- WEIGHT-LOSS SYSTEM MYblend3 is the only continuous dosing system that does not suffer from the effects of volumetric irregularities in the loss-in-weight hopper filling phase.

- CERTIFIED SELF-DIAGNOSIS The hourly flow rate is calculated independently of the batch and loss-in-weight systems and must coincide: gravimetric dosing for sure! Otherwise the error is immediately reported.

- ACCURACY AT LOW % The patented MYblend3 technology can achieve minimum dosing rates of 50 g/h.

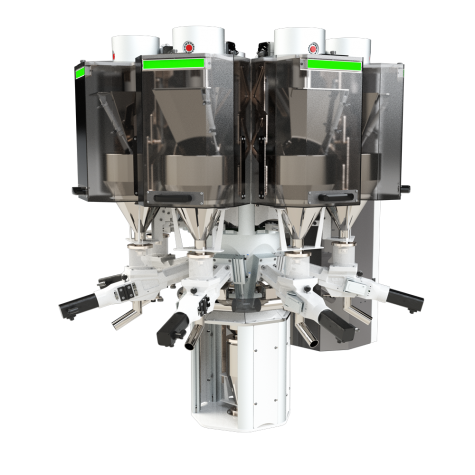

- 100% TECHNOLOGY Each component of MYblend3 is metered via a dedicated screw including the main material ensuring excellent extrusion flow control.

- MODULARITY The configuration is modular, the feeder can expand up to 6 components.

- TRANSPORT SYSTEM MYblend3 can be supplied together with the Syncro centralised transport system integrated in the same PLC as the feeder.

- BLENDING The static cascade mixer ensures homogeneous dispersion of all dosed components regardless of particle size and density.

- CLEANING All gravimetric hoppers are easily removable, ensuring fast and efficient cleaning and production changes. With the SMARTDRAYN option, material changeover occurs automatically without the need for a dedicated operator, allowing traceability of the drained component.

- HIGH TEMPERATURE OPTION On request, the MYblend3 feeder can dose hot components up to 180°C.

- POWDER ADDITIVE As an option, twin-screw dosing units can be installed on the MYblend3 feeder, allowing powder components of up to 5% to be added to the mixture.

- INDUSTRY 4.0 & IoT All SYncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.