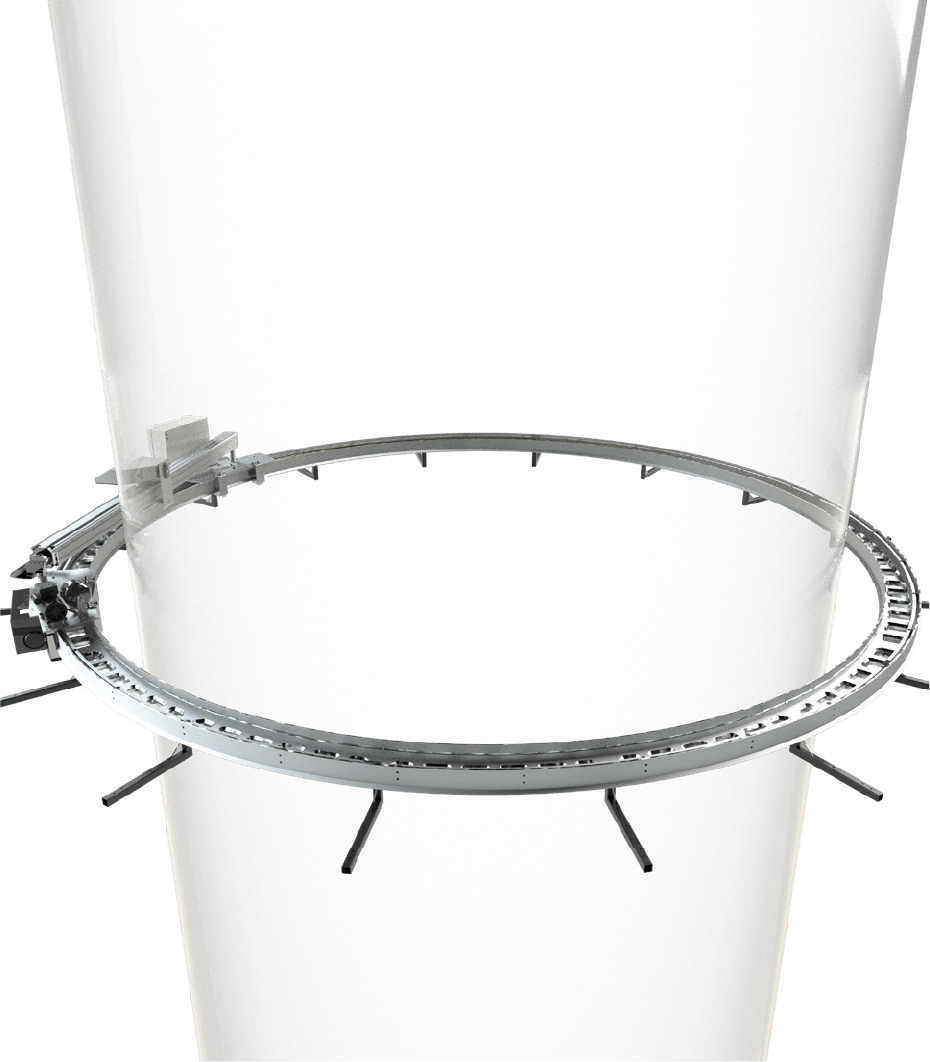

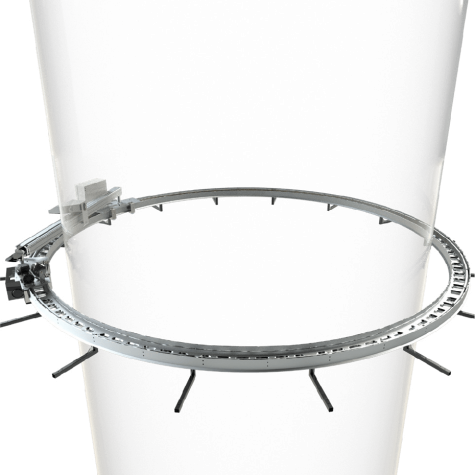

- PATENTED TRIPLE TELESCOPIC SYSTEM The triple telescopic system is built with a patented precision mechanism (Patent WO2015/155621) and is positioned on two motorized trolleys that generate the movement around the extruded bubble.

- MULTIPLE MEASUREMENT TECHNOLOGIES One of the following sensors can be accommodated in the centre of the intermediate element of the threestage telescopic beam: • Capacitive contact • Capacitive no contact • Xray Backscatter ideal for barrier structure.

- MOTORISED MOVEMENT SkYmex fulfils four basic requirements: rigidity, absence of vibration, wide radial measurement range and minimal overall dimensions during rotation. Thanks to the passive beam and the two motorised carriages that synchronise during rotation, the sensor is kept in the centre plane of the carriages regardless of the bubble diameter, guaranteeing wide BUR ranges.

- ULTRASONIC DISTANCE SENSOR SkYmex is equipped with an ultrasonic sensor that ensures that the set distance between the sensor and the bubble is maintained.

- WIDE MEASURING RANGE Each SkYmex model can adapt to the bubble diameter up to a ratio of 4:1 between maximum and minimum diameter. Thanks to the numerous construction sizes, layflats from 4.5 up to 14 metres are available. For layflats smaller than 4.5 metres, the standard SkYmex is available.

- INDUSTRY 4.0 & IoT All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Skymex wide

Thickness gauge for blown extrusion

SKYMEX WIDE CONTACT / NO CONTACT is a capacitive thickness gauge for bubble extrusion lines. It ensures continuous and accurate measurement of the film thickness profile detected by oscillating or rotating around the bubble. It uses a patented triple movement telescope.

The machine can use either capacitive or backscatter X-ray sensors. In the first case, the dielectric characteristics of the measured film produce a signal variation proportional to film thickness. In the second, which is suitable for products containing PA or EVOH, the signal is attenuated by the absorption of radiation proportional to film thickness. The sensor is mounted in the centre of the beam, the oscillatory rotation of the system around the bubble and the reading of the angular position allow a circumferential profile of the thickness to be generated over 360°.