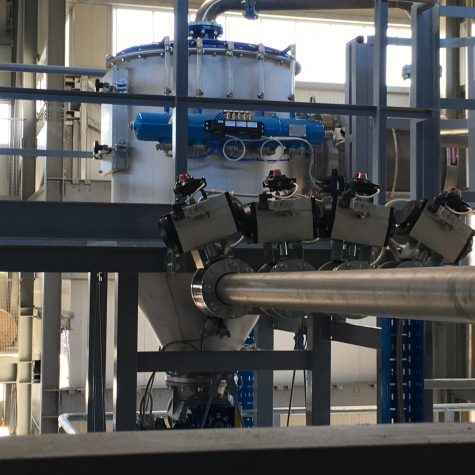

- DIFFERENT FILTERS - According to the kind of product to be conveyed, the HL receiver can be equipped with sleeve type or cartridge type filters of different materials. The type of filter chosen is according to the product to be conveyed and to the feed rate of the line.

- SELF CLEANING SYSTEM - The HL receiver is equipped with a compressed air tank and cleaning valves, during the conveying cycle compressed air is injected in the inner part of the filter to keep it clean. The cleaning cycles, as well as the intensity of the cleaning airflow can be controlled via the PLC or by an electronic card.

- EASY MAINTANANCE OPERATION - During line maintenance operations the HL receiver can be easily dismantled through a front door or via clamps without the need for tools.

- DIFFERENT HOPPER CAPACITY - The modularity of the HL receiver allows it to be used for different discharge hopper capacities ranging from 15L up to 600L.

- EXTRACTION SYSTEMS - When the product is not free flowing, the HL receiver can be supplied with various flow aids such as fluidization nozzles and pneumatic or electro pneumatic vibrators.

- INSTALLATIONS - The receiver HL is always supplied pre wired with junction boxes to permit an easy and fast installation.

- WEIGHING SYSTEM - If required, the HL receiver HL can be installed with load cells for the weighing of the material, a standard kit is available for all sizes.

- CONTROL SYSTEM AND INDUSTRY 4.0 - The conveying control system can manage from a single receiver up to several receivers and production lines. The PLC is supplied with OPC/UA protocol embedded, which make each machine modular and ready for industry 4.0.

- HMI - The conveying control system is equipped with a user friendly HMI touch screen (7”-9”-15”).

- OPTIONS AVAILABLE - As an option the HL receiver can be designed for high temperatures, ATEX compliant and/or FDA compliant

PLANTECH-CST

Always deliver more than expected

HL – Hopper loader for powders

RECEIVERS FOR POWDERS - HL

The hopper loader series HL is Plantech-CST’s receiver for powdery or dusty bulk materials. This equipment can be used in stand alone or centralized conveying systems both in pressure and vacuum situations. The wide range of sizes allows for conveying from 1Kg/h up to 4000 Kg/h.

The product picked up from a storage device through a suction probe/screw/rotary valve is pneumatically conveyed either via vacuum or pressure by means of a conveying pump. The product is transferred to the HL receivers. During this phase the integrated filters are cleaned through the pulsation of compressed air, when the cycle is completed the product is discharged from a butterfly valve installed on the bottom of the receivers.