- GREAT ACCURACY & CONTINUOUS ACTION SYdos continuously measures the flow rate of each material, so that any variation is registered instantly and the machine immediately regulates all the dosing in order to keep the specified setpoint. Since the flow rates of the individual components and the extruder’s are known, their cross-comparing allows to identify irregularities and achieve better dosing accuracy. The solid structure works as a filter for the effects of the vibrations, so that no noise is introduced in the load cells’ measurements.

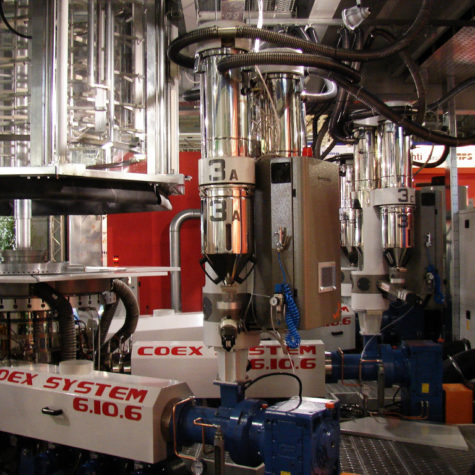

- EXTENDED RANGE AND MODULARITY SYdos has a flexible choice of machine sizes and dosing screws in order to cover a wide range of flow rates and material granulometries, from the lowest rates of additives in the small lines to the highest rates of main components in the big lines. Thanks to its modularity, it can also be easily configured in up to 5 secondaty components with an on-board cabinet that allows fast installation.

- EASY CLEANING & MAINTENANCE Thanks to its removable hoppers and screws, SYdos allows for an easy cleaning and changeover process.

- OPTIONALS There are different optionals available in order to satisfy every need: components and kits for dosing high-temperature materials, and a centralized conveying system controlled by the machine itself.

- INDUSTRY 4.0 & IoT All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Sydos

The continuous loss-in-weight gravimetric Blender

SYDOS is a continuous loss in weight gravimetric dosing system designed to meter multiple components simultaneously and is ideal for different production processes where accurate and consistent blends are required.

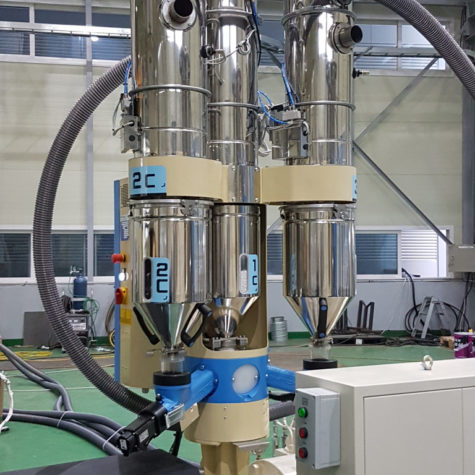

All the side components are continuously and simultaneously metered directly in the extruder feed throat through a cascade mixer.

Each of the side components are simultaneously metered into a cascade mixer where they are blended together with the main gravity flowing component.

The side feeders are individually controlled in order to reach and maintain the preset metering ratios and to maintain a constant level above the extruder feed throat.