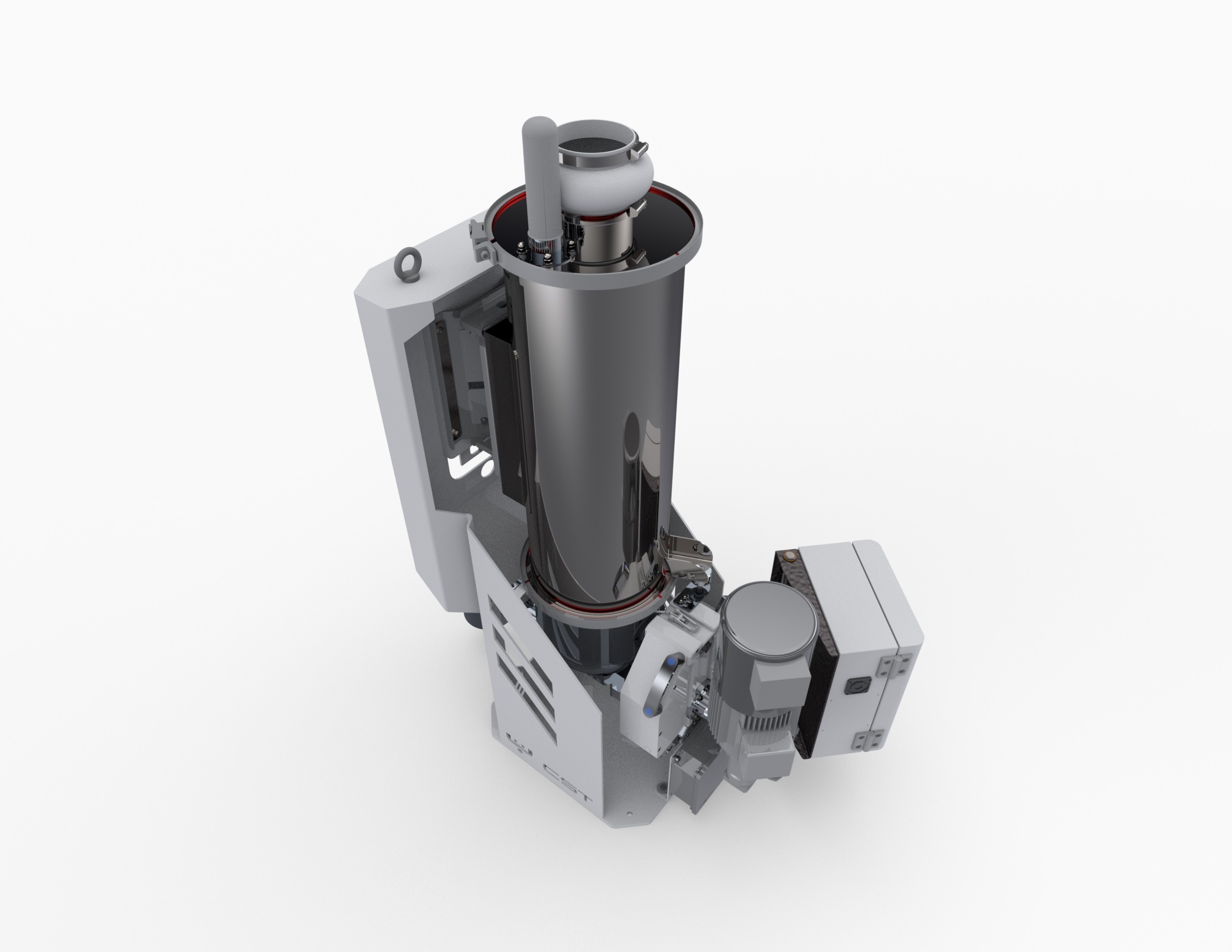

- HIGH PERFORMANCE - C-TWYN can guarantee a high accuracy in feeding (+/- 0.5%) in a range of 1:10.

- WIDE RANGE OF MODELS - The wide range of different dosing units allows the user to feed from 1 to 10800 dm3/h.

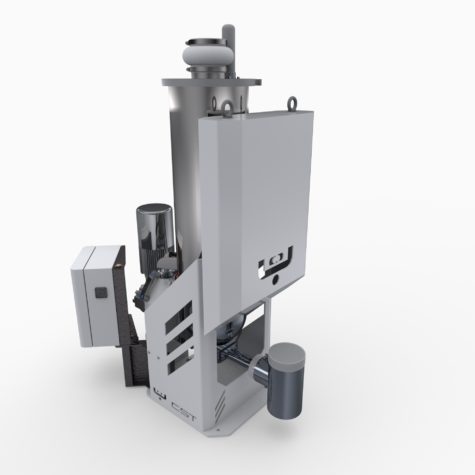

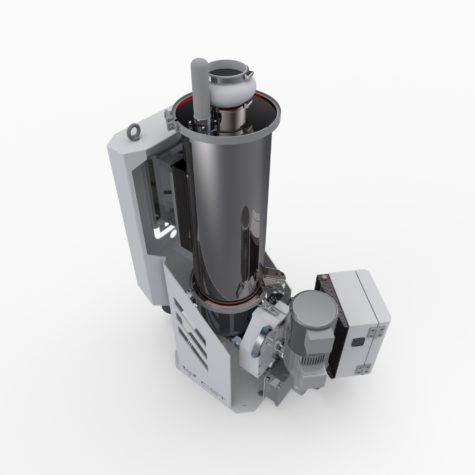

- MODULAR DESIGN - The design allows the possibility to change material and feed-rate by simply changing the screw and discharge outlet.

- MODULAR HOPPERS - Various shapes and sizes of standard hoppers can be perfectly combined with various measuring extensions chosen in relation to flow rate, in order to meet different dosing needs

- WEIGHING SYSTEM - C-TWYN gravimetric units can be installed on a platform scale or in a special designed scale frame to keep the equipment more compact. Analog load cell features: Resolution: 1:8388608 (± 23 bit) Accuracy: ± 0.03%

- INSTALLATION - C-TWYN is always supplied prewired with junction boxes to permit an easy and fast installation. C-TWYN feeders can be installed in a standalone frame or in a modular multi component dosing station frame C-MULTY which is available in various configurations: DS-4, DS-6 and DS-8, from 2 to 8 feeding units.

- CONTROL SYSTEM & INDUSTRY 4.0 - Feeder control system can manage from a single feeder up to several feeders and production lines. The PLC is supplied with OPC/UA protocol embedded, which make each machine modular and ready for industry 4.0.

- HMI - The feeding control system is equipped with a user friendly HMI touch screen (7”-9”-15”).

- OPTIONS AVAILABLE - As an option, C-TWYN can be equipped with a vertical agitator, designed for high temperatures, ATEX compliant and/or FDA compliant.

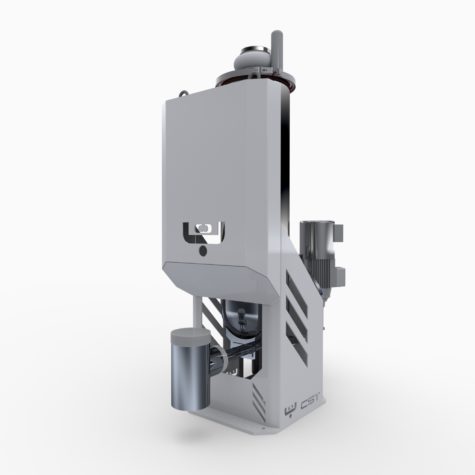

C-TWYN

TWIN SCREW FEEDING UNIT

C-TWYN is a twinscrew feeding unit engineered in different sizes in order to feed powders, granules, pellets, flakes and fibers and is available in volumetric or gravimetric versions. In the loss-in-weight modules, an analogue load cell is installed to guarantee a high weighing accuracy.

One single motor through an integrated gear box, drives the feeding screw and the horizontal agitator which avoids bridging and keeps a constant material flow. Different screw configurations allows the user to feed any kind of product with any kind of throughput accurately and with consistency.