- COOLING AND HOMOGENEITY - The extended ambient cooling system around the bubble allows an effective reduction of the film temperature by up to 15 °C compared to the case without Zyroblock. The system also ensures uniform cooling around the bubble because the air flows are not oriented directly against the bubble but they are enveloped entirely during the ascent.

- EASY INSTALLATION - Zyroblock can be integrated with the SYNCRO bubble cage in order to create an all in one system or it can be installed as a stand-alone version on an existing extrusion line with a bubble cage.

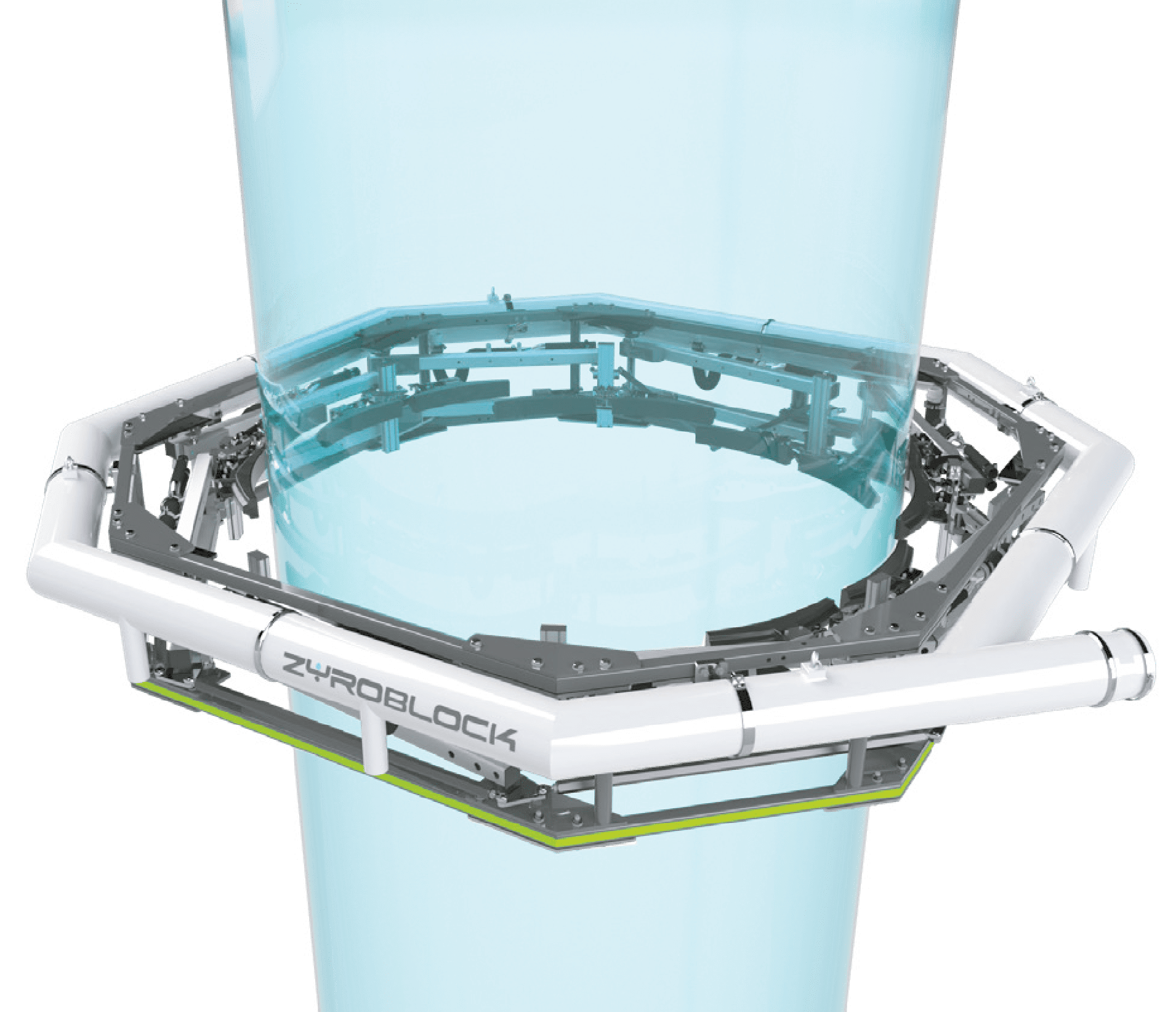

- PATENTED MOVEMENT - Zyroblock has a patented opening and closing movement that keeps the radial nozzles always referenced to the centre of the bubble even during adjustment, maintaining the uniformity and perpendicularity of the flows and ensuring the maximum homogeneity.

- VARIABLE BLOWER GEOMETRY - Like every bubble cage, Zyroblock has a controlled movement to open and to close the cage according to the diameter of the bubble during the production. Each blower nozzle is composed of two blowers elements arranged symmetrically to the right and left of the moving arm that supports them. The opening and closing movement passively produces an angle variation between two symmetrical blowers by adapting the position of the blowers to the bubble curvature of the bubble is (see detail A in the picture on the next page).

- CONTROL OF THE COOLING - IR sensors, installed at the input and output, make it possible to adjust the amount of the cooling (airflow and temperature) in order to control the temperature of the bubble which is coming in the haul-off.

Zyroblock

System for additional cooling

ZYROBLOCK is the system for additional bubble cooling, which it is essential in plants and production lines where the bubble reached hot temperature at the nip and there is a risk of blocking in the haul-off.

The system is placed after the frost line and just before the collapsing frames or it can be integrated into the bubble cage. The cold air flows blown around the surface of the bubble, remove hot air coming from below the areas and, at the same time, create a cooled environment around the bubble in order to bring down the temperature of the film.