- HEAT EXCHANGE MAXIMIZED

- HOURLY PRODUCTION INCREASED

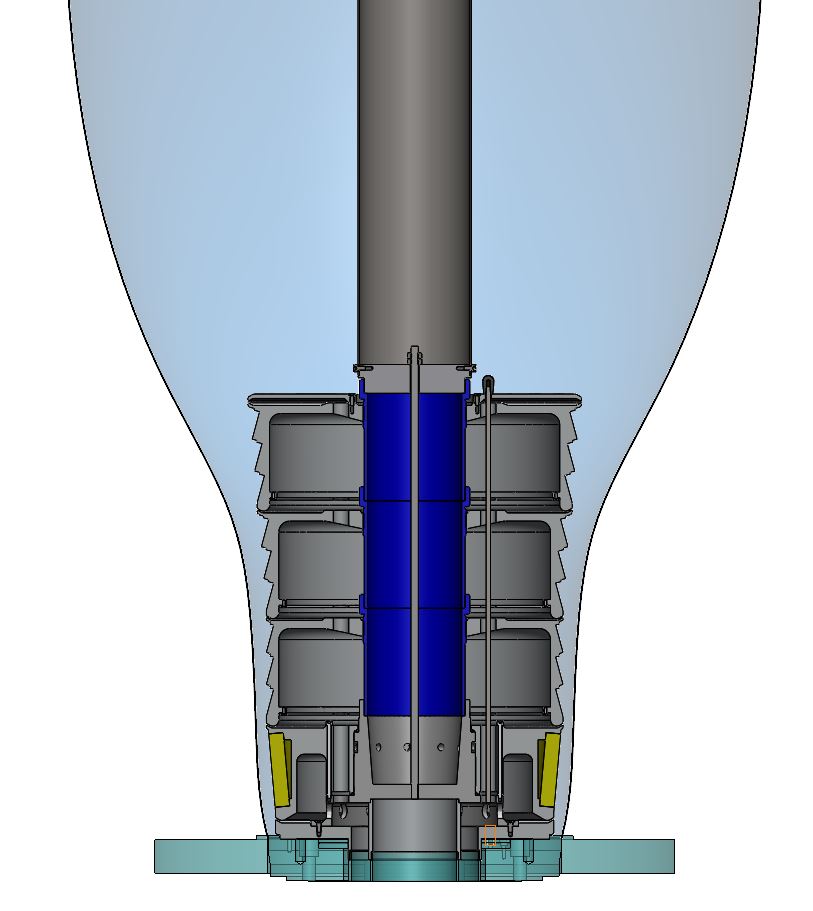

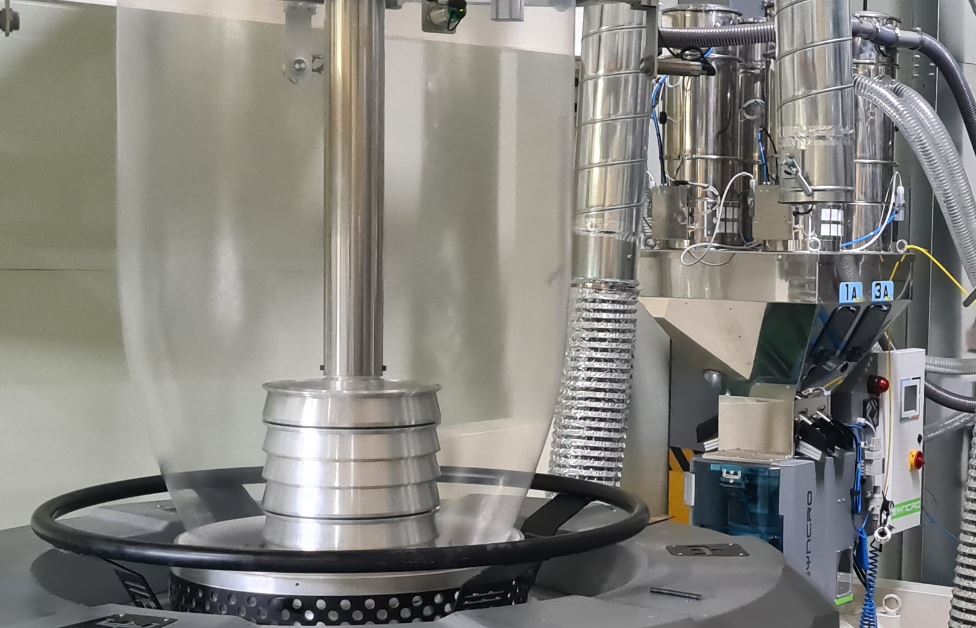

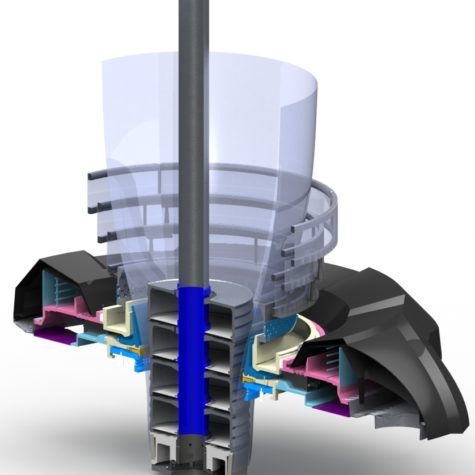

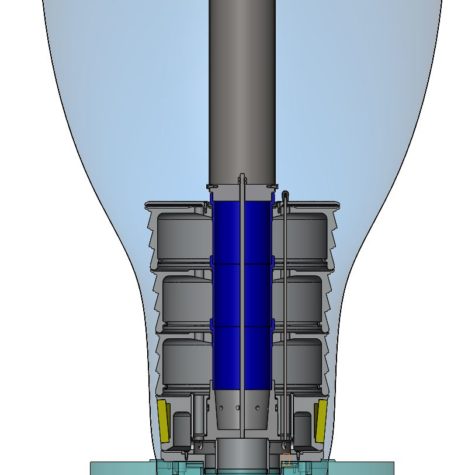

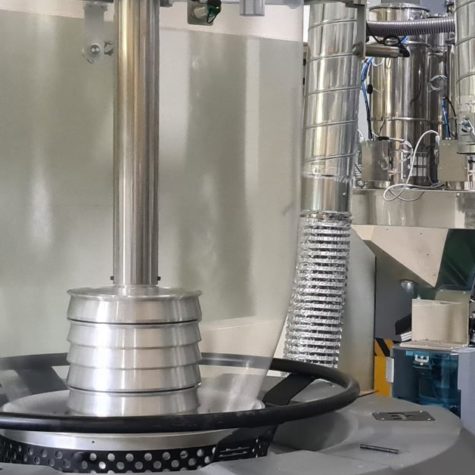

- COOLING BOOSTER SYSTEM TO MAXIMIZE THE STABILITY OF BUBBLE SHAPE

- HIGH QUALITY OF THE BASIC THICKNESS PROFILE

- 25% MORE IN OUTPUT THAN A STANDARD IBC

Vortyx

IBC cooling booster system

When developping the FLYER air rings and internal cooling devices VORTYX, SYncro was aiming for the “coexistence” of two elements that seems to be in perpetual conflict and incompatible between each others: turbulence and stability.

Every manufacturer’s goal is to build an equipment capable to maximise heat exchange which would lead in high throughput, bubble shape stability and guarantee high quality through thickness profile control to the set-point desired.

These are the key requirements which has driven SYNCRO to engineer its external and internal cooling devices (FLYER and VORTYX).

SYNCRO is always searching for air rings inserts most effective aerodynamic profiles and efficient internal bubble cooling systems. It is evident the legacy with recent SYNCRO’s proven quality in air ring design providing the carbon fiber and extremely high insulating chambers (double skin design), single air inlet to keep the attractive design together with its simple and clean line, double adjustment technology TECH 2.0 (flow and / or temperature) which is SYNCOR’s patent.