- ACCURACY - Accuracy less than 0.3% of the measured value, with resolution 0.02 micron.

- NON RADIOACTIVE - SonYcscan doesn’t require any attenction relating the operator safety. It doesn’t use any type of ionizing radiation.

- SYNTROL CONTROL - SonYcscan is controlled by a SYNTROL supervision system including PC touch screen, keyboard, mouse and printer.

- PROCESSES - SonYcscan can be used on different process such as stretch film lines, non-woven lines, BOPP lines, coating lines.

- CALIBRATION - Automatic calibration and setup. No calibration standard required for different materials.

- LIMITLESS PERFORMANCE - The SonYcscan calculates the basis weight in real time regardless of material, color, position and is suitable for paper, metals, plastic, technical fleece, fabrics and many more.

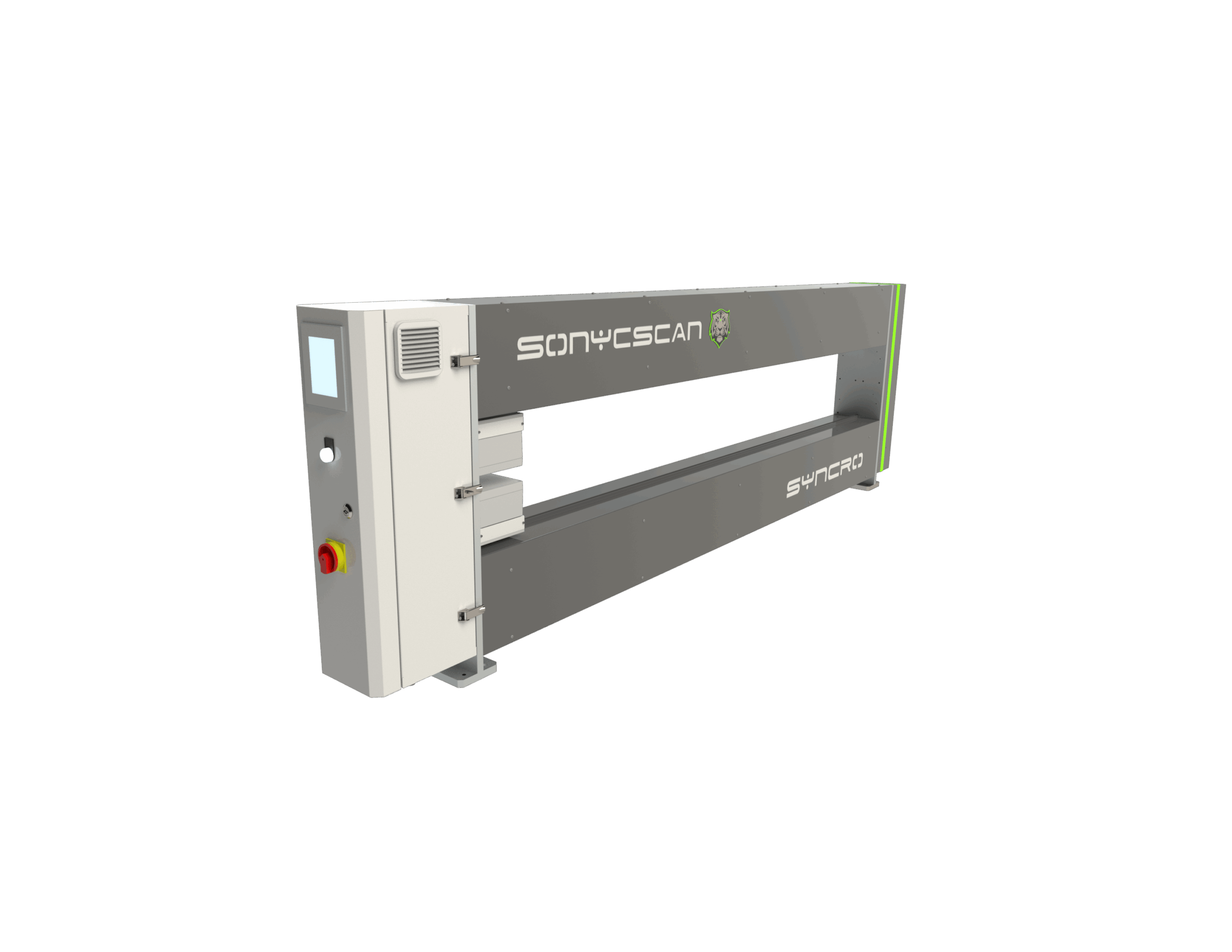

- HEAVY DUTY STRUCTURE - The heavy duty engineering offers excellent resistance to bending of the main frame and guarantees perfect measurement stability.

- EASY ACCESS FOR MAINTENANCE - The SonYcscan as been designed to guarantee easy access for maintenance operations. Long lifetime, easy to clean, rugged and robust sensor. Very small field of view (small measurement spot). Laboratory unit with passage device for samples available.

- FAST SET UP - The average start up is done in less than 2h.

- STABLE AND PRECISE - Extremely stable and precise measurement: down to 0.02 micron of repeatibility. Internal compensation of the temperature and humidity of the scanning heads and of the measurement gap guarantee the correct measurement in different conditions of use.

- AUTO PROFILE CONTROL - As option SonYcscan can be connected to SYntrolgauge to control automatically the thermal bolts used on flat dies or automatic air ring on blow film lines to regulate the film/sheet profile.

- INDUSTRY 4.0 & IoT - All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Sonycscan

Ultrasonic Gauging System

The SONYCSCAN is based on the ultrasonic adsorption measurement method to measure the thickness, usually shown in μm or in g/m2.

A custom Ultrasonic source is situated in a housing, while another housing contains the receiver and is positioned opposite the transmitter at a set distance (Gap). Using a series of special software procedures that measure the material’s wave travel times and signal attenuation levels, compensating the measurements for thermal drifts and local humidity variations, the system is able to detect the thickness/weight of the material.