- MODULAR DISCHARGE HOPPERS - Installed below the discharging grid is a hopper with a design based on the flowability of the product being emptied - Standard hopper for free flowing products - Flat bottomed hopper with incorporated agitator - Hopper with bin activator - Hopper with fluidization nozzles and pneumatic or electro-pneumatic vibrator

- BIG-BAG UNLOADING - If required, the empty bag station EB can be equipped with a connection to discharge big bags also.

- WEIGHING SYSTEM - If required, the empty bag station EB can be installed with load cells for the weighing of the material.

- INSTALLATIONS - The empty bag station EB is always supplied pre-assembled and prewired with junction boxes (when electrical device are installed) to allow for an easy and fast installation.

- OPTIONS AVAILABLE - As an option, the empty bag station EB can be designed ATEX compliant and/or FDA compliant.

EB – Manual empty bag

MANUAL EMPTY BAG

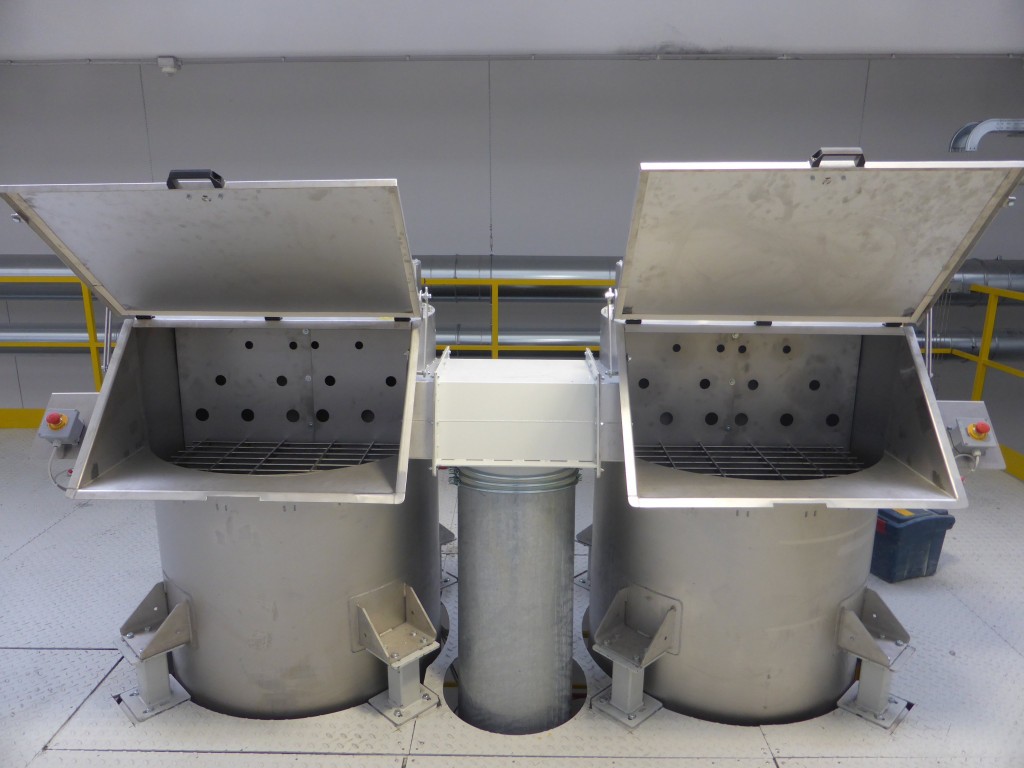

The manual empty bag station series EB is Plantech-CST’s modular solution to open and discharge bags.

The discharge station can handle various sizes of bags containing free flowing and poor flowing products using the appropriate discharge hopper and flow aid.

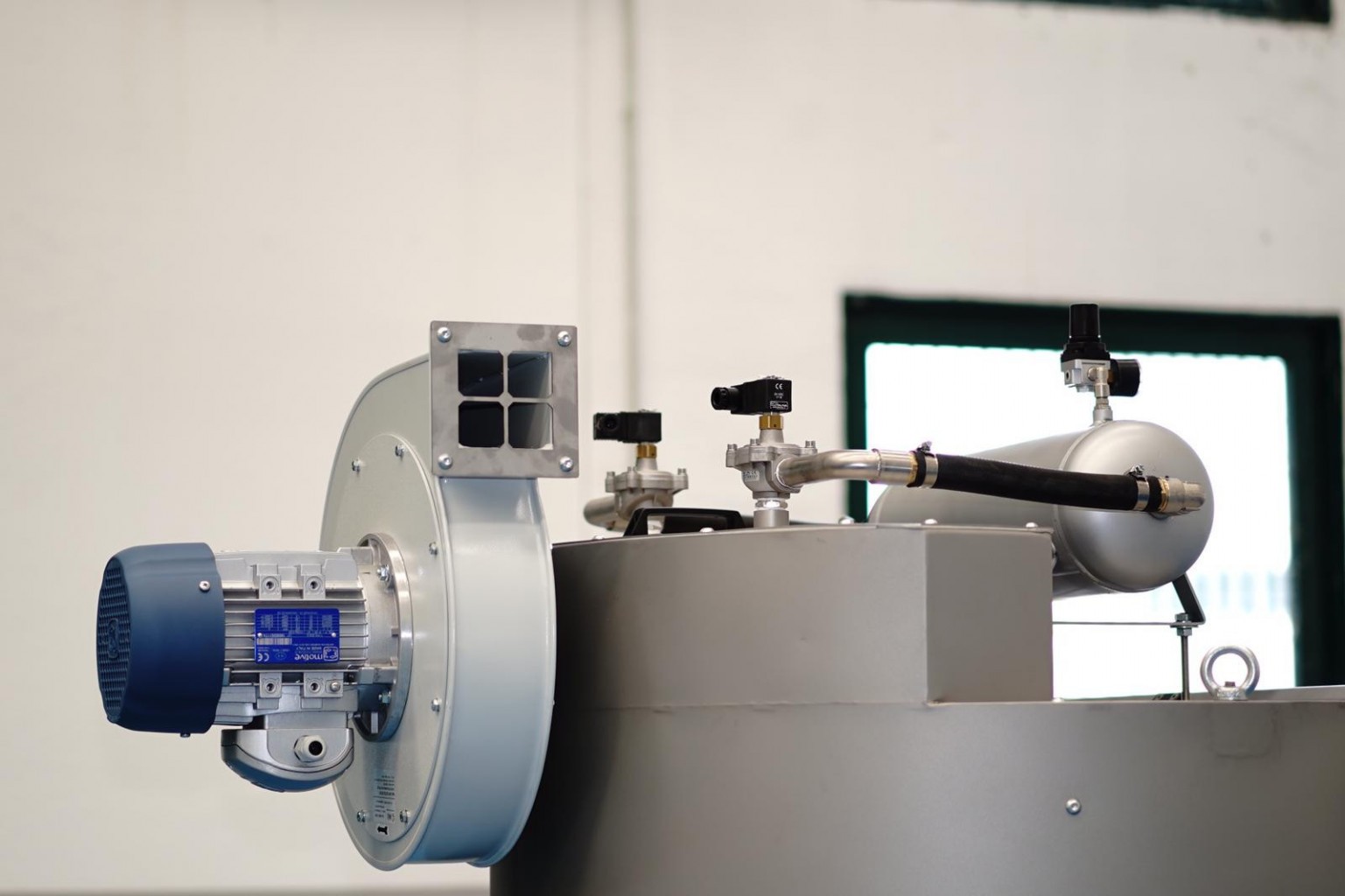

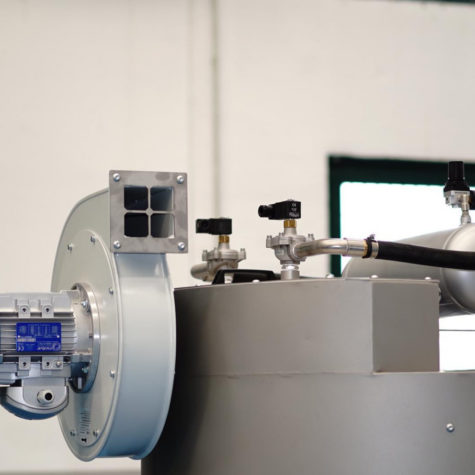

The empty bag station series is ergonomically designed with a wide feeding door. After opening the sealed door, the bag is manually opened on a grid while a fan and filter system remove the dust to avoid leakages into the external area. The dust on the filter is discharged back into the hopper when the door is closed through a compressed air pulsation system. For non-dusty materials the filter and fan unit is not installed.