- GRAVIMETRIC EXTRUSION THROUGHPUT The mixer is mounted on two load cells and measures the LIW, controlling the extrusion throughput with continuous reading.

- WIDE RANGE OF SETTING - Due to the different dosing ratios each component can be switched in future from low to high dosing rates.

- CONVEYING SYSTEM - Mybatch can be supplied along with an integrated centralised conveying system controlled by the same PLC of the blender.

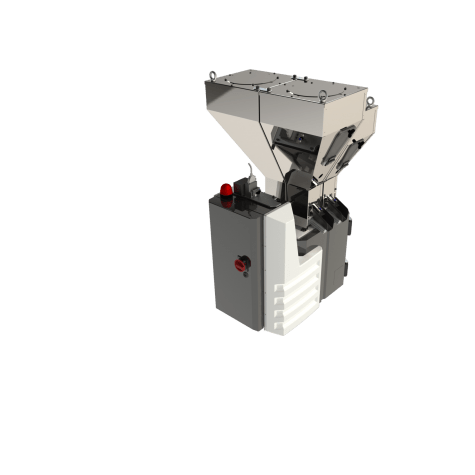

- CLEANING - Easy cleaning thanks to the drain spout installed on each hopper plus a compressed air gun is also included.

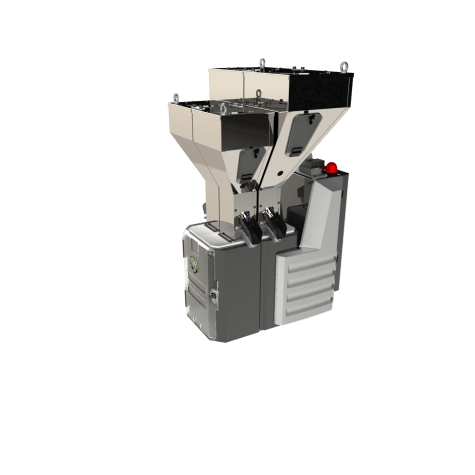

- HMI - The blender can be equipped with a HMI touch screen (5.7” - 7’’ - 10’’) onboard or supplied in a separate box.

- PLC, INDUSTRY 4.0 & IoT - Mybatch has a PLC with protocol UPC/UA embedded. This solution makes each blender modular and ready for Industry 4.0.

- MIXER MOTOR - SYNCRO Mybatch uses a three phase motor for its mixer along with a dry gearbox avoiding any possible motor overheating and oil leaking.

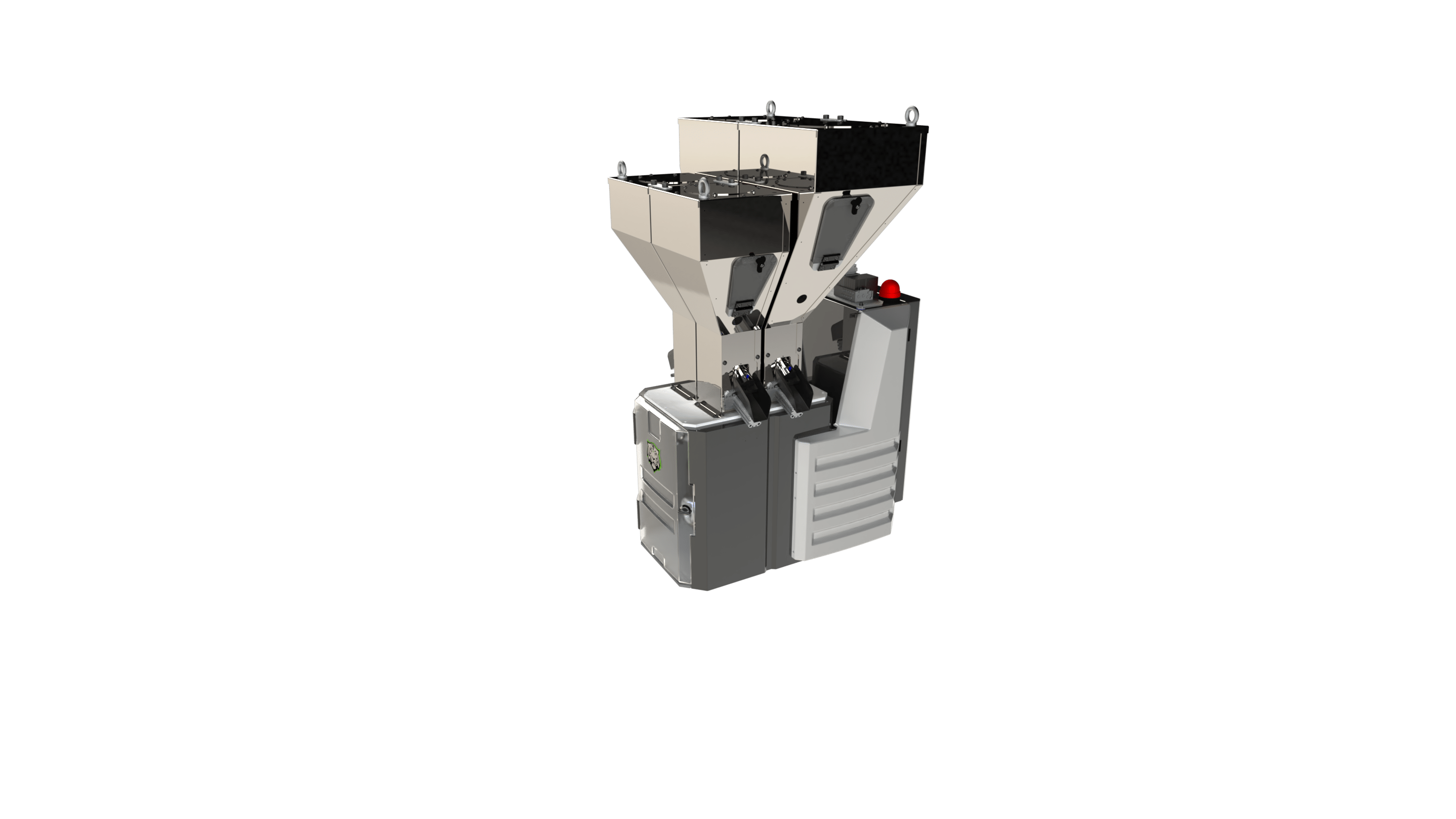

- MODULARITY - Thanks to its design Mybatch can be upgraded in future to allow components to be increased by simply adding the surge hoppers from 2 to 6 components.

- EASY MAINTENANCE - Large opening doors facilitate easy access to the machine for cleaning operations. The reliability of the machine makes it virtually “maintenance free”.

- SMARTDRAYN - As an option MYbatch can be equipped with the automatic draining system SMARTDRAYN.

- EASY CLEANING - As an option MYbatch can be equipped with the mixer installed on linear guides for easy access to the mixing chamber along with the possibility of dismounting the mixer shaft for simple cleaning.

- HT Version - Optionally MYbatch can manage hot materials up to 180°C.

- INDUSTRY 4.0 & IoT - All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

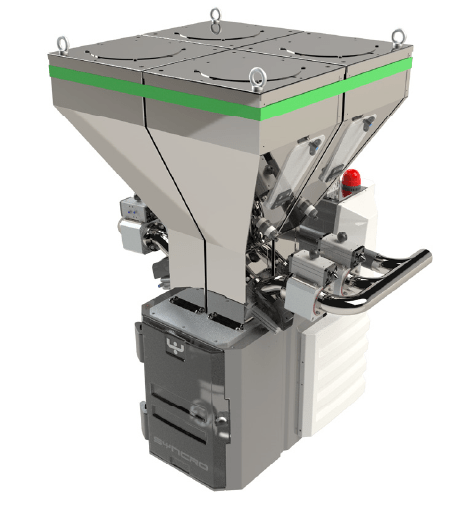

Mybatch

The Innovative Gain-In-Weight Batch Blender

MYBATCH is an innovative gain-in-weight batch blender, designed to dose and blend multiple components in sequence for all processes where constant gravimetric feeding and an homogeneous mix is required.

Each ingredient is metered in sequence by slide gate valves in to the weighing hopper mounted on two load cells. Once the pre-set batch weight has been reached, the load cell sends a signal and the batch is unloaded into the weighing and mixing chamber which combines the batch and the Loss In Weight technology