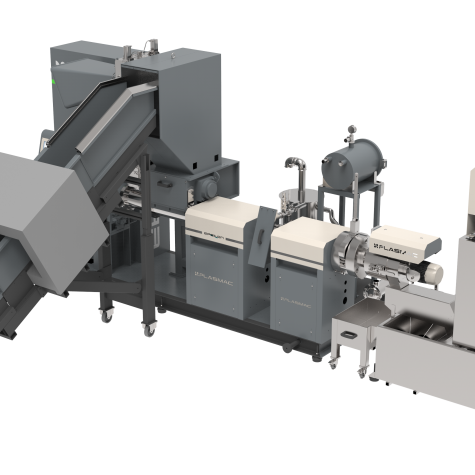

- Minimal power consumption & the highest output / kW of installed power in the market. Giving you lower running cost and therefore the quickest return your on investment with paybacks in as little as six months

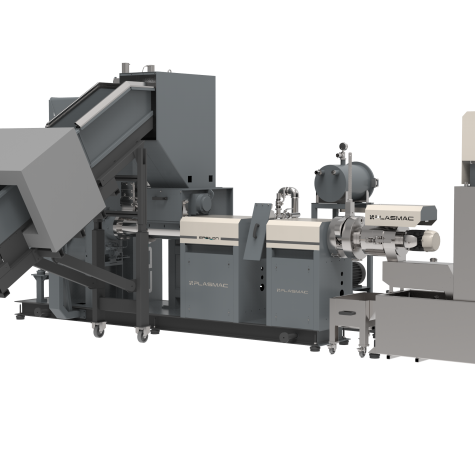

- Low shear, minimum process dwell time and the absolute minimum of material degradation. Means you can recycle all of your scrap material into high quality pellets, reducing your material costs and improving your profitability

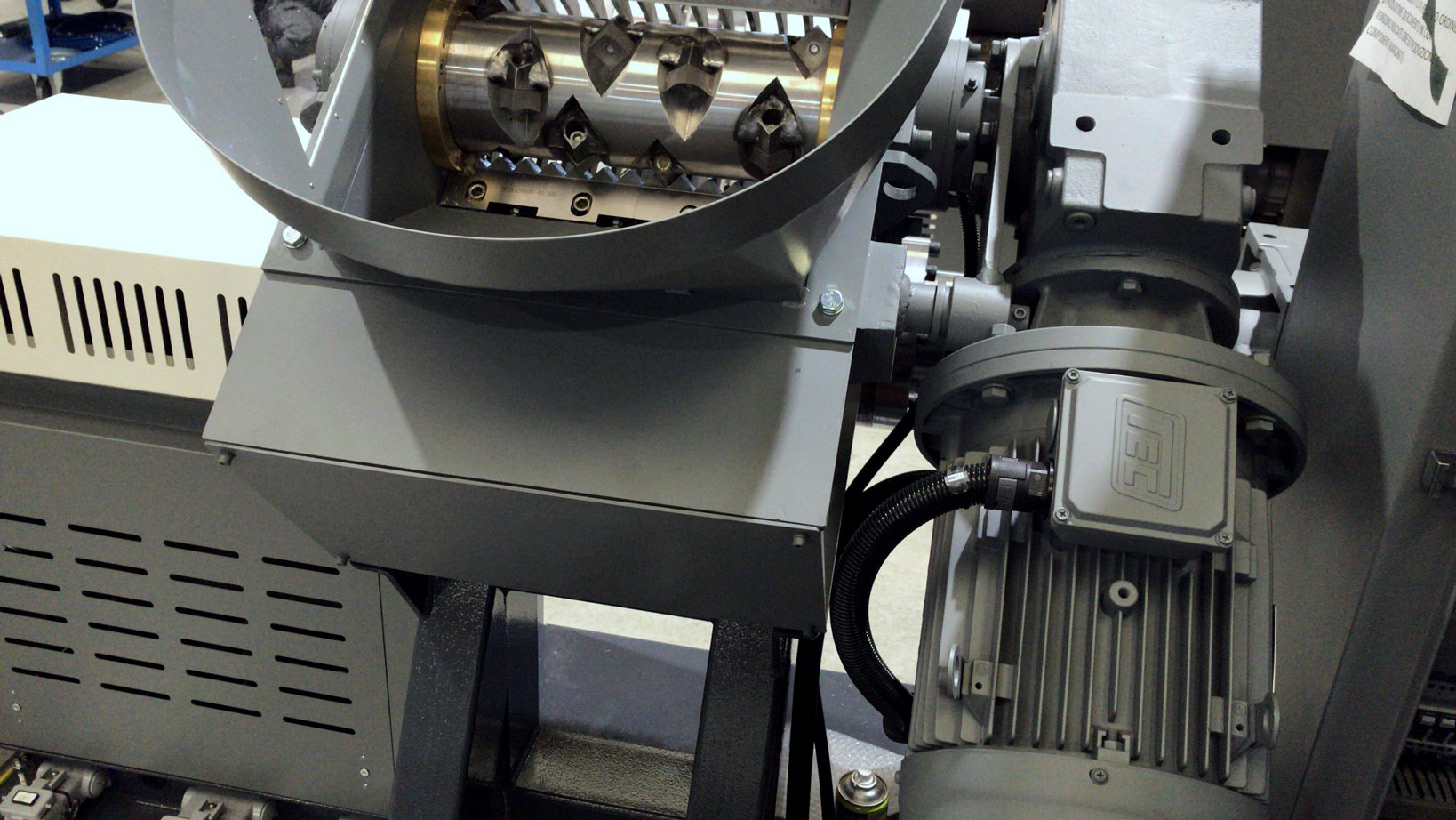

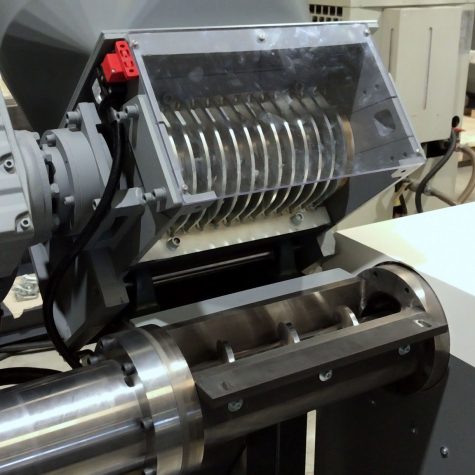

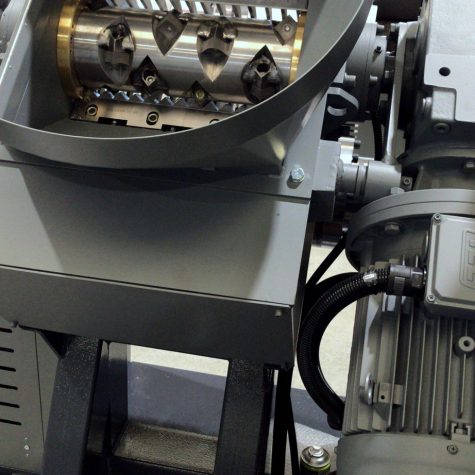

- Slow rotating inline shredder technology and unique feed hopper design. Requires no cooling water of the rotor, reduces maintenance and costs, therefore improving your profitability

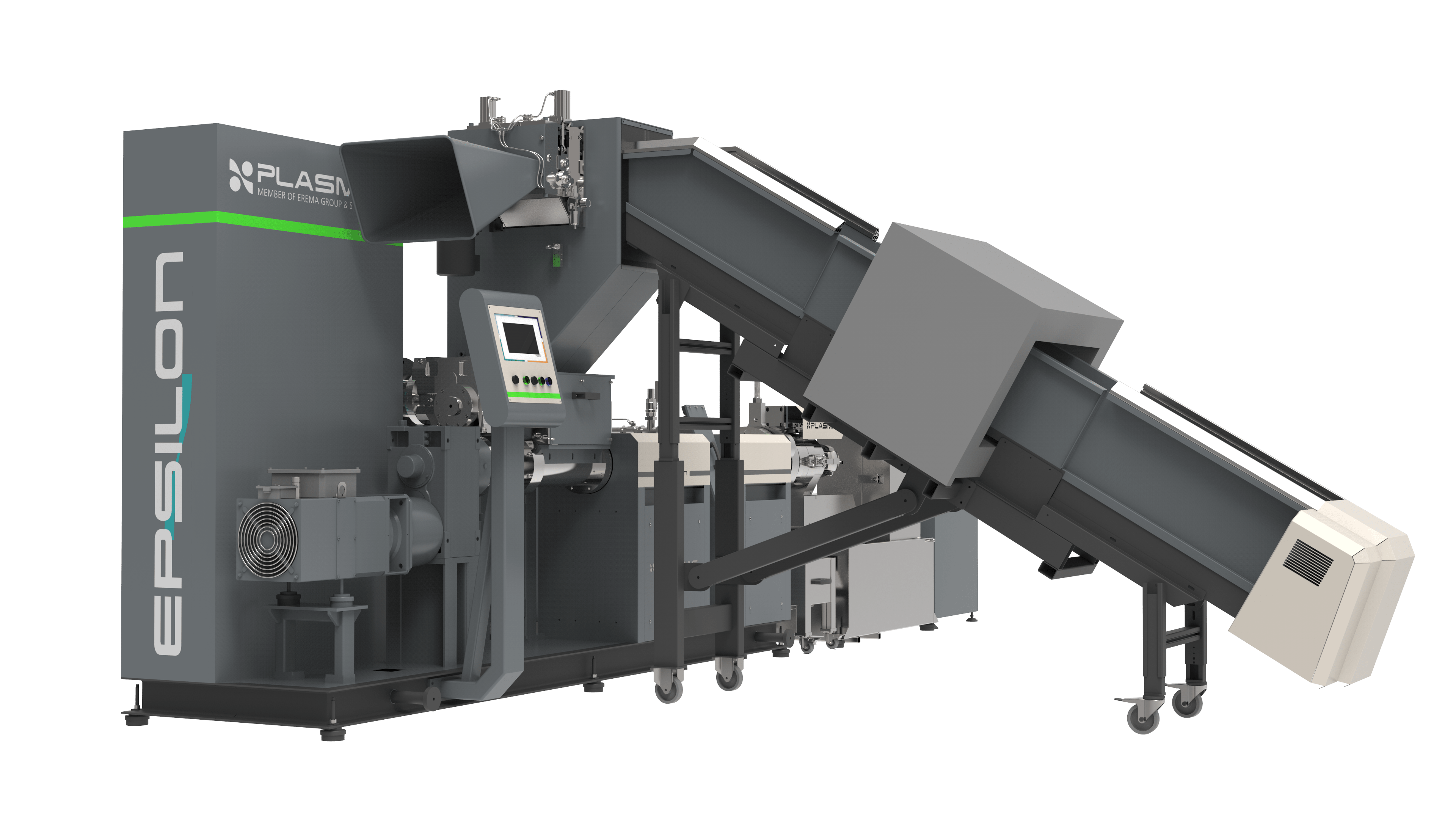

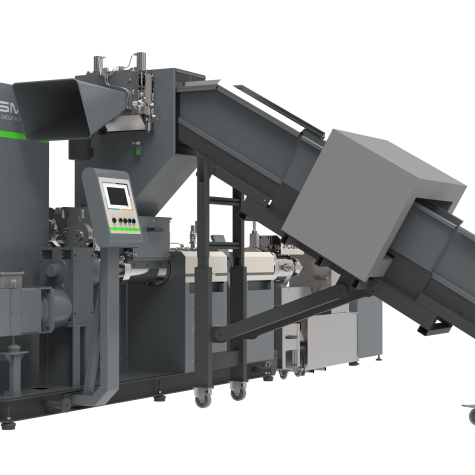

- Smallest footprint recycling machine available on the market. Minimal floor space is required freeing up valuable floor space for other applications

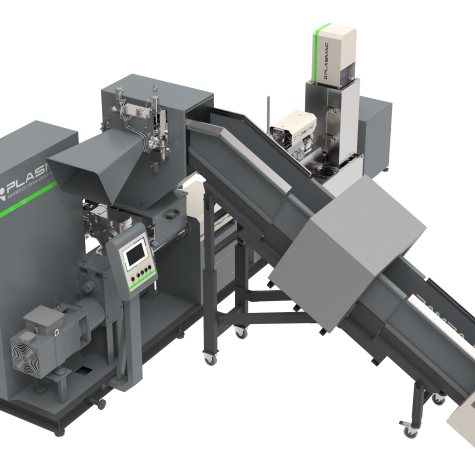

- TRIM BASKET for feeding inline trims into the recycling extruder.

- AIR or WATER COOLED PELLETISER: air or water pelletisers, the materials or output being run will determine the type of pelletiser required

- ROLLFEED Used to feed off-specification reels or scrap reels into the extruder, can be used simultaneously with the trim basket

- ELEVATOR Used to convey loose, slabbed, pieces and small lumps into the shredder

- SCREEN CHANGERS Manual or automatic systems available, used when running offline products i.e. reels, flake etc

- VACUUM DEGASSING STATION Single or double venting systems available to allow you to run printed or hydroscopic materials.

- DTEC A pellet detection system to advise if there are issues in the pelletiser.

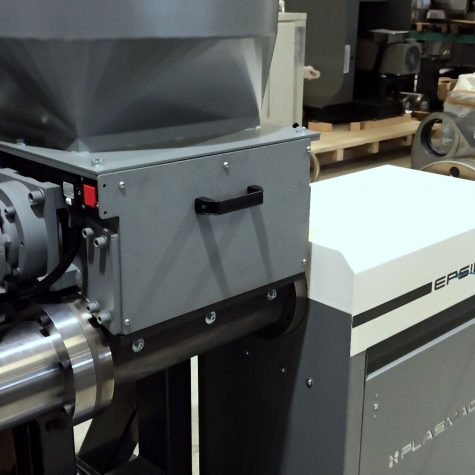

Epsilon

The most efficient recycling extruder available in the market

The EPSILON recycling inline shredder extruder system uses Plasmac’s unique Short Screw Technology (S.S.T.).

The waste material is fed via trim basket, rollfeed or elevator, in to the inline shredder, the size reduced material is then fed directly in to the feed throat of the extruder. No water cooling or compressed air is needed and the slow rotating shredder rotor ensures dust generation is kept to a minimum which means a higher quality pellet is produced with the lowest levels of gels possible. The S.S.T. ensures low shear, runs at low melt temperatures and therefore guarantees an absolute minimum of material degradation giving you the highest quality recycled pellet.