- DRYING TIME - Vacuum reduces the boiling point of the water. Vacuum is the fastest way to remove the humidity. The drying time is reduced up to 50%.

- ENERGY CONSUMPTION - The yield of the infrared radiation under vacuum increases by up to 30% compared to the same radiation in air. The direct heating by IR is the most efficient way to heat a body. The combination of IR and vacuum guarantees the maximum energy efficiency.

- ACCURACY - Temperature control is precise as VHELYOS directly heats the material and controls its temperature. The reactor works in batch mode mixing the material under treatment. At the end of the process, every single particle is in the same condition of temperature and humidity.

- COSTS OF MAINTENANCE AND OPERATION - The dehumidification is carried out with the action of the vacuum, whereby the humidity – but also the ethylene glycol and any other contaminants – are extracted from the recycled PET and evacuated towards the outside. Therefore, unlike a traditional system, the work circuit is “open”: there are no molecular sieves or condensing units, i.e. there are no parts of the system that degrade and require a production shutdown for their maintenance / cleaning . In this way, the FYNISHER manages to reduce maintenance costs and ensure continuous operation.

- MATERIALS ALLOWED - The combination of IR, vacuum and mixing allows to process pellets, regrinds, irregular shapes, dusty materials or a mix of them.

- OXIDATION - The whole process of drying and even the storage are done under vacuum, so preventing any contact of the material with oxygen. Aft.er the treatment, the material can be stored under vacuum for indefinite time with no risk of oxidation or re absorption of humidity.

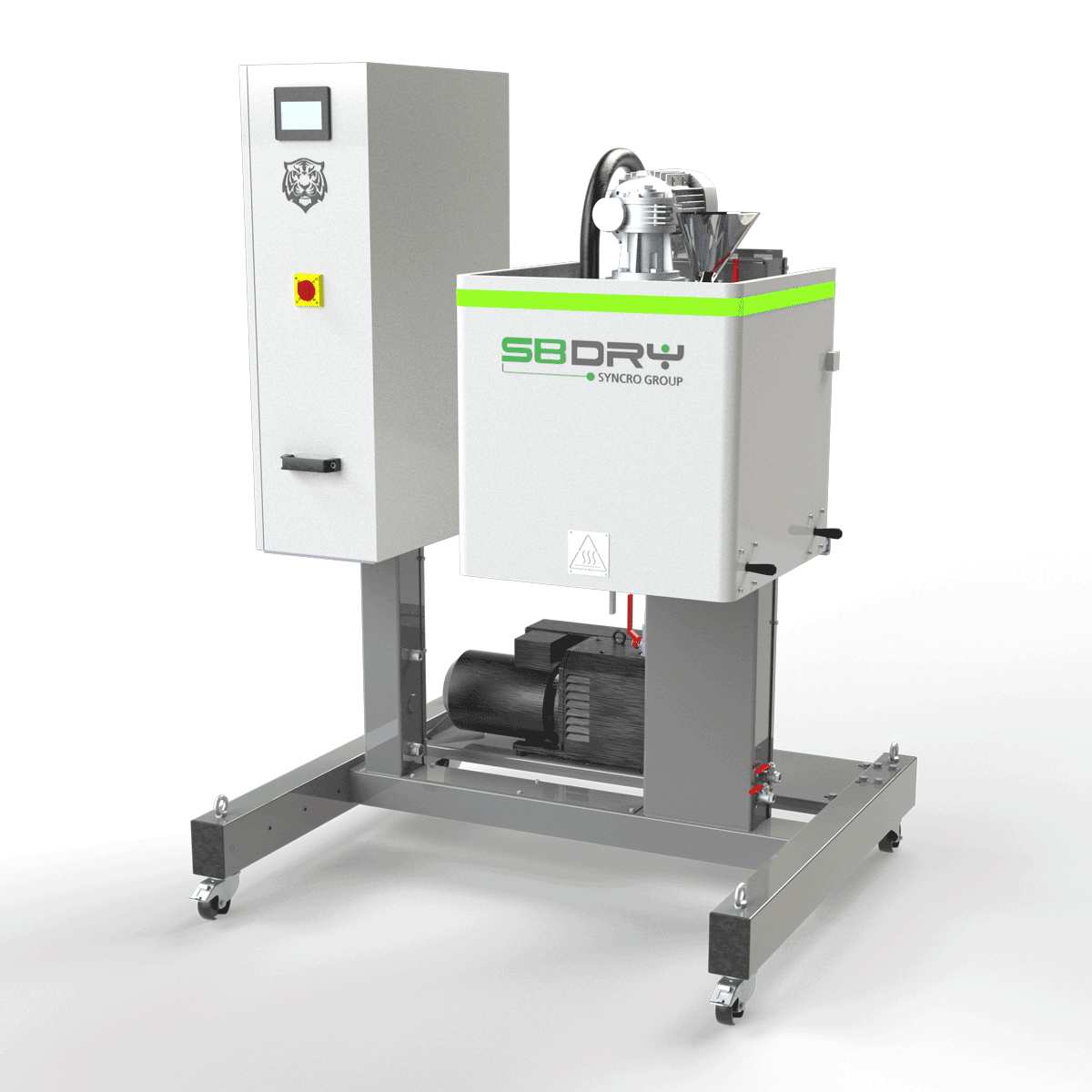

- INDUSTRY 4.0 & IoT - All SB DRY machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

SYNCRO

Ideal partner for plastics processors who require innovative technology to gain a competitive edge.

Vhelyos

Super-Drying

Extreme dehumidification solutions for the most difficult plastic materials.

The super-dehumidifiers of the VHELYOS series use an irradiation heating system, thanks to which the energy is transferred directly to the material, therefore without any “medium” that could alter the nature of the plastic polymer. The humidity, on the other hand, is extracted with the application of the vacuum up to a residual pressure lower than 0.1 mbar. The result of this combination of radiation and “stripping” allows VHELYOS super-dehumidifiers to obtain extreme levels of dehumidification, quickly, with low energy consumption, without oxidation and in any case without interference of foreign agents with the plastic polymer.