- ALL-IN-ONE SOLUTION Syntrol is designed to manage and support all Syncro machines, giving you complete control over the entire extrusion process.

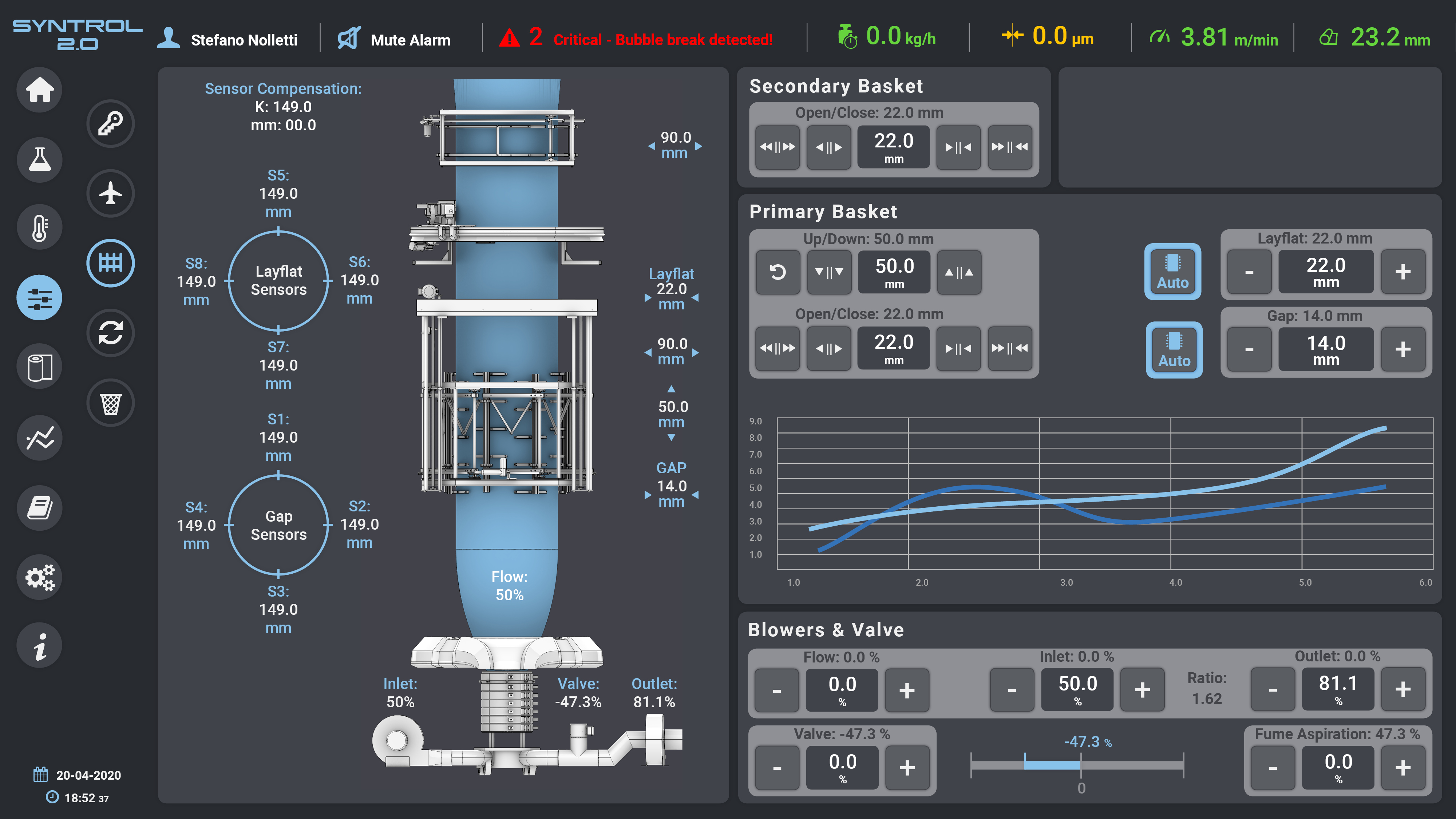

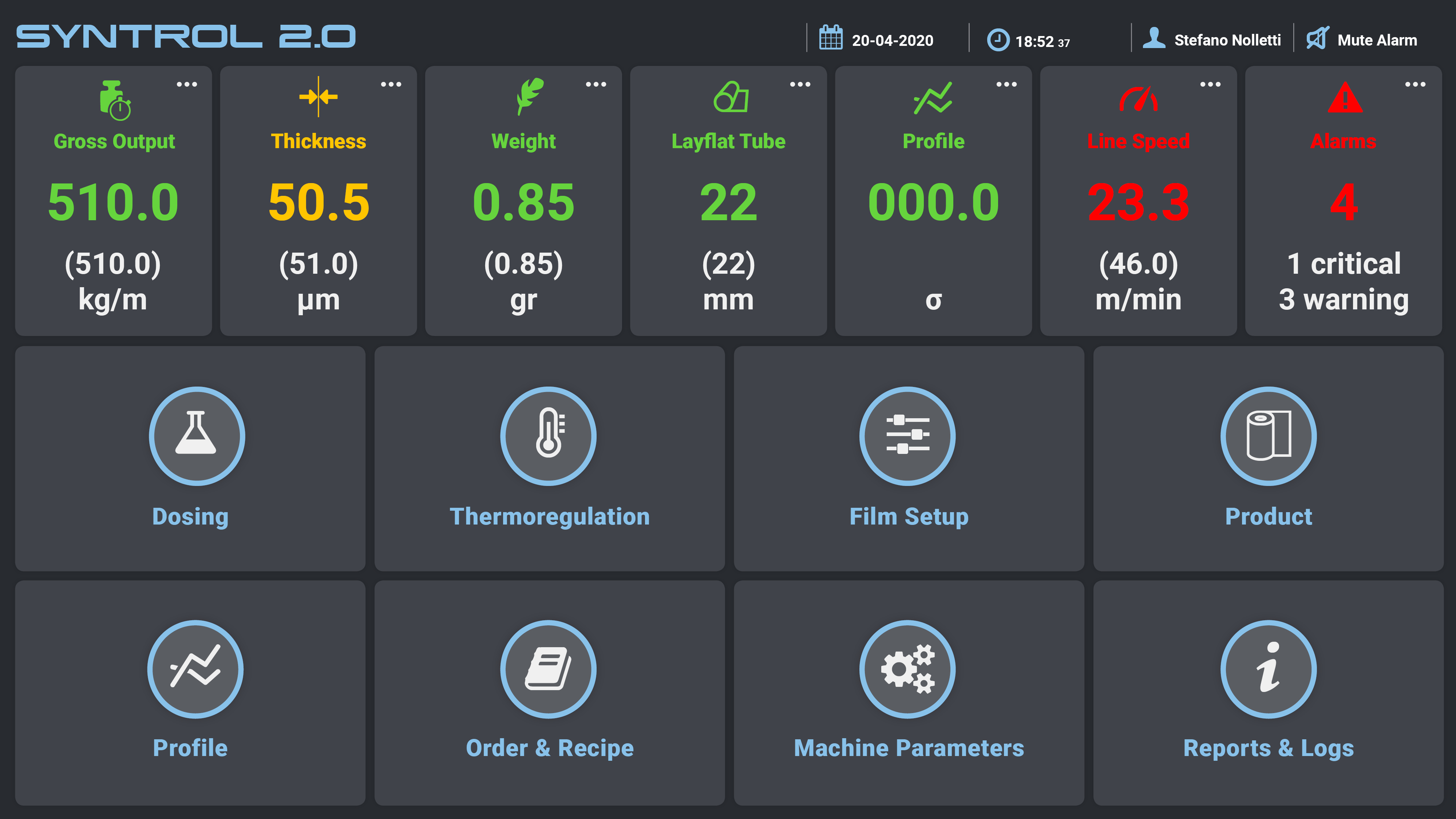

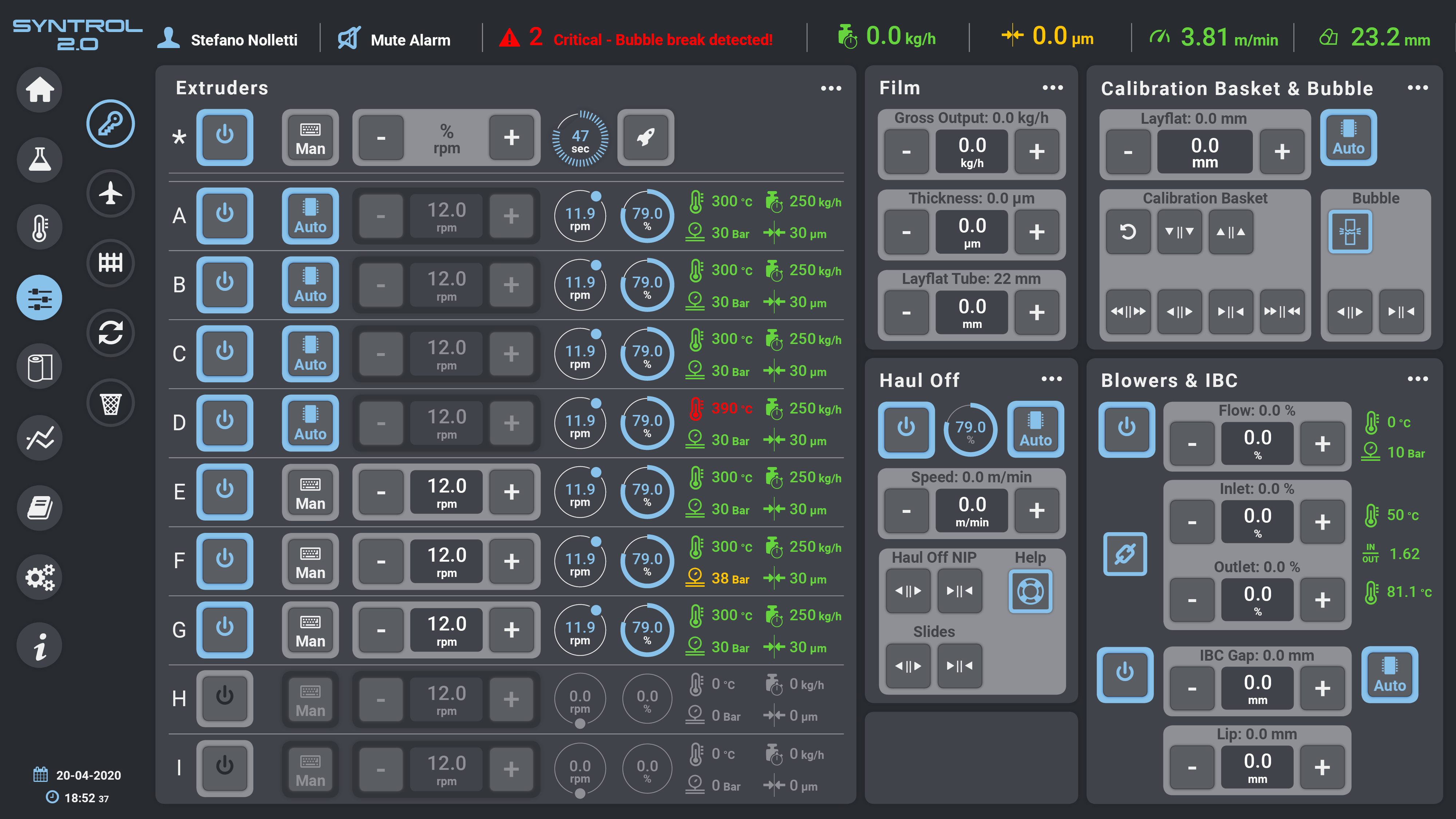

- INTUITIVE INTERFACE The interface has been professionally designed following the latest trends in information organization and user interfaces. It provides you with pages that are informative, responsive, easy to use and captivating.

- MODERN FUNCTIONALITIES Syntrol features function designed to optimize startup, production and maintenance, elevating your line from good to excellent.

- DATA COLLECTION The Syntrol Infinity database system enables safe storage and recall of dosing recipes, orders, production data, alarms and events. Our trends and production reports allow you to analyze and document in depth the state of your production, both current and past. Syntrol Infinity helps you plan, improve and reduce waste.

- ADAPTABLE SYSTEM Our PLC system is modular and compact, allowing easy adaptation to existing electrical cabinets and different hardware configurations. This makes your technicians’ work easier and enables fast and effortless transition to a modern and efficient way to control. Our system is 100% turnkey and designed to adapt to existing connections, with fully configurable IOs and analogic signals (0-10V, 4-20mA, 0-20mA).

- INDUSTRY 5.0 & IoT All Syncro machines are ready to be integrated with third party supervisory controls and ERP systems using the latest generation of OPC-UA protocols as standard.

Syntrol

Supervisory System 4.0 For Extrusion Lines

Syntrol system comprises: SYNTROL INFINITY, a modern and user-friendly touch HMI designed to provide the operator with fast and complete control of the extrusion line. Furthermore, extensive and in-depth data storage for production analysis allows you to keep your business always under control. SYNTROL PLUS, a state-of-the-art industrial PLC technology created to manage drivers and power of both Blown and Cast coextrusion lines. Our versatile and adaptable system will allow you to upgrade your production and control with minimal effort.