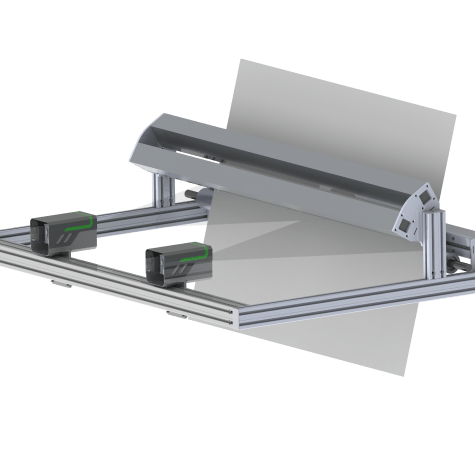

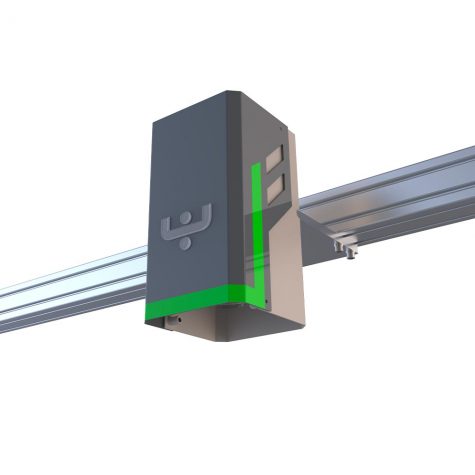

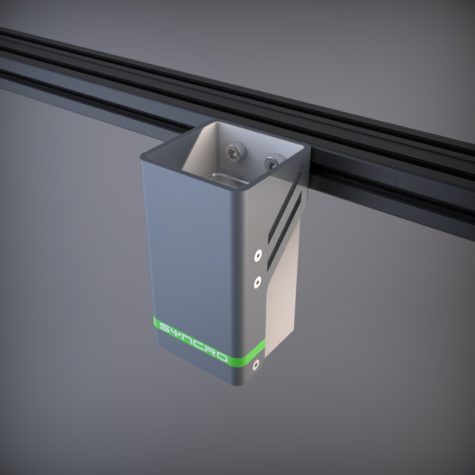

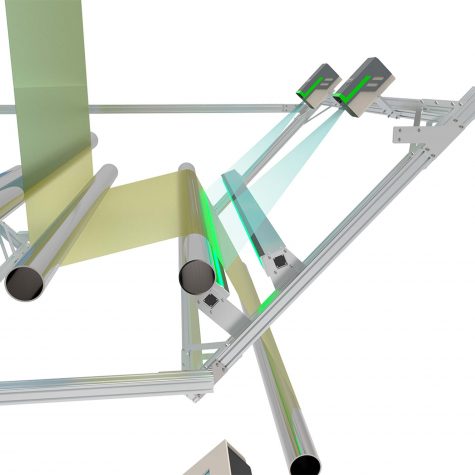

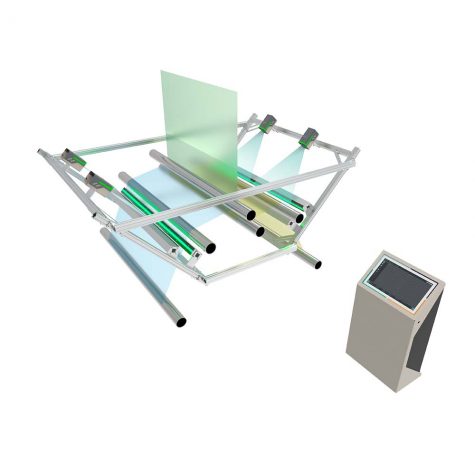

- HARDWARE MODULARITY - Multiple camera configurations are available depending on the size of the defects to be detected and the production speed. Thanks to the high resolution of the cameras and the computing power of the latest generation processors, EYes can detect defects down to 3 μm, imperceptible to the human eye, and can scan films travelling at speeds of up to 1200 m/min. In standard applications, a single backlight illuminator suffices to detect all common film defects. Two additional types of illuminators for specific needs: Incident illuminator is essential for dark material and thick film production. Reflection illuminator is useful for detecting coating defects.

- HMI & REPORT - Eyes features an intuitive HMI for real-time visualization of the inspection process, including advanced 2D mapping for defect analysis. It automatically catalogs defects and provides statistical analysis, enabling detailed inspection reports aligned with industry standards for enhanced productivity and waste reduction.

- FRAME SETUP - An intuitive HMI control panel helps to improve productivity, giving real-time process visualization with 2D mapping, this allows the operator to quickly view the quantity and density of any defect’s, plus their categorization and position. The system provide process statistical analysis with reporting capability simply from the click of a button.

- INDUSTRY 4.0 & IoT - All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Eyes

Customizable High performance

EYES is a vision system for in-line quality control of continuous materials. The system can scan 100% of the surface, detecting and classifying every type of defect. Eyes provides comprehensive defect mapping for each roll, allowing you to maintain complete control over your production. It is ideal for production lines exceeding 300 m/min speed and defect resolutions below 250 μm, down to 3 μm.

Eyes analyzes various processes like extrusion, coating, and laminating across a range of materials such as plastic, paper, glass, metal, rubber, and membranes. These materials exhibit diverse optical properties from transparency to opacity and glossiness. Lighting configurations are tailored to these properties and the specific defect types being detected.