Syncro Group is moving towards PLAST, one of the most important trade fairs for the plastics industry that will be held at Fiera Milano from 5th to 8th September.

For Syncro Group, Plast 2023 will be the opportunity to present the latest PLANET APPROVED products that have been always conceived in view of the ZERO WASTE MYSSION: reducing industrial waste, energy and raw material resources, while having a control on the total output.

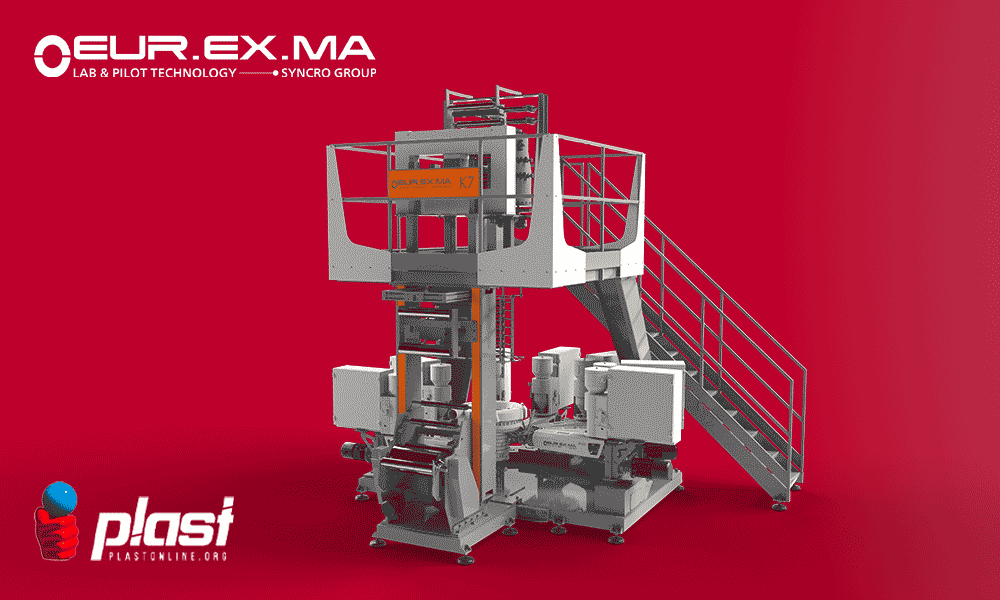

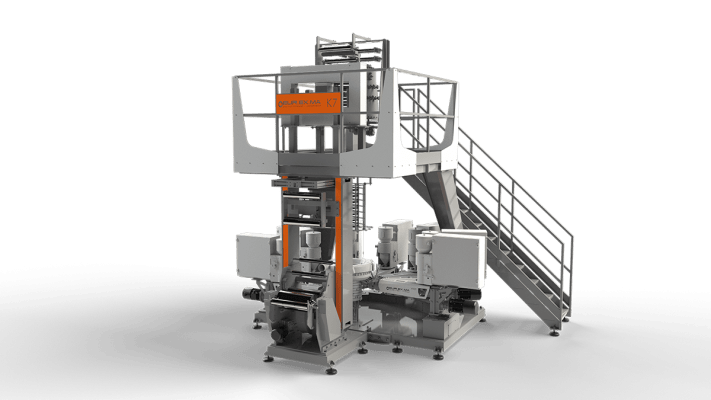

EUREXMA will take the field with the new PILOT BLOWN K7, the result of the close cooperation between two of the companies belonging to the Group, SYNCRO and EUREXMA.

Specialized in the production of Laboratory and Pilot lines, EUREXMA is one of the latest companies to join Syncro Group and can supply extrusion lines for various processes and products, most notably the tubular film, both mono and multi-layer.

EUREXMA‘s laboratory and pilot extrusion lines, in fact, represent an advantageous and effective solution for all companies and research institutes that plan to develop multi-layer film formulations with different features and sizes, with reduced costs and consumption.

Among these lines we can find the PILOT BLOWN K7, a pilot line for the production of 7-layer films, which is useful for developing multi-layer film formulations with polymers with different properties:

- Barrier towards oxygen, carbon dioxide and odors

- Lightness

- Mechanical strength

- Heat and UV resistance

This makes it possible to obtain structures with great functional properties, able to meet the increasingly stringent standards imposed in the food and medical industries.

The PILOT BLOWN K7 consists of 7 XTR 20 extruders with 20 mm ø screws, suitable for processing different types of polymers with different features and viscousness.

The tubular film come out of the 80 mm ø die is cooled thanks to the innovative cooling air ring produced by SYNCRO, as well as the smallest automatic ring available on the market today, the TYPHOON Y00. This air ring, thanks to the presence of 36 thermoregulation zones, can guarantee a homogeneous temperature over the entire surface of the tubular film, ensuring the best performance in terms of cooling capacity, bubble stability and accurate profile control.

Furthermore, thanks to the combined action with SONYSCAN, an innovative ultrasonic scanner provided by SYNCRO, it can guarantee a precise film thickness control with excellent tolerances.

The combined action of all these elements makes it possible to obtain a tubular film of different widths, up to a maximum of 400 mm and different thicknesses, with a range from 20 to 150 microns.

The produced film is then analysed with EYES, a visual quality inspection system produced by ACELABS. This system, thanks to its high-resolution cameras and different lighting configurations, can scan 100% of the film, detecting and classifying every type of defect.

Finally, the presence of SYLINE XXS gravimetric feeders, placed on all the extruders of the line, ensures a precise control of the extruder output.

SYLINE XXS, in fact, thanks to the action of an off-center load cell, is designed to gravimetrically feed the extruder mouth and control its output.

Syncro Group makes it possible to find in one GROUP all the advantages and experience from different specialists in the field, thanks to the synergy created between the companies SYNCRO, PLASMAC, PLANTECH-CST, ACELABS, EUR.EX.MA. and SBDRY.

CLICK HERE TO GET YOUR FREE TICKET