- COMPREHENSIVE LOSS-IN-WEIGHT CONTROL - monitoring live consumption rate to an extruder and updating process rate every second.

- CONSISTENT ACCURACY - The LIW hopper is suspended on a pair of highly accurate load cells.

- SIMPLE SET UP - Throughput of line is fully automatic and requires no user intervention.

- MAGUIRE + SYNCRO SYNTROL CONTROL - Syntrol touchscreen allows quick and easy setup of extrusion process.

- SPECIALIST EXTRUSION CONTROL - for every type of extrusion process. Easily set process parameters like gram/meter, micron and layer ratios.

- RAW MATERIAL SAVINGS - Overall raw materials savings of up to 10% compared to manual regulation. Optimized process from constant extrusion control.

- REDUCED SCRAP - Reduced start-up material wastage & changeover scrap

- AUTOMATIC - Automatically regulate extruder and haul-off speeds to always be on target.

- ELIMINATE PROCESS VARIATIONS - due to screen pack, voltage fluctuations and MFI differences.

- DATA - Document clearly materials usage and process parameters for quality, process and cost control.

- RETURN ON INVESTMENT - within 6 months. Fast payback by reduced material usage, production scrap, manual intervention and increased productivity.

- RANGE OF MATERIAL - Suited to every application of free-flowing material, pellets, granules or powder.

- RAPID ACCESS - Magnetic retainers on the hopper enclosure allow quick access to the LIW hopper.

- AUDIBLE AND VISUAL ALARMS - Alarms are activated is system is not operating withing required process conditions.

- FASTER-START UP TIME - Switch from manual start-up to automatic and set required output. No further operator involvement.

- QUICK MATERIAL RELEASE - Optional compact drain can be mounted directly below the LIW hopper. Rapid draining of materials.

- SOLUTIONS FOR EXTRUSION PROCESSES - Suited to continuous extrusion processes for mono and co-extrusion processes. Applications include cable, cast film, blown film, sheet, pipe, tube & profile extrusion

- MAGUIRE+SYNCRO CONTROL FLEXIBILITY - Controller allows effective control for mono and co-ex processes, managed from 1 HMI.

- EXPANDABLE & MODULAR - The LIW control is expandable and can be simply integrated with further downstream controls for automatic gauging and process control.

- RETROFIT - LIW extrusion control module can easily be retrofitted with other modular components from Maguire + Syncro including air rings, IBC control, Gauging, and in-line recycling.

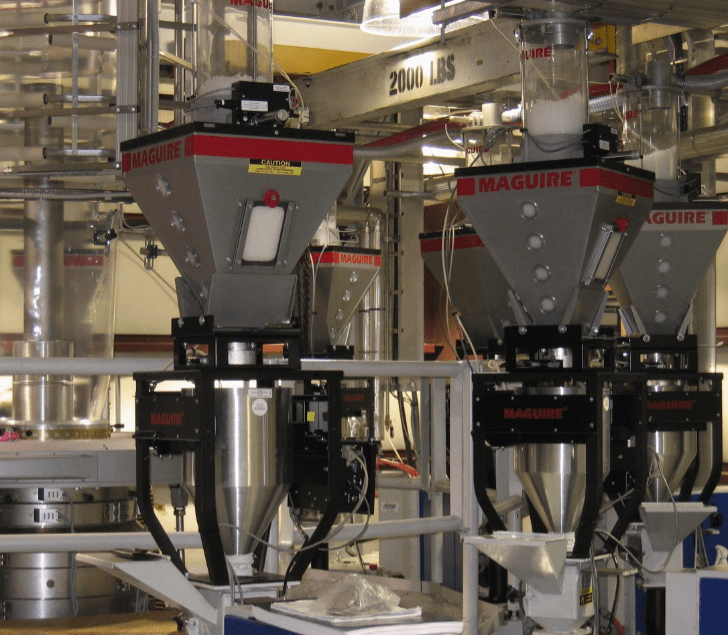

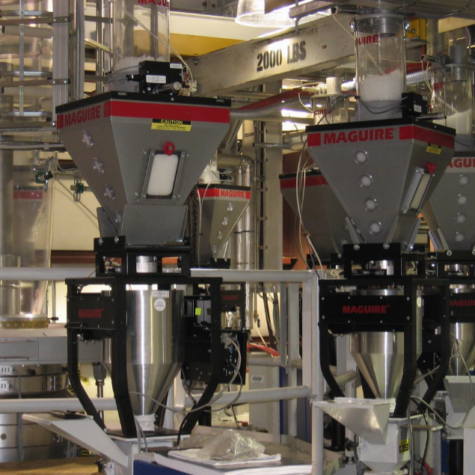

- ADDING MASTERBATCH AND ADDITIVES - Options for incorporating MGF Gravimetric Feeder into Maguire + Syncro control for accurate dosing of masterbatch and additive. • The Maguire MGF series can be used for all extrusion applications. • Fit easy, cost effective control for an additive or masterbatch. • Plugs in and controls directly from Maguire +Syncro control box. • Feeder automatically re-calibrates to new color, so no additional setup required. • Feeder automatically doses according to extrusion throughput reference entered into control. • MGF follows complete process data from LIW live. Loss in weight updates process consumption every second.

SYNCRO

Socio ideal para los transformadores de plásticos que requieren tecnología innovadora para obtener una ventaja competitiva.

LIW

LIW Loss-in-Weight hopper is suited to all continuous extrusion processes

The LIW Loss-in-Weight hopper is suited to all continuous extrusion processes, for both mono and co-extrusion processes.

It allows for faster start-up and reduced scrap, while ensuring the correct amount of material flows into the extrusion line.

Categoría: DOSIFICACIÓN

Etiquetas: Extrusion Control, Extrusion line, Extrusion processes, Hopper, layer ratio, Line Master, LIW, Loss in weight, Maguire, Maguire + Syncro, Micron