- EASY INSTALLATION - Syibc can be easily installed on existing Blown Film Lines.

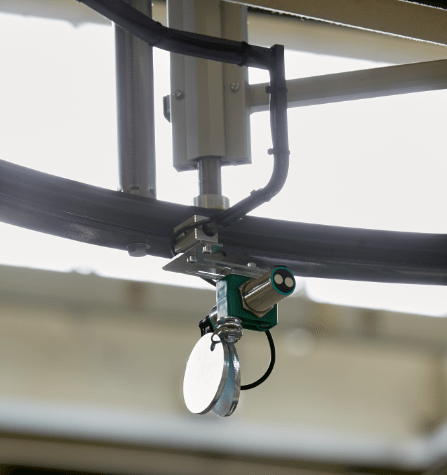

- OPTION LAY FLAT CONTROL - As an option, Syibc can control the lay flat width in full AUTO mode, acting on the bubble cage diameter and keeping the lay flat set point within a < ± 2 mm tolerance. With the LAY FLAT CONTROL option, Syibc uses 4 LAY FLAT sensors in order to keep a perfect 90° angle, additionally a potentiometer is also installed in order to detect the bubble cage diameter.

- GAP SENSORS - Syibc uses 3 GAP sensors when the cage has 6 or 9 arms and 4 sensors when the cage has 8 or 12 arms in order to keep a perfect angle between them.

- AMBIENT TEMPERATURE COMPENSATION SENSOR - With the LAY FLAT CONTROL option, Syibc uses 1 temperature compensation sensor in order to calibrate all the sensors when the ambient temperature has a variation.

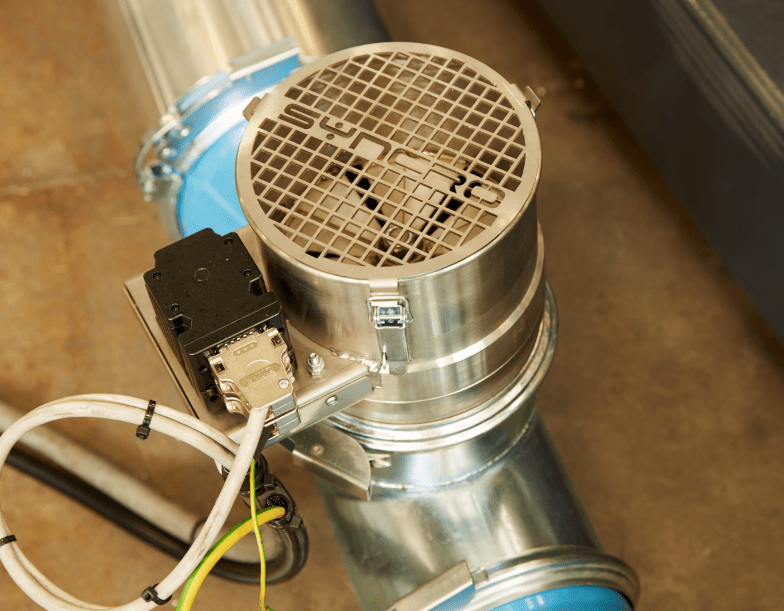

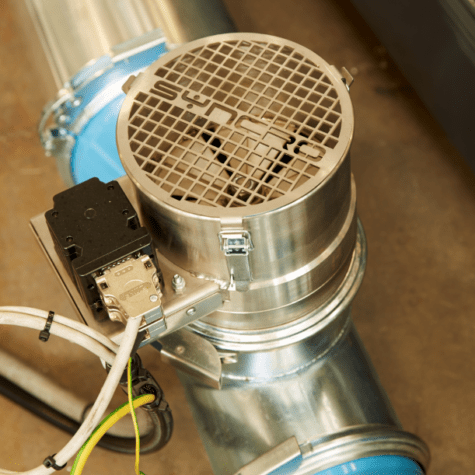

- FINE TUNING VALVE - Syibc has an IBC valve equipped with a stepper motor with a 7000 step function for precise and accurate regulation.

- OEM or BOX VERSION - Syibc can be supplied in a stand alone BOX or wired on a panel integrated in the SYNTROL cabinet or OEM cabinet.

- INDUSTRY 4.0 & IOT - The Syibc control cabinet is equipped with PLC & PC ready OPC-UA protocol for industry 4.0.

Syibc

IBC control System

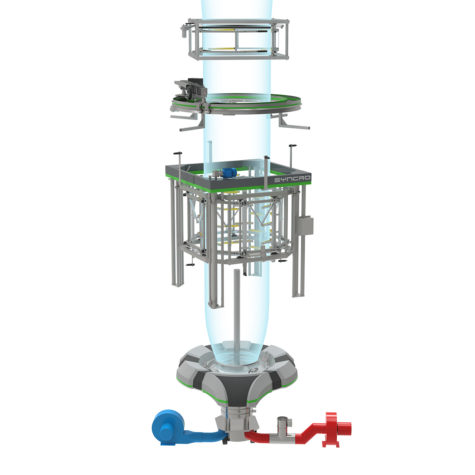

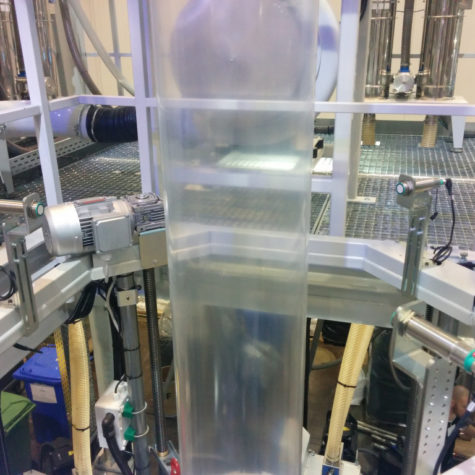

SYIBC is SYNCRO’s full IBC control system designed to manage and control several components in the Blown Film line for set up and control of the lay flat of the film, the system can be installed standalone or fully integrated.

SYIBC guarantees to maintain the width set point of the film, controlling the blowers ratio, valve and bubble cage.

Syibc is connected to 4 Ultrasonic Sensors located on the Bubble Cage Arms to manage the gap set up and 4 Ultrasonic Sensors located on the top part of the Bubble Cage to measure and manage the lay flat width.

In order to maintain the gap set up, Syibc controls both the IBC blower inverters and IBC valve, modifying blower RPM and IBC valve position.

When equipped with the LAY FLAT CONTROL OPTION, Syibc also controls the Bubble Cage diameter.