- Microex SP is capable to process all the standard materials typically used to create fibers, such as PP, PA or PET.

- Its special screw design allows to use standard commercial pellets and the screw extraction system permits the disassembling of the screw in less than 5 minutes, accelerating the cleaning and maintenance operations.

- The line is also composed of a melt pump, a special die in alloy steel characterized by 40 holes of 0,4 mm Ø each, a cooling channel, an ensimage unit, 2 godets, an interlacing jet and a winding unit, to allow the collection of the filament.

- Plug and play designed, the machine works with single phase industrial plug or standard 240V home plug, with a consumption of less than 3 KW. Microex 3D is easy to interface with an ERP or production management software with integration via Industry 4.0.

- An extremely user friendly control panel allows to save and export process data on external USB memory.

- The control panel can also be upgraded with a software that, thanks to the presence of a melt pump in the line, allows to perform filter test.

- This test is widely used for compound and masterbatches in the fiber market, as ISO and ASTM standards require.

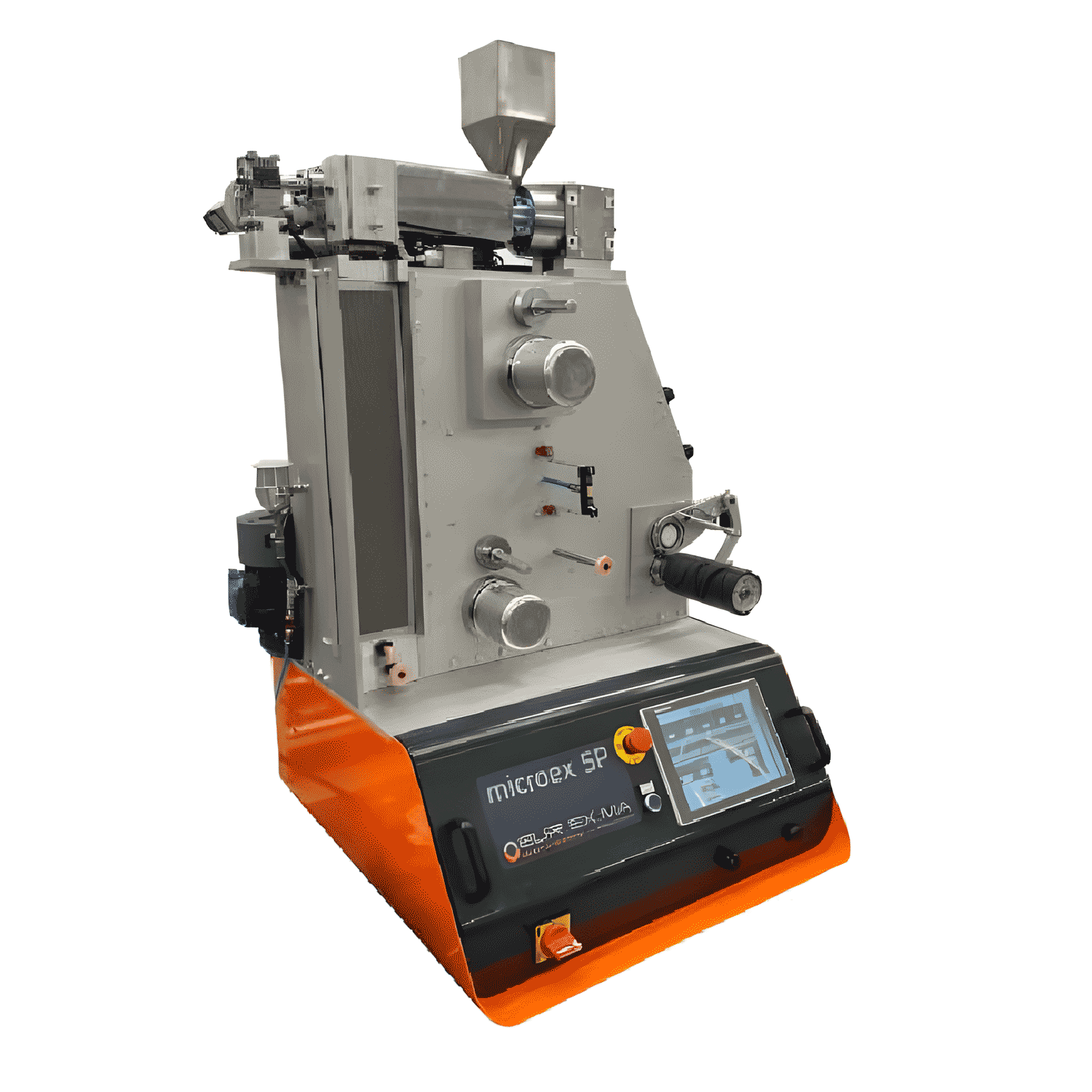

Microex SP

Benchtop Melt Spinning Extrusion Line

Microex 3D is a benchtop line projected for small scale production of filament for 3D printers. Characterized by a 17,5 Ø mm Microex extruder, it can also be used to test the characteristics and formulations of different materials in the production of 3D filament before sending them to serial production

Processes: