- TREATMENT TIMES - The process involves 75 minutes of treatment for crystallization and pre-drying and another 75 minutes for vacuum dehumidification. The total time to obtain a crystallized and dehumidified R-PET is therefore 2 hours and 30 minutes against the 6-7 hours of a traditional system.

- VOLUMES - Given the treatment times reduced by at least half compared to a traditional system, the FYNISHER also involves an equally important reduction in volumes and therefore in the space on the ground of the equipment.

- ENERGY CONSUMPTION - Once the recycled PET has been actively heated in the first crystallization and pre-drying stage, the vacuum unit can use the heat already present in the material to operate the dehumidification. In terms of energy consumption, the savings are at least 40% compared to a traditional treatment system.

- COSTS OF MAINTENANCE AND OPERATION - The dehumidification is carried out with the action of the vacuum, whereby the humidity – but also the ethylene glycol and any other contaminants – are extracted from the recycled PET and evacuated towards the outside. Therefore, unlike a traditional system, the work circuit is “open”: there are no molecular sieves or condensing units, i.e. there are no parts of the system that degrade and require a production shutdown for their maintenance / cleaning . In this way, the FYNISHER manages to reduce maintenance costs and ensure continuous operation.

- INDUSTRY 4.0 & IoT - All SB DRY machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

SYNCRO GROUP

Ideal partner for plastics processors who require innovative technology to gain a competitive edge.

Finysher

A new approach to Recycled PET

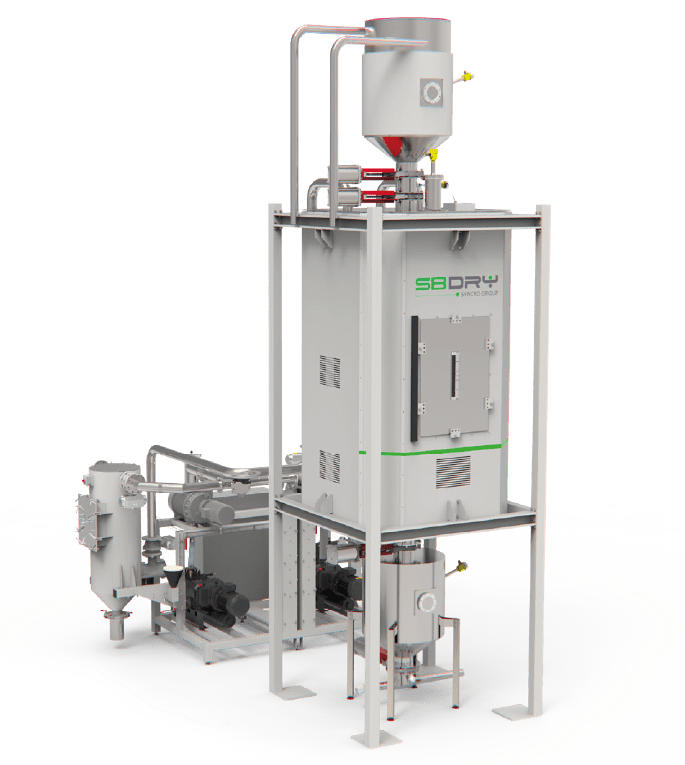

Crystallization and high dehumidification dedicated to the treatment of large productions of recycled PET (R-PET) from 500 to 2.500 Kg/h.

The FYNISHER combines a crystallization phase with hot air with a dehumidification phase under vacuum. Using hot air and slow mixing, the recycled PET is first crystallized and pre-dried. Subsequently, the hot material is transferred to a vacuum unit in which the residual moisture is extracted up to values < 30 ppm. Together with the humidity, the “stripping” action of the vacuum also allows to extract the ethylene glycol and any other contaminants present in the recycled PET. The process takes place continuously and has been specifically designed for productions exceeding 500 kg/h.