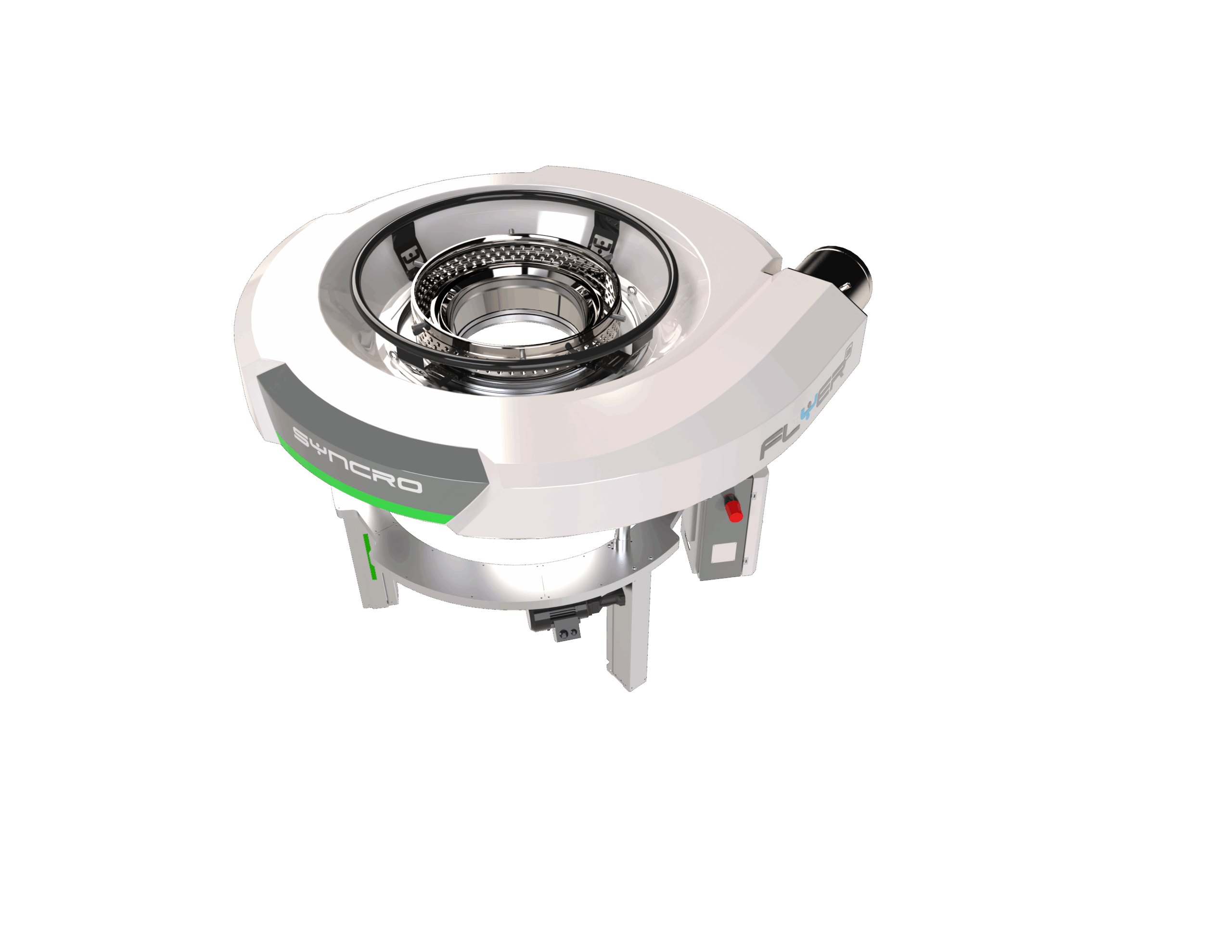

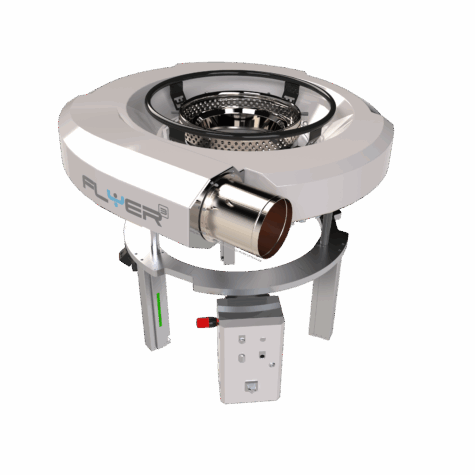

- EASY INSTALLATION FlYer3 can easily replace an existing air ring, improving line performance in areas such as flow rate and profile control with an average ROI (return on investment) of 6-9 months.

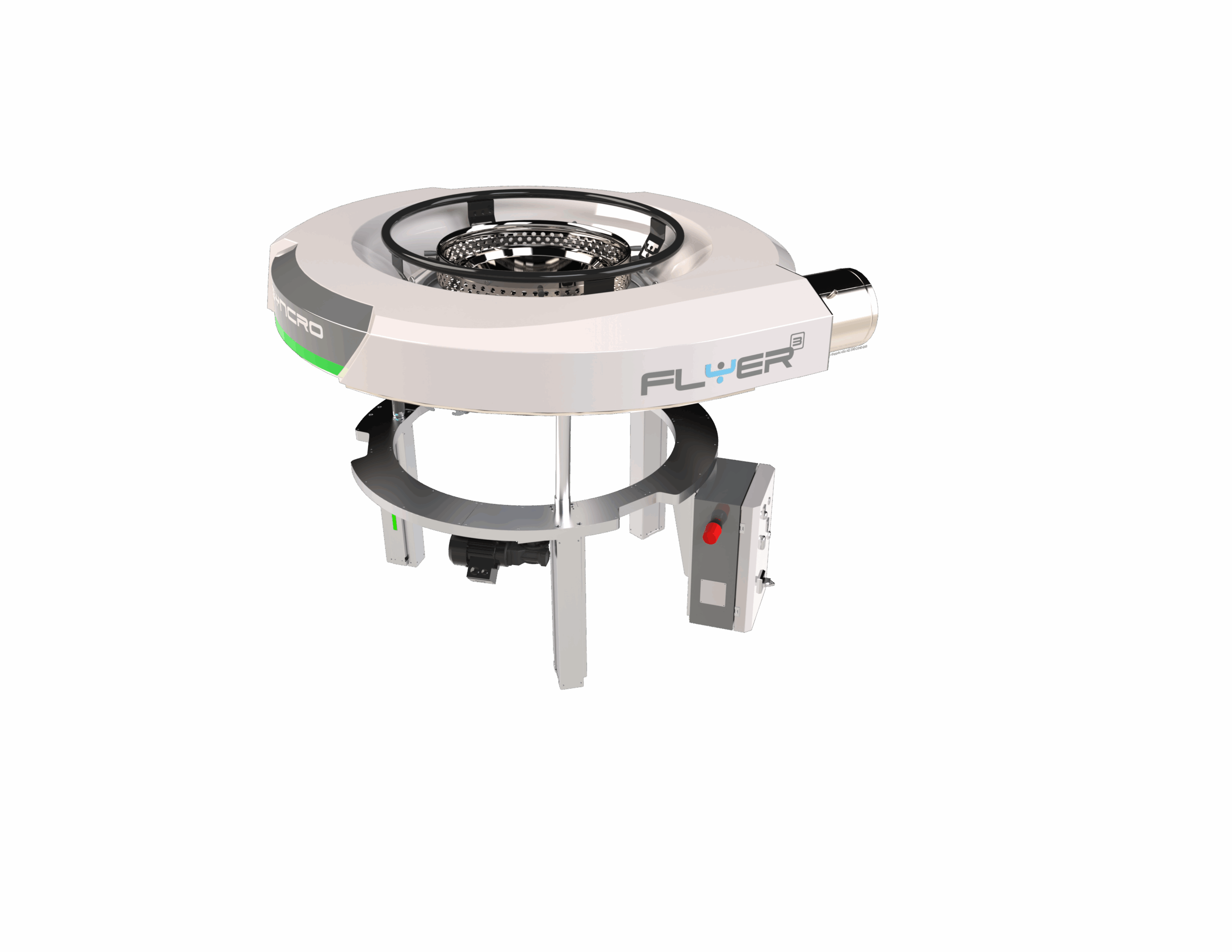

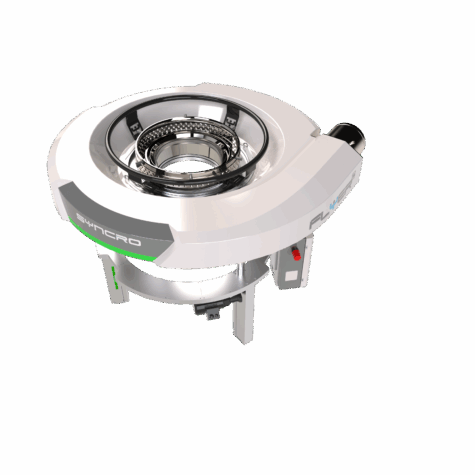

- FIBREGLASS CHAMBER The machine body is natively and fully insulated as it is made of resin and fiber. This ensures high energy efficiency and prevents condensation from forming. The air supply is single-vented tangential. Connecting the ring to the chilled air system is thus simple and the operating space around the machine is improved, facilitating maintenance operations around the head.

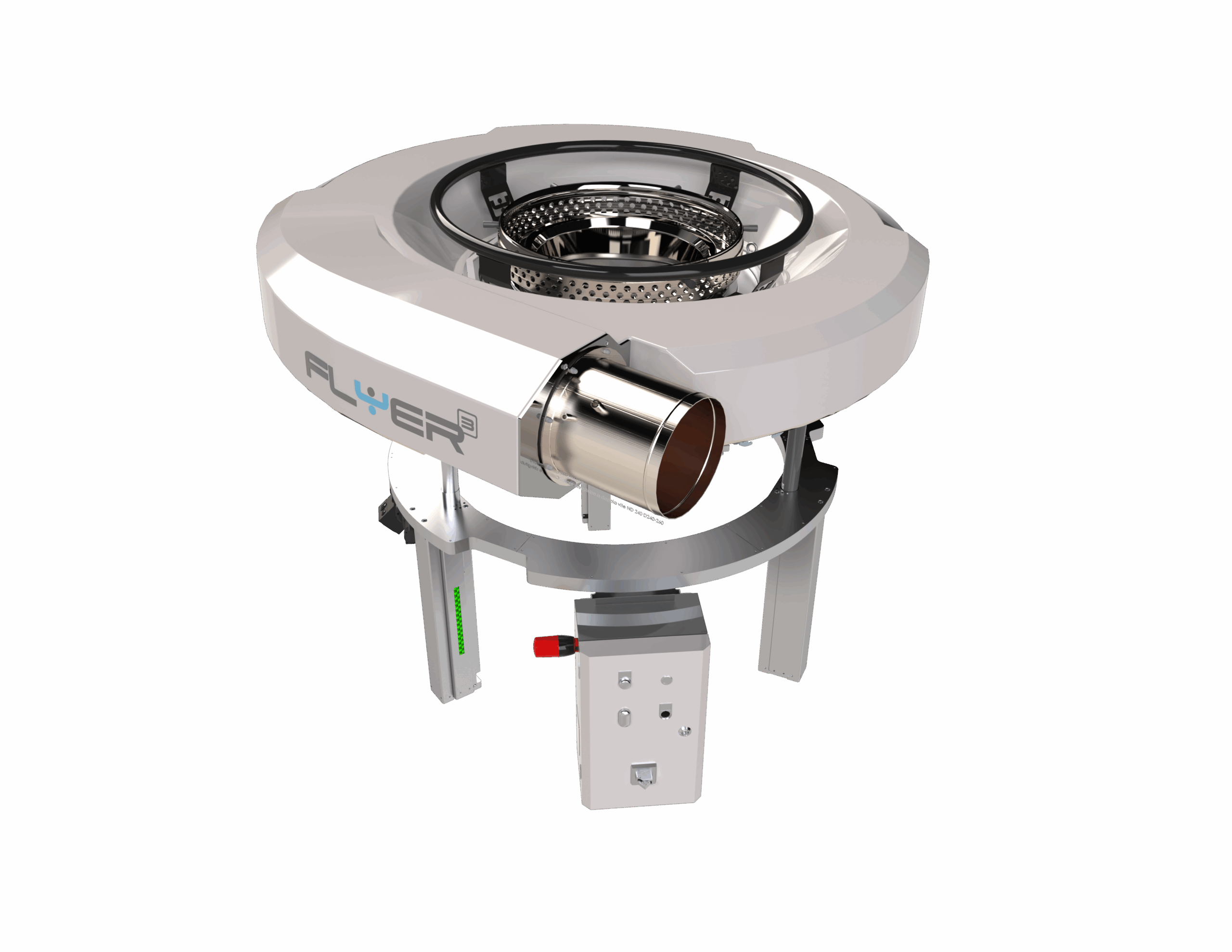

- LIFTING SYSTEM FlYer3 is equipped with a lifting unit controlled by the SYNTROL supervision system, allows the memorisation of the product’s positioning in the recipe, reducing recipe change times to a minimum. The lifting system is also essential for easy and quick maintenance and cleaning of the extrusion head.

- EASY ACCESS FOR MAINTENANCE FlYer3 is designed for easy maintenance by allowing access to both motors and heating elements without ever having to stop the extrusion line, keeping the ring in ‘automatic’ mode.

- MULTI-STAGE STABILISER A booster stabilizer is available for better bubble stability and higher output.

- TECH 2.0 Profile adjustment is available in a Tech 2.0 version protected by a specific patent. Temperature control and point-to-point air volume control along 360 degrees of the bubble’s circumference are available in alternative or complementary form for maximum flexibility in handling and control capabilities. The combination of the two technologies allows a reduction of up to 75% of the initial profile error.

- LARGE RANGES OF INFLATION RATIOS FlYer3 is suitable for both large and small BUR thanks to its flexible design and dedicated inserts.

- INDUSTRY 4.0 & IoT All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

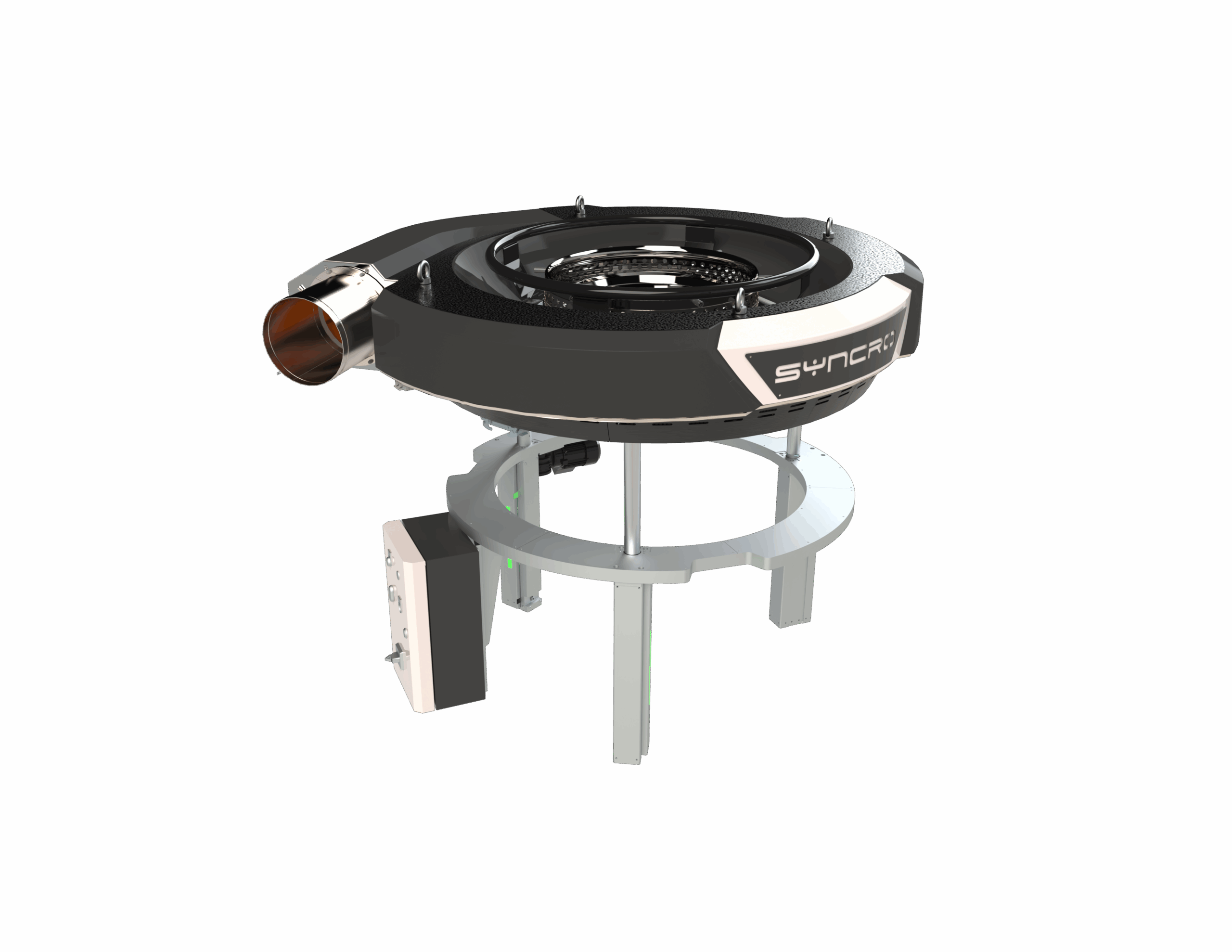

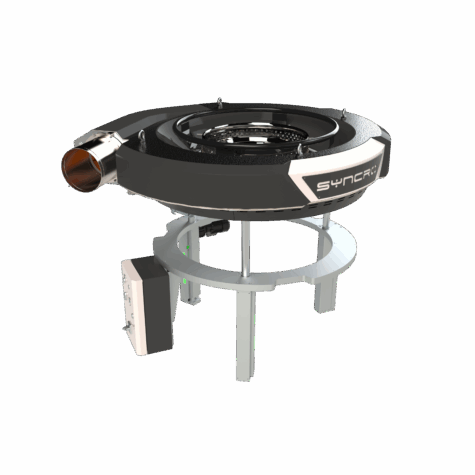

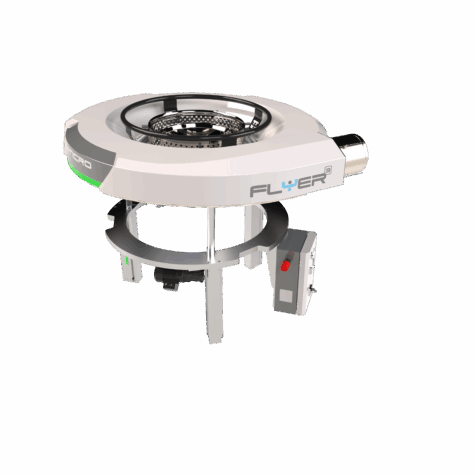

Flyer³

Automatic air ring with outstanding performance

FlYer3, is the cooling ring designed for maximum cooling capacity, productivity, bubble stability, accurate thickness profile control and film quality. FlYer3 represents a true evolutionary step of the cooling ring, justifying the ambitious expression ‘cubed’.