- INTEGRATED CONTROL - SYLINK can be controlled by the SYNCRO dosing unit HMI panel

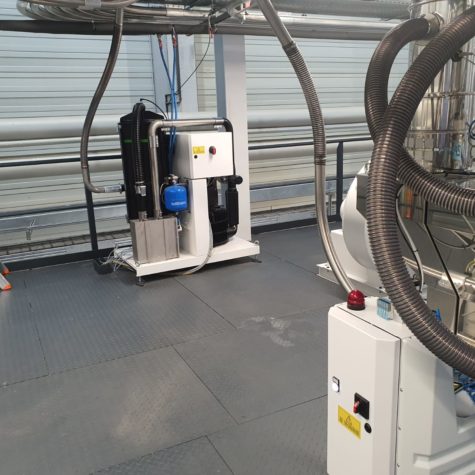

- MAINTEINANCE FREE MOTOR - SYLINK uses a single stage side channel pump which requires virtually no maintenance.

- EASY INSTALLATION - SYLINK can easily be installed on any extrusion line, replacing old vacuum units

- BY-PASS VALVE - SYLINK has a bypass valve which prevents frequent start/stop of the pump increasing the life time of the motor and reducing power consumption.

- AUTO FILTER - As an option, SYLINK can be supplied with a self-cleaning Polyester cartridge filter and air pulse cleaning jet.

- HT VERSION - SYLINK is available in a HT version in order to manage hot polymers up to 180°C via a water heat exchanger installed on the unit.

- SIZES & PERFORMANCES Sylink is available in various sizes: 2,2 Kw - 3 Kw single stage 5,5 Kw - 11 Kw double Stage 11 Kw triple Stage

- MICRO PLC When not connected to a SYNCRO dosing unit SYLINK can be supplied with a micro PLC for control.

SYNCRO GROUP

Ideal partner for plastics processors who require innovative technology to gain a competitive edge.

Sylink

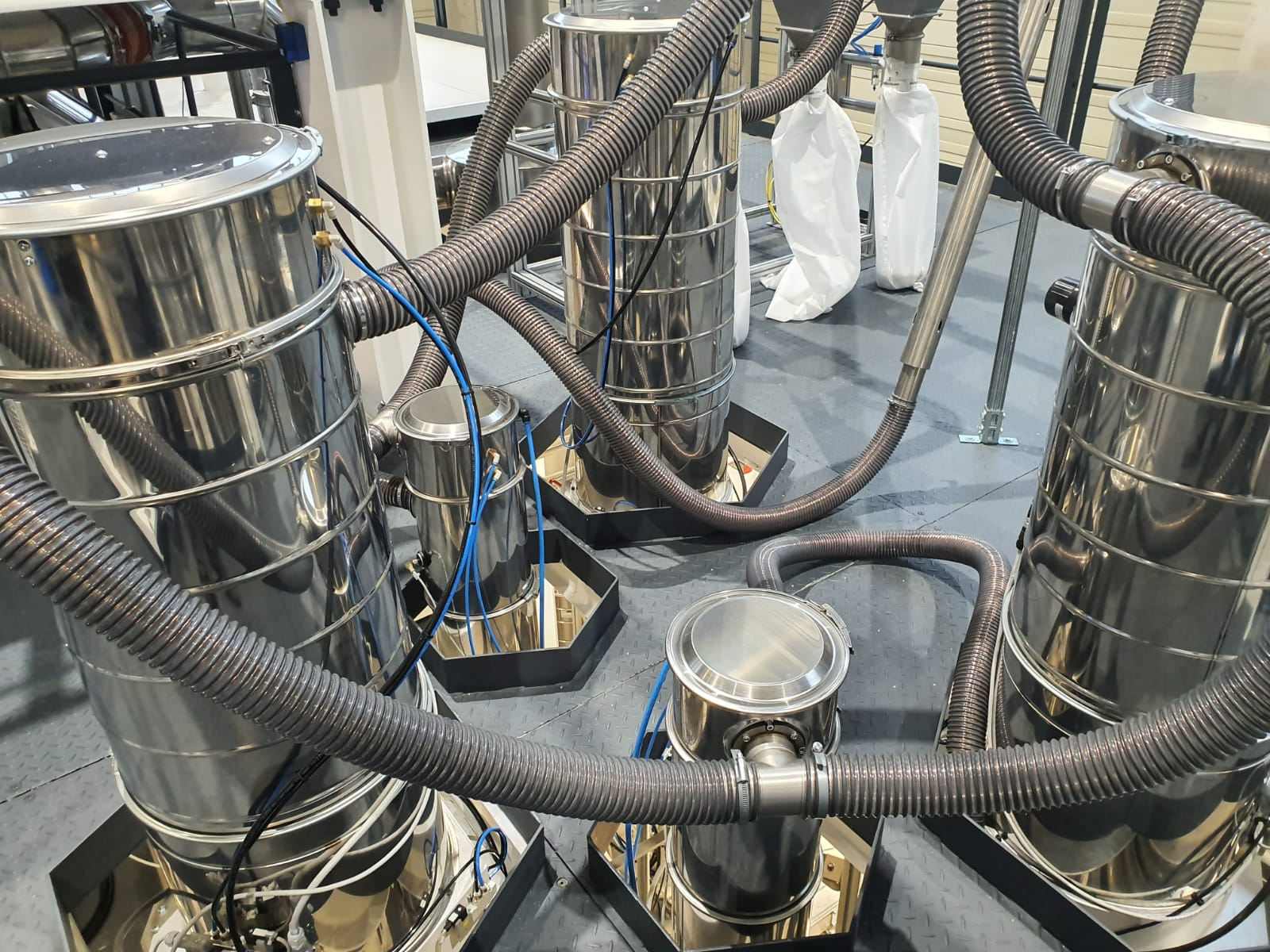

Centralized Vacuum Loading System

SYLINK is a centralized material conveying system that can be linked and managed from any of SYNCRO’s dosing systems.

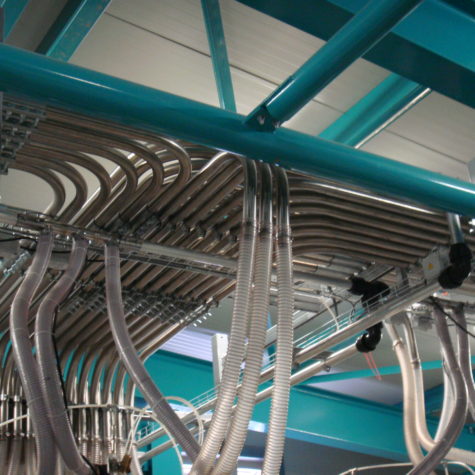

SYLINK is modular and compatible with any side channel blowers types E.g. Single-stage, double-stage, or triple-stage and available with either manual or automatic filtering systems and Syncro’s SYLOAD hopper loaders.

The blower is connected to the SYLOAD hopper loaders through a vacuum ring which performs the material conveying.