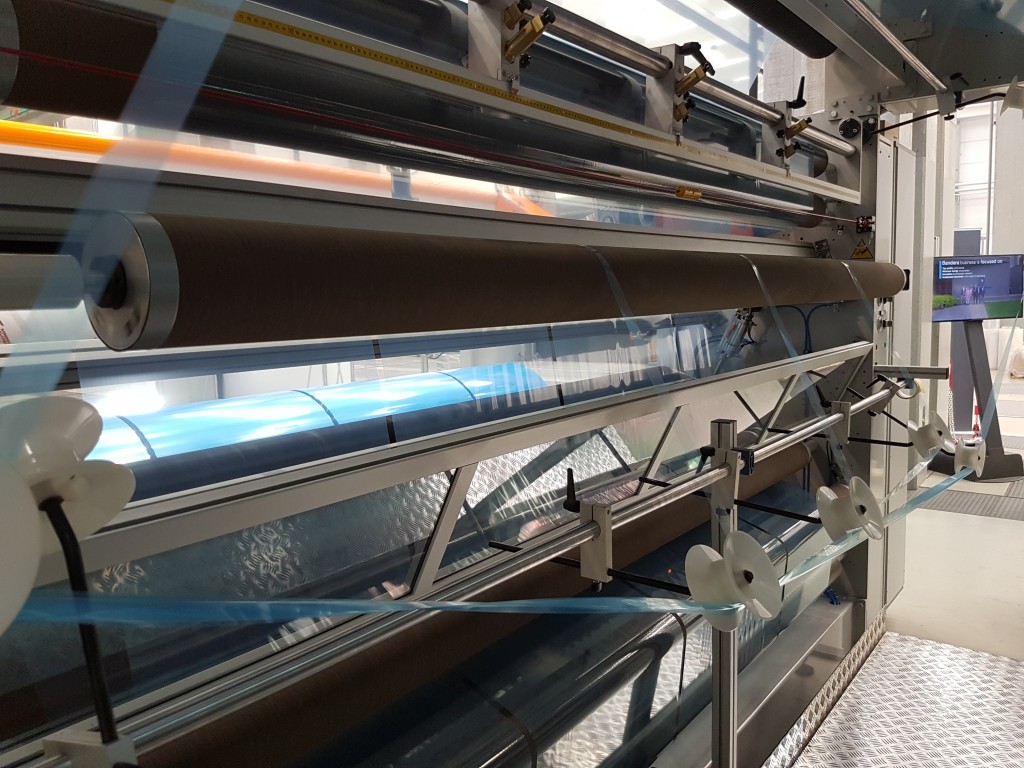

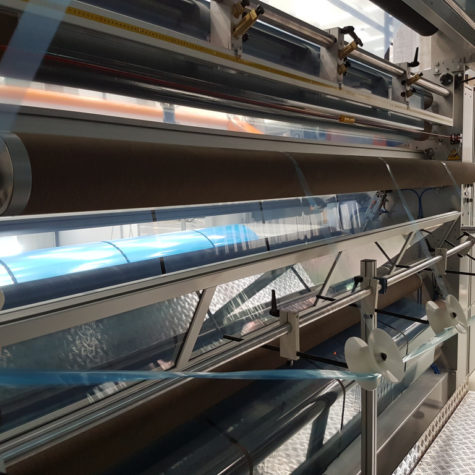

- Low noise and low power consumption. Comes complete with variable speed control of the blower to tailor the air flow

- Variety of sizes to suit all applications and needs

- Fully customisable configuration to meet all producers needs.

- Fully turnkey solution when coupled with a Plasmac Extruder

- Fully integrated solution that ensures the trims arrive at the extruder in a perfect condition to repelletis

- Delivers trims with minimal exhaust air.

- Can convey all types of trims from standard trims, tacky trims, trims with PIB up to high speed trims.

- A turnkey solution meaning Plasmac takes care of both your trim conveying and repelletising requirements. Meaning one point of responsibility.

- Trims are delivered with the minimum of air exhaust. Meaning there are no hang-ups, or balling of the trims causing bridging in the extruder, ensures the maximum uptime of your repelletiser.

- Low noise and low power consumption, allows you to install the blower within your production hall. The results in the easiest installation and low power consumption ensures power savings and the best return on your investment

- A simple, rugged design that just works. It means your operators can concentrate on running the extrusion line and not on handling trims.

PLASMAC

the best recycling solution to suit every customer's requirements

Powerfeed

The next generation of pneumatic trim conveying systems

Minimal power consumption & the highest output / kW installed power in the market – gives you lower runningcosts so improves your return on investment.