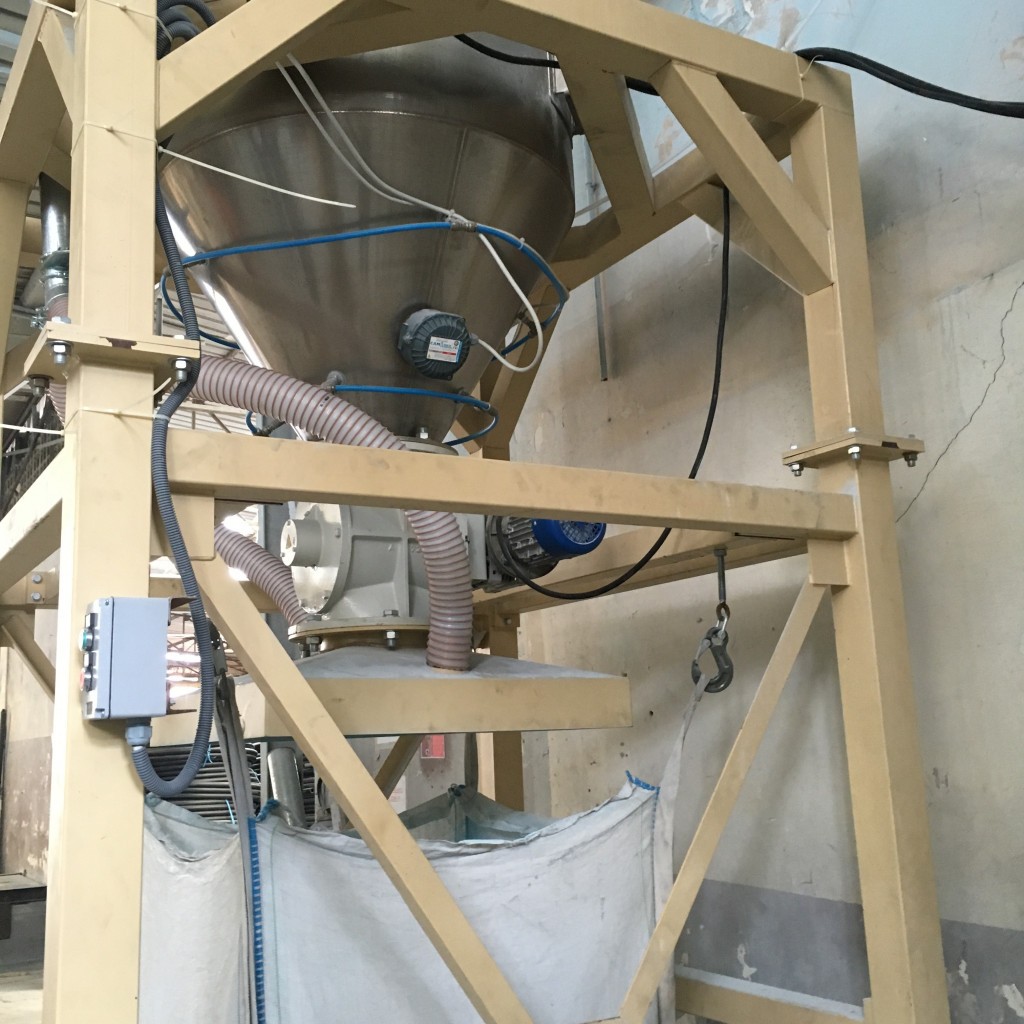

- MODULAR HEIGHT - The adjustable height of the frame allows it to adapt to different sizes of big-bags.

- TENSIONING SYSTEM - In order to completely fill the big-bag, the FBB filling big-bag station can be equipped with an automatic system managed by pneumatic pistons to tighten the chains and allow complete filling.

- DUST TIGHT LOCKING SYSTEM - When the product being handled is very dusty, a pneumatic sealing system can be installed at the inlet of the big-bag to prevent dust leakages in to the environment.

- DE-DUSTING CONNECTION - The filling sleeve can be equipped with an internal double chamber to be connected to a de-dusting suction system.

- WEIGHING SYSTEM - If required, the FBB filling big-bag station can be installed with load cells for the weighing of the material.

- INSTALLATIONS - The filling big-bag station FBB is always supplied pre-assembled and prewired with junction boxes to permit an easy and fast installation.

- OPTIONS AVAILABLE - As an option, the empty big-bag station DBB-P can be designed ATEX compliant and/or FDA compliant.

FBB – Big Bags filling stations

Filling big-bag station

The FBB filling big-bag station series is Plantech-CST’s modular solution to automatically fill big-bags and to allow their fast removal and replacement by a forklift or a manual pallet truck.

The big-bag is hooked on the station via adjustable chains and fixed to the big bag inlet probe, when the filling is completed the operator can remove the filled big-bag. The modular FBB filling big-bag station can handle a variety of different sizes of big-bags.