE MODULARITY - Multiple camera configurations are available based on the defect dimensions and process speed. EYES, thanks to the high-resolution cameras and the computing power of its latest generation processors can detect defects down to 25 µm, defects which would be undetectable to the naked eye, this level of accuracy is achievable even with line speeds of up to 1200 m/min.

- HIGH SCANNING SENSITIVITY - In order to identify and classify different kinds of defects, EYES can be equipped with a variety of different back-lighting technologies which all work simultaneously: for instance incident light for working in reflection or diascopic light to work in light transmission.

- SIMPLE AND INTUITIVE INTERFACE - An intuitive HMI control panel helps to improve productivity, giving real-time process visualization with 2D mapping, this allows the operator to quickly view the quantity and density of any defect’s, plus their categorization and position. The system provide process statistical analysis with reporting capability simply from the click of a button.

- WIDE RANGE OF APPLICATIONS - Different frames and hardware configurations are available to inspect any kind of transparent or opaque materials and can be installed on either production lines or converting lines. Examples are: Agicultural film, Technical film for packaging, Barrier film and Battery sheet film

- REPORTING - Detailed inspection reports are generated which follow the recognised Industry Standards allowing for a thorough understanding of the production process, and hence increasing productivity and decreasing waste.

- SIMPLE INSTALLATION - Thanks to EYES’s slim and flexible mounting frames the system has maximum flexibility to be installed within an extrusion line (usually right before the winding section) as well as converting lines, helping guarantee excellent quality control through simple installation.

- INDUSTRY 4.0 AND IoT - The EYES’s software suite is easy to interface with an ERP or production management software system, plus has remote database integration via Industry 4.0. Using standard communication protocols, inspection reports can be digitally transferred to downstream processes after the extrusion process.

Eyeprynt

100% Visual inspection system for plastic film

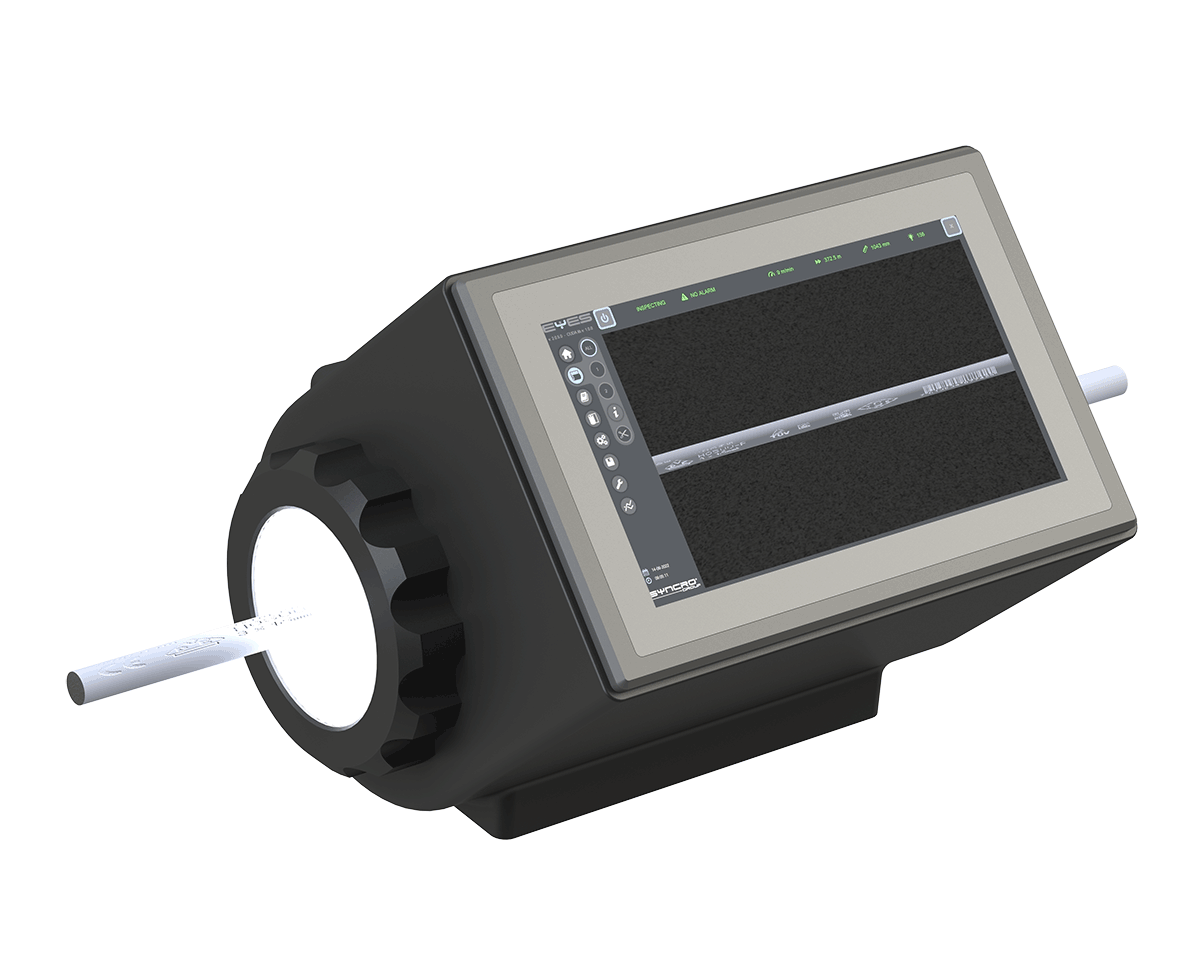

EYEPRYNT allows the print quality of information printed with the inkjet on the cable sheath to be checked. It is installed immediately downstream of the printer and is synchronized with it to determine when to perform the check. The defects detected are typical of dot-matrix printing: Missing or blurred dots and ink leaks in the printing area. The system is available in different configurations for different cable diameters and text dimensions. A version that only allows freeze-framing of the text for operator control is available.