- NON RADIOACTIVE - Following the EURATOM guidelines, RaYxscan is recognised as a radioactive resource exempt from the requirement for a safety certificate, since during its activity remains below 5 keV and it does not have doses above the minimum safe threshold.

- INDUSTRY 4.0 & IoT - Rayxscan is equipped with PLC integrated with OPCUA protocol for industry 4.0.

- SYNTROL CONTROL - RaYxscan is controlled by the SYNTROL supervisory system capable of visualisation, history and adjustments.

- PROCESSES - RaYxscan can be used on different process such as stretch film lines, non-woven lines, BOPP lines, coating lines, Blown film lines.

- LIMITLESS PERFORMANCE - The measurement is not influenced by the color or the transparency of the material.

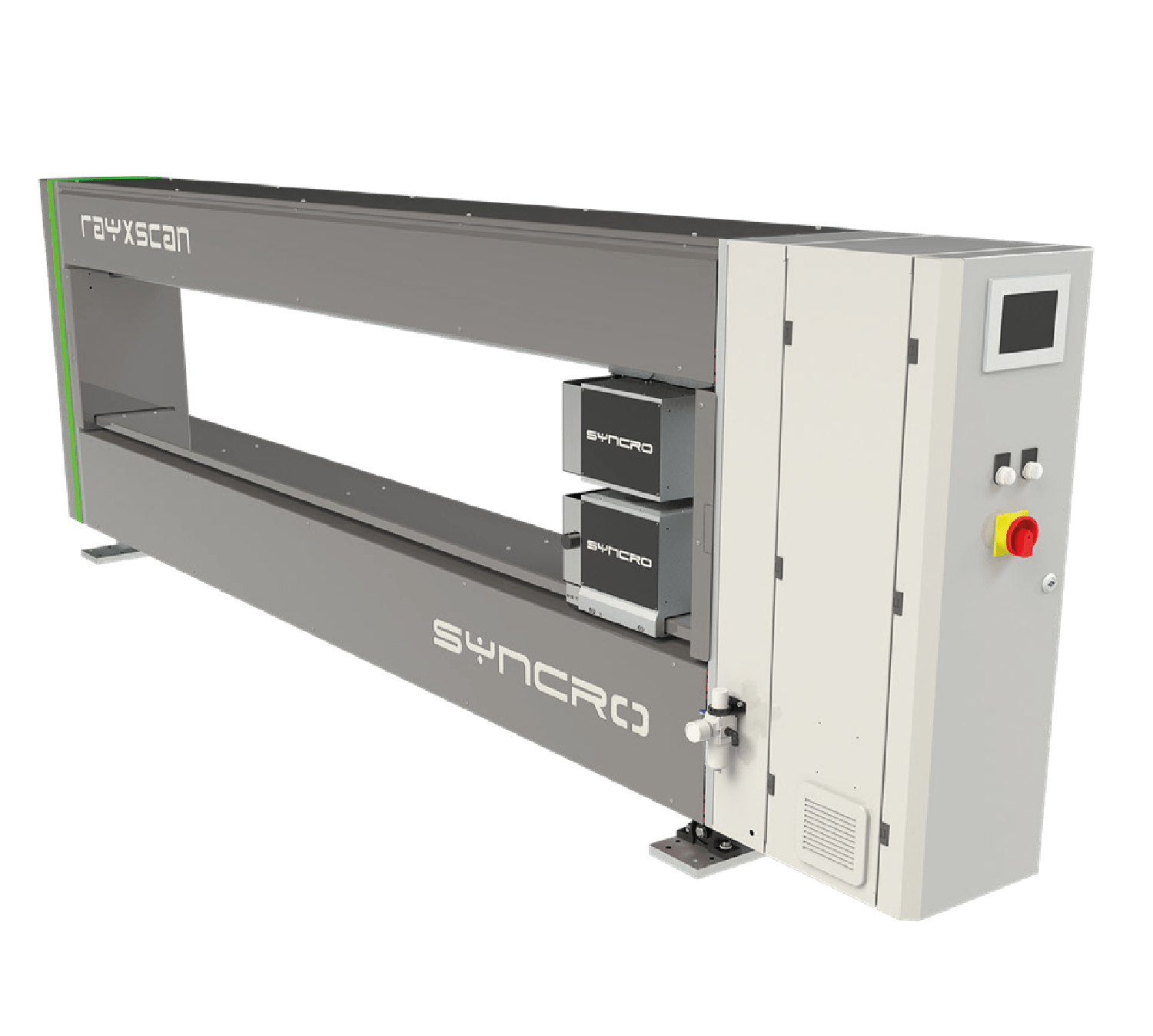

- HEAVY DUTY STRUCTURE - The heavy duty engineering offers excellent resistance to bending of the main frame and guarantees perfect measurement stability.

- EASY ACCESS FOR MAINTENANCE - The RaYxscan has been designed to guarantee easy access for maintenance operations.

- FAST SET UP - The average start up is done in less than 2h.

- STABLE AND PRECISE - Extremely stable and precise measurement: down to 0.02 micron of repeatibility with a max. drift of 0.085 microns in 12h without standardization. Temperature stabilization of the scanning heads and real air gap compesation is readied through an inductive sensor.

- AUTO PROFILE CONTROL - As option RaYxscan can be connected to SYntrolgauge to control automatically the thermal bolts used on flat dies or automatic air ring on blow film lines to regulate the film/sheet profile.

- INDUSTRY 4.0 & IoT - All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Rayxscan

X-Ray Gauging System

The RAYXSCAN uses an X ray beam transmission through the homogeneous material to be measured, from which it can measure the thickness, usually shown in micron or the weight [g/m2].

An X-ray source is situated in a housing, while another housing contains the receiver and is positioned opposite the transmitter at a set distance (Gap). When a homogeneous layer of material is positioned between the transmitter and receiver, part of the energy transmitting to the receiver is absorbed by the material. The part which is not captured by the receiver is directly proportional to the thickness of the measured film according to the main features of the material.