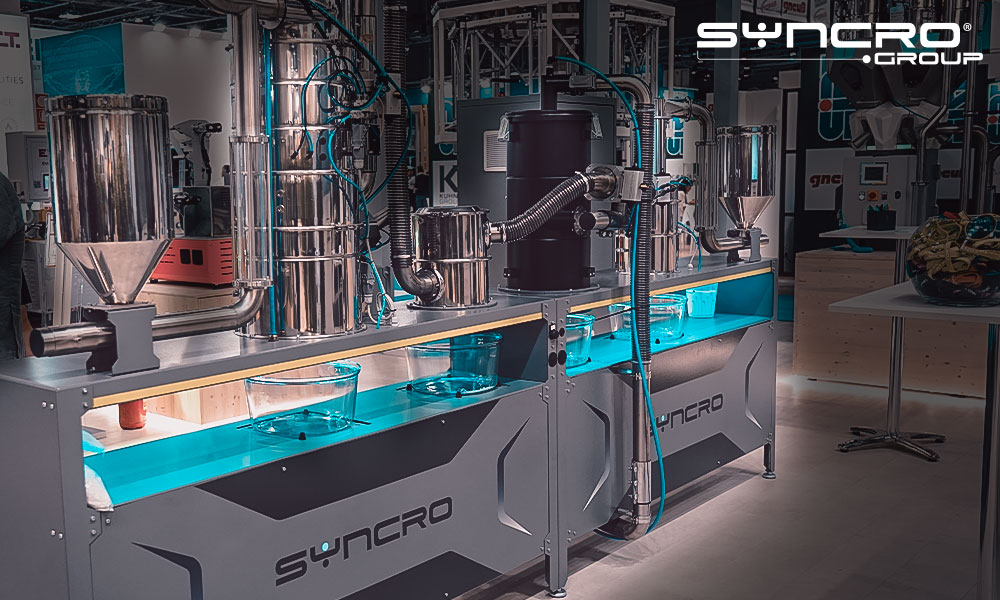

Today we will talk about the advanced solutions patented by Syncro, starting with Dyduster. The Dyduster is a hopper loader equipped with an integrated de-dusting unit. Its main function is to continuously extract the powder from your plastic granules, ensuring a smooth production process. Imagine that you have your raw material, granules and a ready amount of powder.

Now, let’s start the cycle. In combination with the Dyduster, Syncro has developed a revolutionary solution to face the “Angel Hair Trap” problem, which often affects the plastic manufacturing industry.

The Angel Hair Trap is a phenomenon in which thin plastic filaments (angel hair) stick to the equipment and interrupt the production process. To tackle this problem, Syncro has designed a unique sector inside the Dyduster. This sector captures and retains all angel hair, then removes and eliminates it efficiently. To illustrate its operation, we take some plastic angel hair and combine it with raw material and granules. Once the cycle starts, you will see the granules being conveyed, with the angel hair integrated into the mix flawlessly. The mixed material then descends through the system.

Thanks to Syncro innovative solution, Angel hair is cleverly trapped and then released on a different filter. This process ensures that your production remains smooth and efficient, free from interruptions caused by angel hair.

In brief, Syncro advanced patented solutions, including the Dyduster and its Angel Hair Trap solution, provide a powerful boost to efficiency in plastic manufacturing. By effectively managing dust extraction and preventing angel hair-related disruptions, Syncro is contributing to the improvement of the plastic manufacturing industry.

Stay tuned for more updates and innovations from Syncro, while we continue to push the limits of what is possible in plastic manufacturing.