- The Microex extruder of the Microex UW, with a special conical screw able to replicate the efficiency of bigger-size screws, is capable to process any kind of polymeric materials.

- Its special screw design allows to use standard commercial pellets and the screw extraction system permits the disassembling of the screw in less than 5 minutes, accelerating the cleaning and maintenance operation.

- The screw and the barrel are realized in K110 nitrated steel in order to avoid corrosion and wear problems. The extruder is also characterized by 2 thermo-regulated zones, useful to set the desired temperature and ensure a good process quality.

- Plug and play designed, the machine works with single phase industrial plug or standard 240V home plug, with a consumption of less than 3 KW.

- An extremely user friendly control panel allows to save and export process data on external USB memory.

- Microex UW is easy to interface with an ERP or production management software with integration via industry 4.0.

- This line represents an optimal solution to perform quality tests, particularly on color and compound formulations, with low consumption and waste.

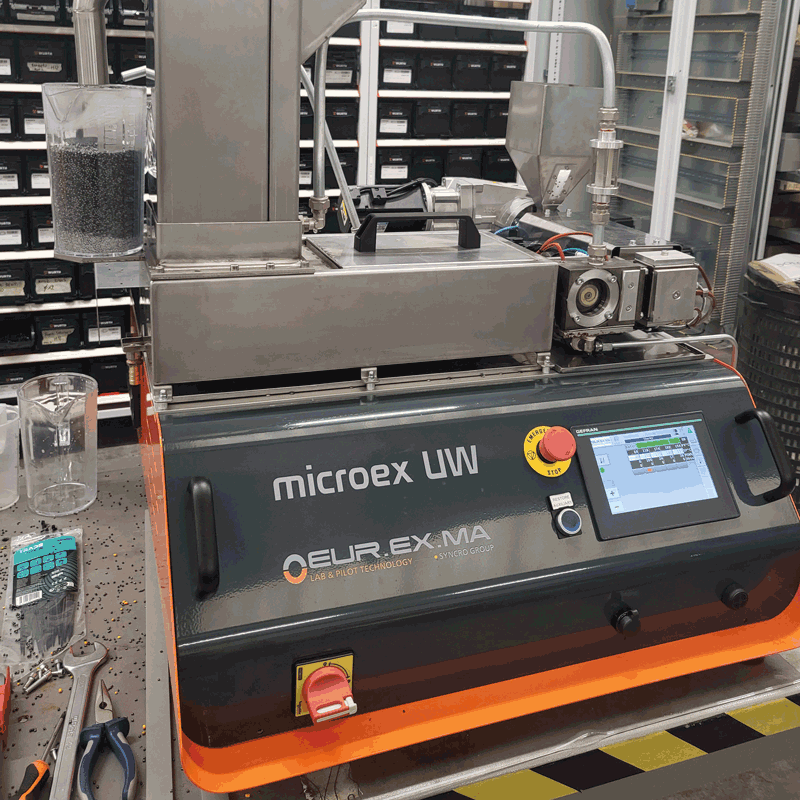

Microex UW

Benchtop Underwater Compounding Line

Microex UW is a benchtop underwater compounding line capable to create small samples of granules of polymeric materials with low amount of granules or powder. The line is equipped with an underwater die face cutting unit, optimal solution to process all the thermoplastic materials

Processes: