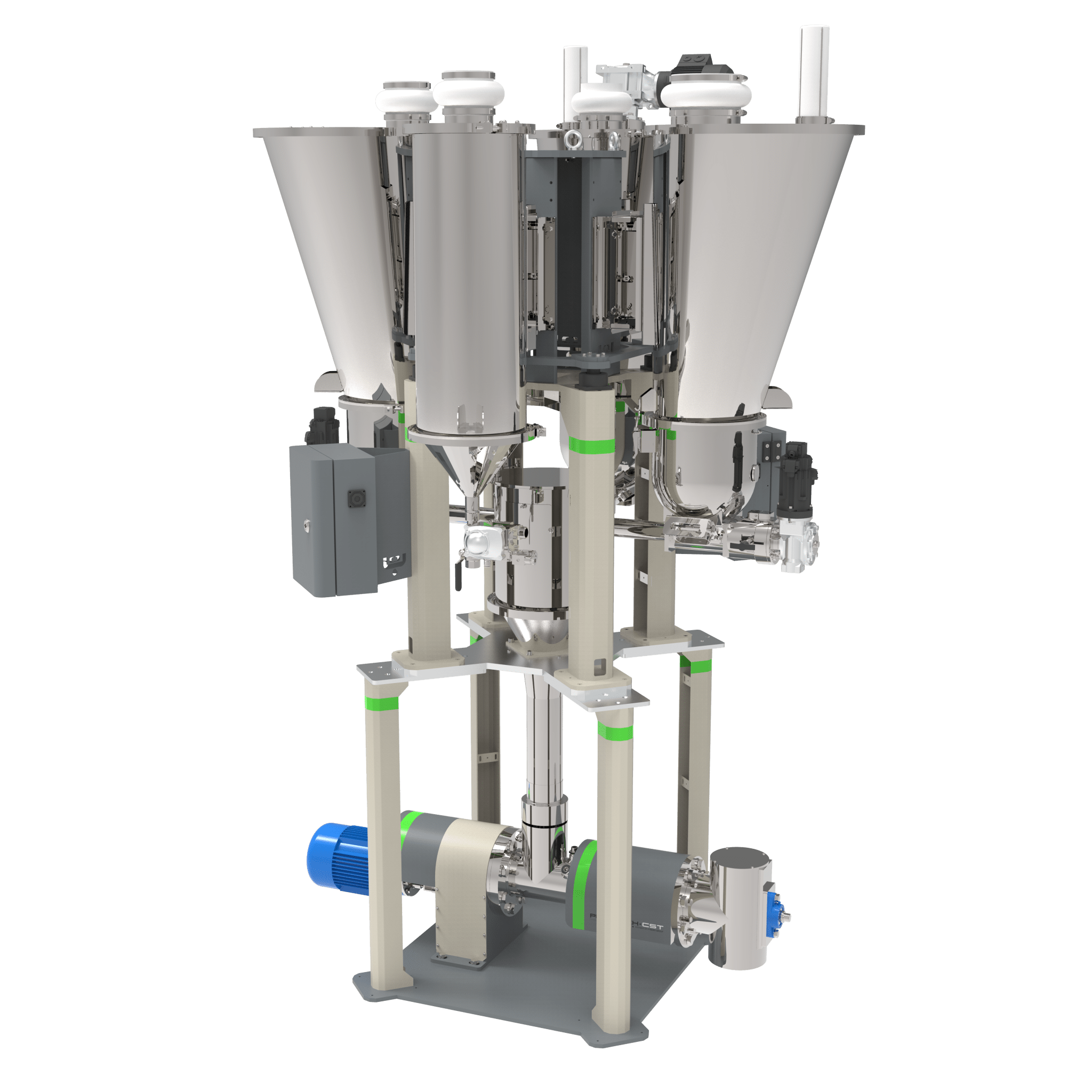

- HIGH PERFORMANCE C-DYNAMIX - guarantees a high accuracy in feeding (+/- 5%) in a range of 1:10. It can be designed in various sizes from 100 to 1000 kg/h

- MODULARITY - Thanks to its modular design C-DYNAMIX in its various version can feed up to 6 solid and 3 liquid components.

- HMI - The C-DYNAMIX control system is equipped with a user friendly HMI touch screen (7”-9”-15”).

- PLC & INDUSTRY 4.0 - C-DYNAMIX has a PLC with UPC/UA protocol embedded. This solution makes each machine modular and ready for industry 4.0.

- EXTRUDER INTERFACE - C-DYNAMIX is supplied with an extruder interface complete with 2 level sensors to control the extrusion throughput.

- OPTIONS AVAILABLE - As an option, C-DYNAMIX can be supplied ATEX compliant and in a dust proof design.

- BENEFITS: - High dispersion - Constant crosslinking - High repeatability - Recipe changes on the fly - No calibration required in case of products changes - Raw material savings from 5 to 10% - Fast ROI - Reduced amount of waste - Fast start-up operation - Compact design - Low consumption of Nitrogen - Possibility to install the equipment on new or existing extruders

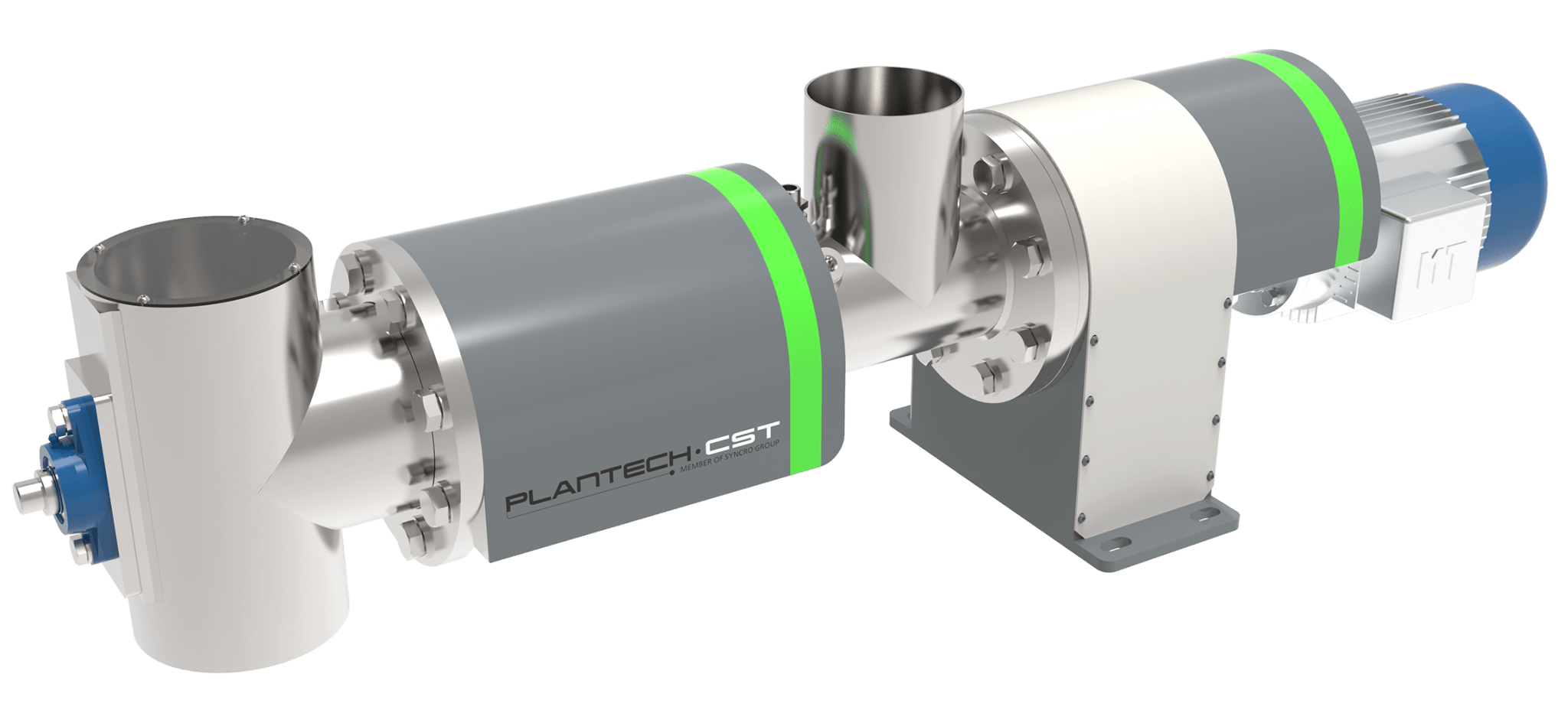

C-DYNAMIX

MULTI COMPONENT FEEDING AND BLENDING STATION FOR SOLID AND LIQUID COMPONENTS.

PLANTECH-CST dosing and blending station C-DYNAMIX is a modular multi component continuous gravimetric feeding and blending station. The dosing station can be completely customized on the basis of customer recipe and process. Different dosing units, for solid or liquid components can be combined and feed the products in a continuous mixer. The system can be supplied as a complete system for the conveying system of powders and liquids.