- MAXIMISES PRODUCTIVITY - ZYrowax combined with the VortYx IBC, maximizes line productivity by reducing bubble break hazards due by monomer residue drips and the frequency of line stops for cleaning.

- ZERO IMPACT ON THE BUBBLE - The system exploits the natural diffusion flow of the monomers, therefore effectively sucking them out without having to create a lot of pressure difference: this way ZYrowax doesn’t impact the air ring cooling flow, and so the stability of the bubble is not affected by its presence.

- EASY CLEANING - Cleaning operations do not require downtime and are facilitated by a rational map of evacuation connections.

- BETTER AIR QUALITY - The installation of ZYrowax also provides a healthier environment for line operators when entering the headroom.

- MINIMUM SPACE REQUIREMENT - ZYrowax allows cleaning and maintenance access to the hot part and adjacent structures of the extrusion line.

- FAST RETURN ON INVESTMENT - It is an accessory with a very competitive investment price compared to the process benefits it brings to production.

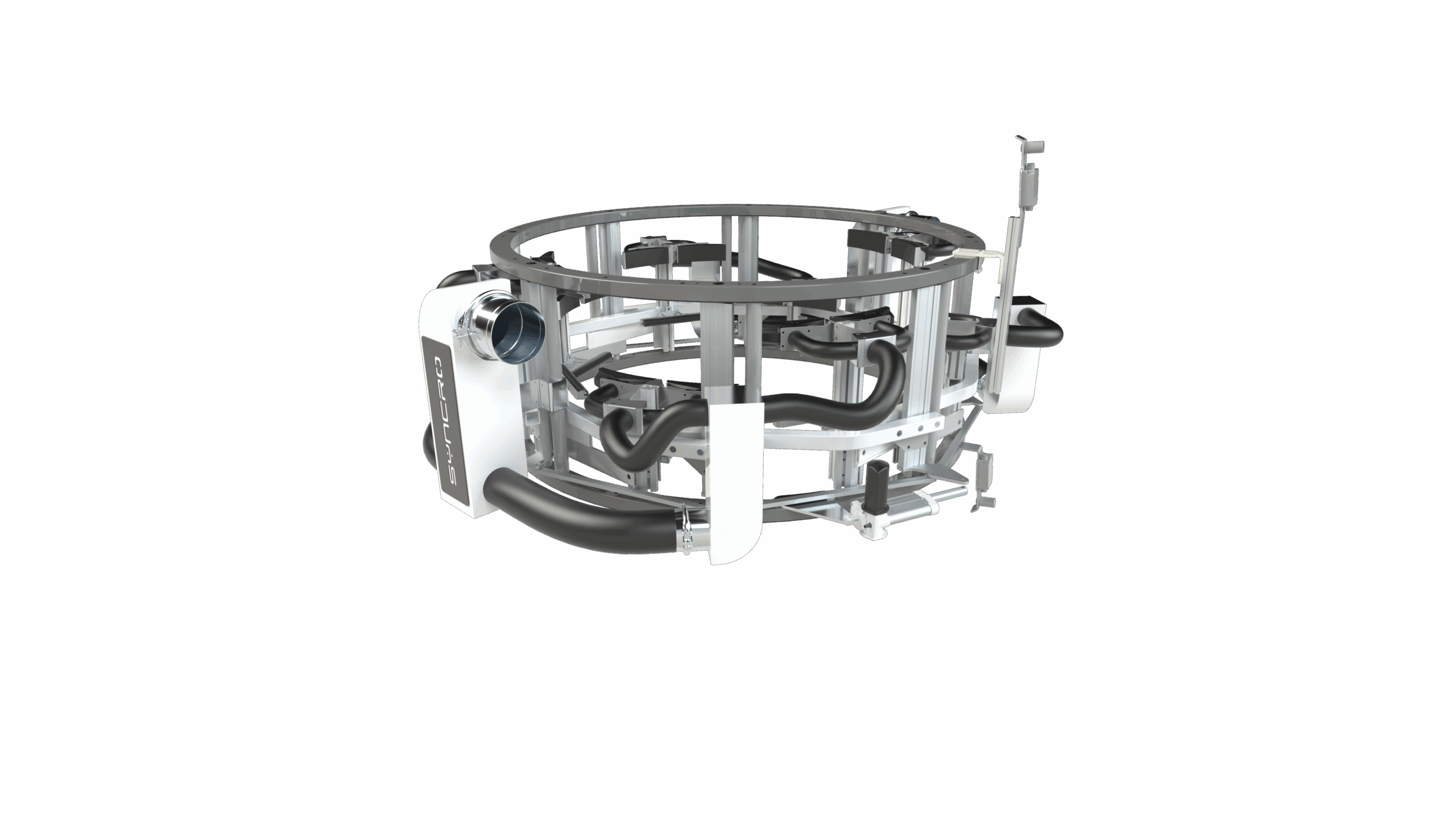

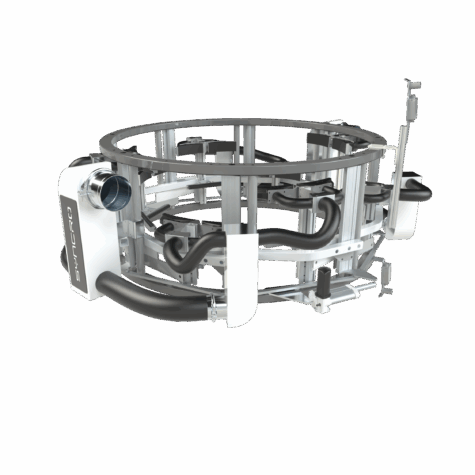

- MAXIMUM COMPATIBILITY - Possibility of installation on existing SYncro rings working on existing bubble extrusion lines.

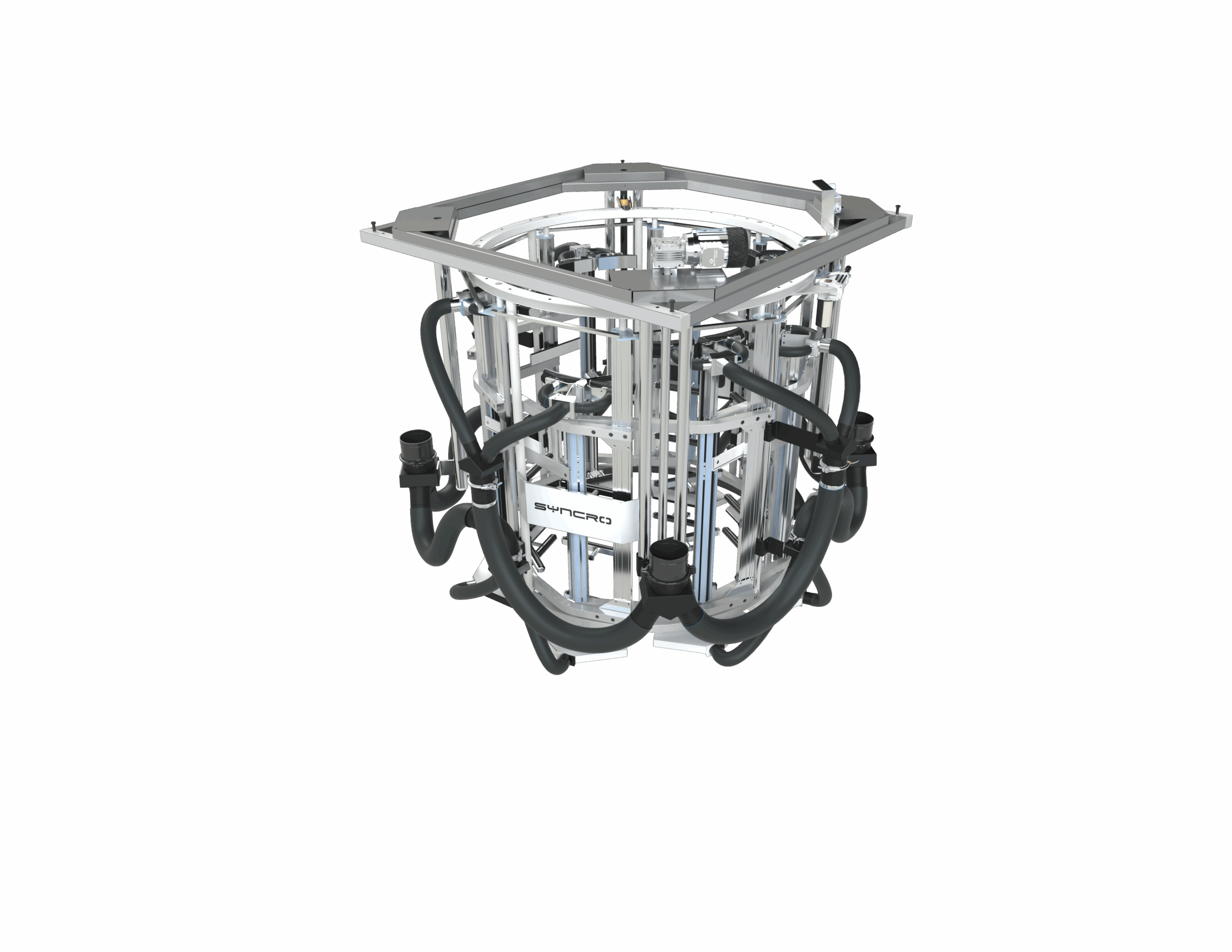

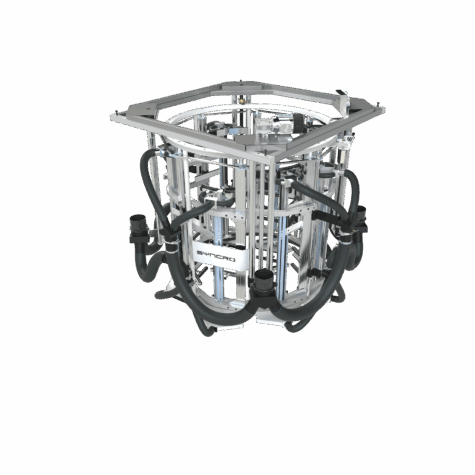

Zyrowax

Monomer Purification System

ZYROWAX is a suction system for the monomers generated by the melt escaping from the extrusion head at high temperature.

The system filters the monomer particles, preventing them from diffusing in the ambient and then condensate on every surface thus improving the air quality and the productivity, as it allows longer time intervals between line stops for maintenance and cleaning.

A series of vents is placed between the die and the lower side of the air ring, and is connected to a suction fan. The intaken air flows through the filters placed in the vents and is purified from the monomer vapours.