- COMPREHENSIVE LOSS-IN-WEIGHT CONTROL - monitoring live consumption rate to an extruder and updating process rate every second.

- CONSISTENT ACCURACY - The LIW hopper is suspended on a pair of highly accurate load cells.

- SIMPLE SET UP - Throughput of line is fully automatic and requires no user intervention.

- MAGUIRE + SYNCRO SYNTROL CONTROL - Syntrol touchscreen allows quick and easy setup of extrusion process.

- SPECIALIST EXTRUSION CONTROL - for every type of extrusion process. Easily set process parameters like gram/meter, micron and layer ratios.

- RAW MATERIAL SAVINGS - Overall raw materials savings of up to 10% compared to manual regulation. Optimized process from constant extrusion control.

- REDUCED SCRAP - Reduced start-up material wastage & changeover scrap

- AUTOMATIC - Automatically regulate extruder and haul-off speeds to always be on target.

- ELIMINATE PROCESS VARIATIONS - due to screen pack, voltage fluctuations and MFI differences.

- DATA - Document clearly materials usage and process parameters for quality, process and cost control.

- RETURN ON INVESTMENT - within 6 months. Fast payback by reduced material usage, production scrap, manual intervention and increased productivity.

- RANGE OF MATERIAL - Suited to every application of free-flowing material, pellets, granules or powder.

- RAPID ACCESS - Magnetic retainers on the hopper enclosure allow quick access to the LIW hopper.

- AUDIBLE AND VISUAL ALARMS - Alarms are activated is system is not operating withing required process conditions.

- FASTER-START UP TIME - Switch from manual start-up to automatic and set required output. No further operator involvement.

- QUICK MATERIAL RELEASE - Optional compact drain can be mounted directly below the LIW hopper. Rapid draining of materials.

- SOLUTIONS FOR EXTRUSION PROCESSES - Suited to continuous extrusion processes for mono and co-extrusion processes. Applications include cable, cast film, blown film, sheet, pipe, tube & profile extrusion

- MAGUIRE+SYNCRO CONTROL FLEXIBILITY - Controller allows effective control for mono and co-ex processes, managed from 1 HMI.

- EXPANDABLE & MODULAR - The LIW control is expandable and can be simply integrated with further downstream controls for automatic gauging and process control.

- RETROFIT - LIW extrusion control module can easily be retrofitted with other modular components from Maguire + Syncro including air rings, IBC control, Gauging, and in-line recycling.

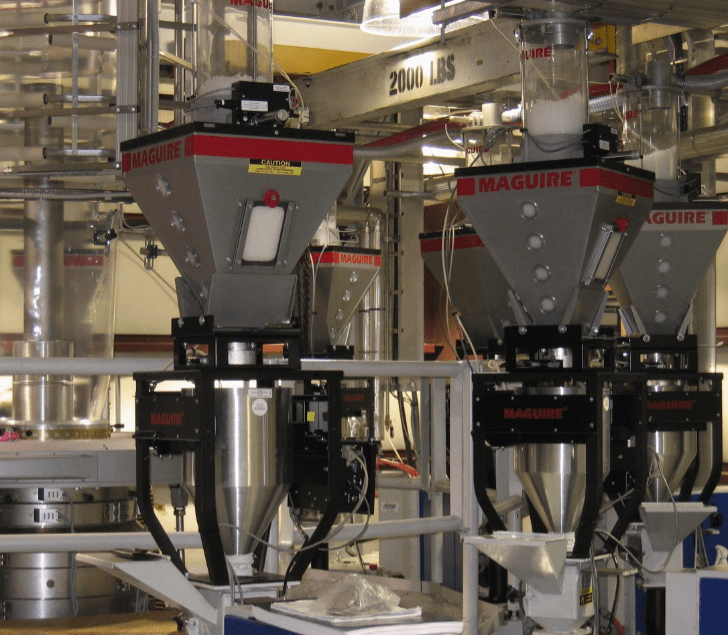

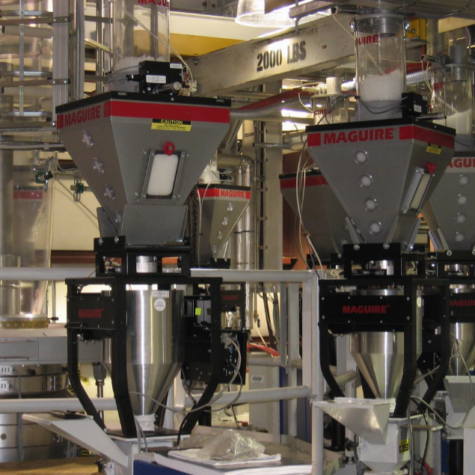

- ADDING MASTERBATCH AND ADDITIVES - Options for incorporating MGF Gravimetric Feeder into Maguire + Syncro control for accurate dosing of masterbatch and additive. • The Maguire MGF series can be used for all extrusion applications. • Fit easy, cost effective control for an additive or masterbatch. • Plugs in and controls directly from Maguire +Syncro control box. • Feeder automatically re-calibrates to new color, so no additional setup required. • Feeder automatically doses according to extrusion throughput reference entered into control. • MGF follows complete process data from LIW live. Loss in weight updates process consumption every second.

SYNCRO GROUP

Ideal partner for plastics processors who require innovative technology to gain a competitive edge.

LIW

LIW Loss-in-Weight hopper is suited to all continuous extrusion processes

The LIW Loss-in-Weight hopper is suited to all continuous extrusion processes, for both mono and co-extrusion processes.

It allows for faster start-up and reduced scrap, while ensuring the correct amount of material flows into the extrusion line.

Category: DOSING

Tags: Extrusion Control, Extrusion line, Extrusion processes, Hopper, layer ratio, Line Master, LIW, Loss in weight, Maguire, Maguire + Syncro, Micron