- GREAT ACCURACY & CONTINUOUS CONTROL SYSTEM ModYx continuously measures the dosing rate of the each secondary component, so that any variation is recorded and compensated for. The primary component can end up passively in the extruder or be weighted too in order to achieve greater precision and control.

- LOW THROUGHPUTS Specially designed augers for dosing at very low rates are available.

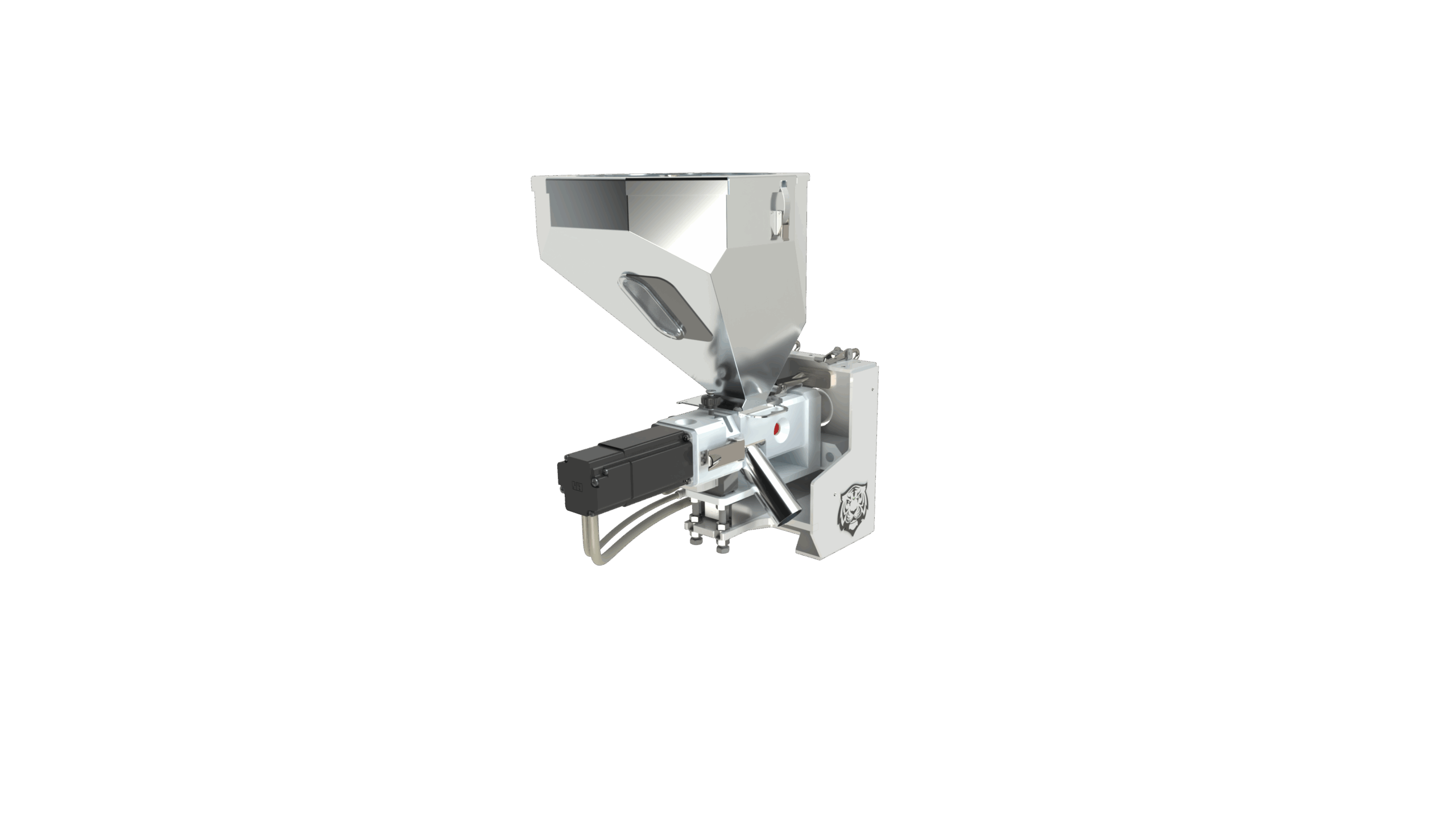

- STRUCTURAL RIGIDITY The solid structure of the body acts as a vibration filter so as not to introduce noise into the load cell readings.

- EXTENDED RANGE AND MODULARITY ModYx uses a wide range of dosing screws to cover a variety of material flow rates and granulometry, from low percentage additives as well as secondary components with a higher percentage in the recipe.

- MULTI-COMPONENT STATION ModYx can be customised with one to four subcomponents, plus the main component.

- EASY-ACCESS Installation and easy access are strengths of the design, making cleaning and maintenance extremely fast and intuitive.

- LOADING AND TRANSPORT Modyx is capable of loading and conveying management as an integrated logic function.

- REMOTING FOR INJECTION The HMI and control panel can be remotecontrolled for installation on molding machines.

- INDUSTRY 5.0 & IoT All Syncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Modyx

Continuous loss-in-weight feeder

MODYX, continuous loss-in-weight dosing system designed to ensure gravimetric feeding of a recipe in processes requiring low throughputs and high accuracy. It guarantees the ratio between components in the recipe, respects and controls dosing accuracy and the total throughput of the extruder or press. ModYx is ideal for injection molding, blown molding and extrusion lines.