For an important Italian OEM, SYNCRO GROUP supplied auxiliary machinery for the extrusion line of a leading manufacturer of high-quality personal care and food products located in Surabaya, Indonesia.

A centre of industrial excellence, the company is constantly innovating and with SYNCRO GROUP has recently implemented an advanced technology for the production of packaging for oil bottles, finding the ideal partner to meet all its production and quality requirements.

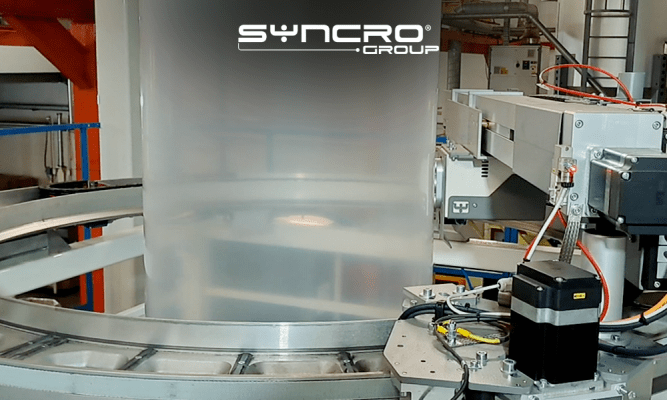

The company has recently installed a three-layer blown film extrusion plant, improving the film production process and enabling the production of shrink film for oil bottle packaging, as well as refill pouches, with high efficiency, precision and quality.

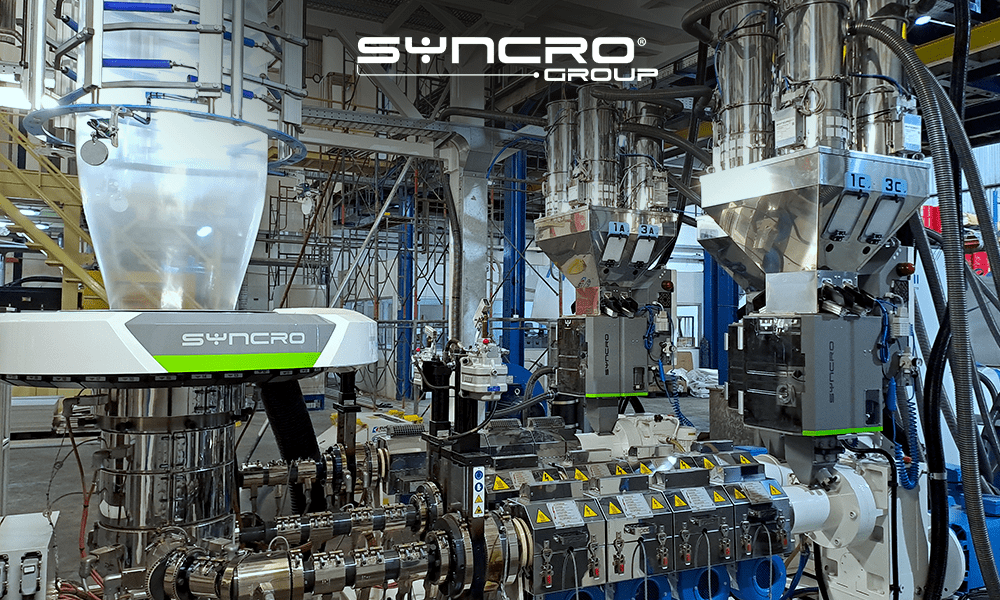

Key components of Syncro supply include:

- A system consisting of 3 Easybatch S4 units, which ensure an accurate dosing of ingredients during the production process.

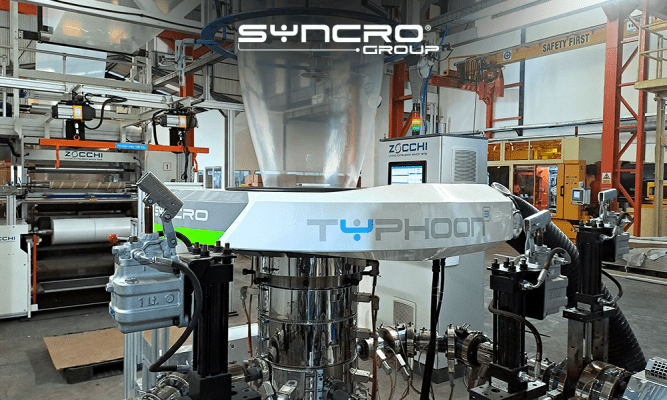

- A Typhoon3 Y1 single-boiler cooling ring with automatic thickness adjustment, equipped with 36 motors and an insert suitable for the 180 mm extrusion die, ensuring precise and uniform thickness control and bubble stability.

- Skymex with capacitive no-contact sensor for precise measurement and efficient production management.

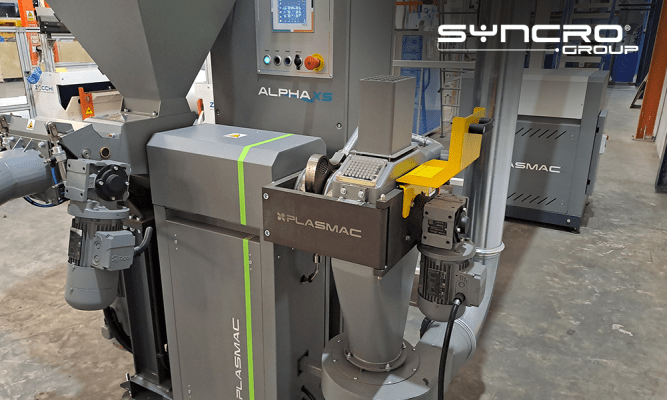

Recycling Production Waste with PLASMAC

The Indonesian company is very aware of the environment and the costs of production waste and has therefore integrated a PLASMAC Alpha XS regranulation line, supplied by PLASMAC, a leading manufacturer of plastic industrial waste granulating machines and part of SYNCRO GROUP and Erema Group. This line enables the direct recovery of production waste and scrap reels up to a maximum of 40kg/h and with minimal energy consumption, thus helping to reduce waste and improve the company’s overall profitability.

The images captured during production show the plant’s ability to generate 180kg/h of 60-micron thick shrink film, with thickness dispersion contained within only ± 1.1 microns at 2σ. The resulting reels, each 510 mm wide, testify the total recovery of production waste, underlining the effectiveness and efficiency of the newly implemented process with SYNCRO GROUP.

The investment in this state-of-the-art technology highlights the Indonesian leading company’s continuous commitment to offering high quality products in an efficient and sustainable manner. This advancement not only strengthens the company’s competitive position in the global market, but also demonstrates its commitment to environmental sustainability and industrial excellence.

SYNCRO GROUP is a leading supplier of automation for extrusion, quality control systems, material handling and storage, defect measurement, recycling lines, laboratory and pilot lines through the expertise of the companies SYNCRO, PLASMAC, PLANTECH-CST, ACELABS, EUR.EX.MA. and SB DRY.

The SYNCRO GROUP has 9 production plants as well as subsidiaries in the USA, Brazil, China, Japan and India.