- MEASUREMENT FOR ALL SUBSTRATES AND PRODUCTIONS Easycoater measures adhesive in the range 0,1 - 10 g/ m2 along the layflat applied on all lamination supports: printed, metallized, transparent films and polyolefins, ensuring versatility access all production application.

- STABLE AND PRECISE Delivers extremely stable and precise measurement: down to 0,1 g/m2 of repeatability. Internal compensation of temperature and humidity in the scanning head guarantees accurate measurements under varying operating conditions.

- AUTOMATIC REGULATION The system manages automatic distribution control: physical (analog signal) or logical (OPC UA) signals are processed for optimal adjustment of the crossweb distribution of the applied adhesive.

- FAST SET UP Average commissioning time is less a matter of minutes, allowing for quick integration into the production process.

- EASY ACCESS FOR MAINTENANCE Easycoater has been designed to guarantee easy access during maintenance operations, while also ensuring long lifetime, with a rugged and robust frame.

- FREE MECHANICAL INSTALLATION Based on the backscattering principle, Easycoater does not require a second head on the other side of the film, thus allowing direct installation on a single side of the line. A simple reflective plate can be positioned under the film when it is not possible to measure directly above one of the existing rollers.

- INDUSTRY 5.0 & IoT All Syncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

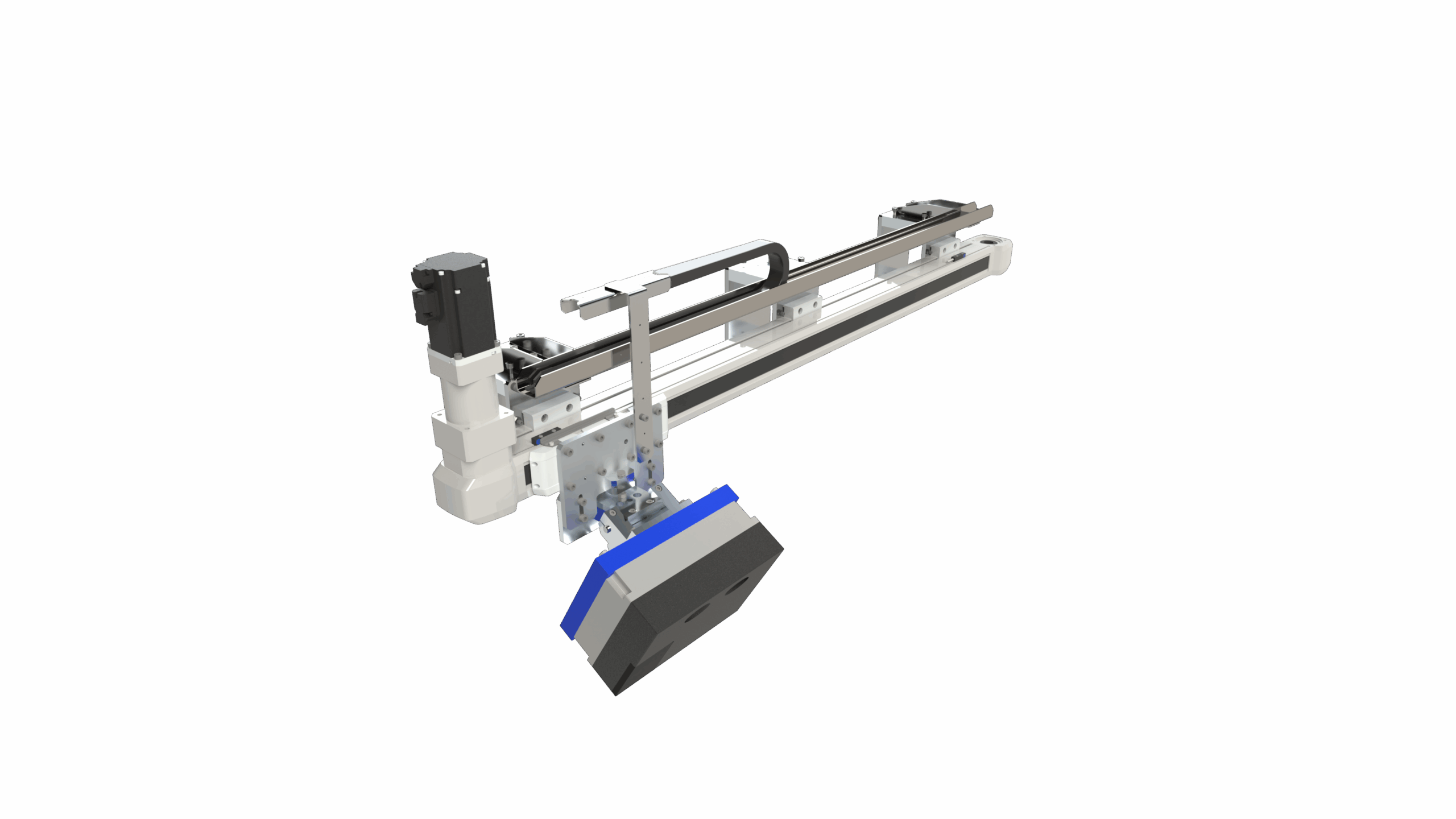

EASYCOATER

Adhesive layer measurement in lamination process

EASYCOATER is the new Syncro device for measuring the quantity and distribution of adhesive during the lamination process. Easycoater utilizes a reflection measurement configuration with easy and non-invasive mechanical installation. The non-contact IR head detects adhesive in the range 0,1 – 10 g/m2 along the entire layflat.

Processes: