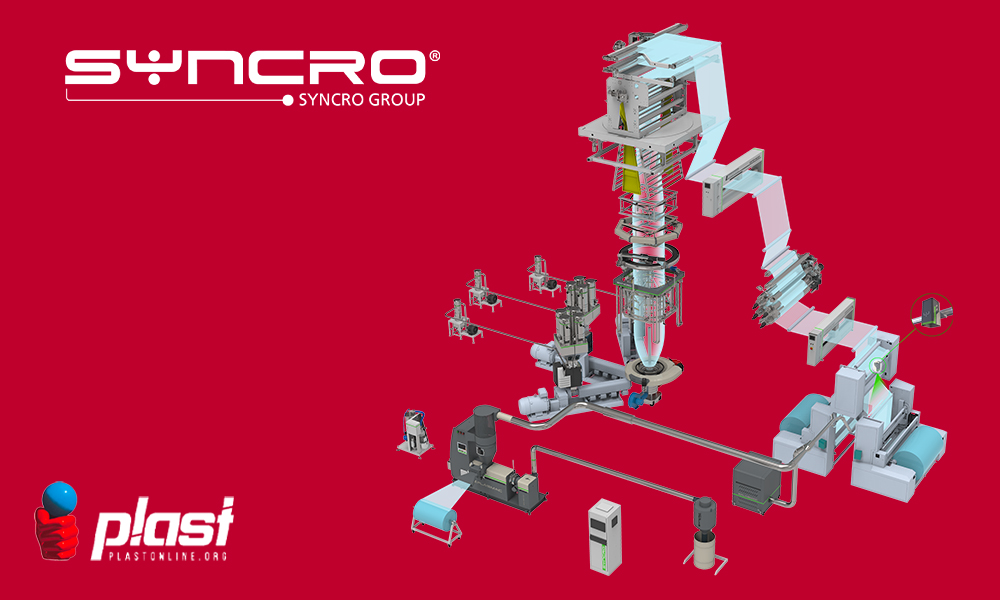

Syncro Group is moving towards PLAST, one of the most important trade fairs for the plastics industry that will be held at Fiera Milano from 5th to 8th September.

For Syncro Group, Plast 2023 will be the opportunity to present the latest PLANET APPROVED products that have been always conceived in view of the ZERO WASTE MYSSION: reducing industrial waste, energy and raw material resources, while having a control on the total output.

Come and find out, on the 500 square meters island completely dedicated to the Group, an ever-changing range of products exhibited by SYNCRO, which has been a reference point in the field since 2007:

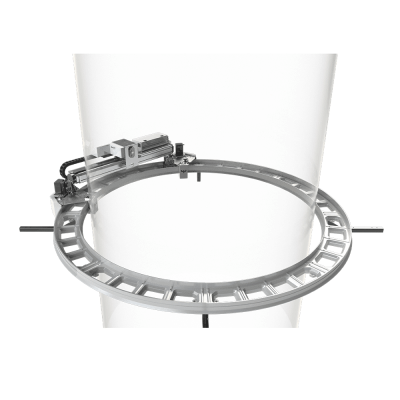

TYPHOON³, the special design of the feeding chamber and its turbulator (patented by SYNCRO), optimizes air distribution along 360 degrees of the ring circumference and a planar and homogeneous filling of the radial control channels. TYPHOON³ is an evolutionary and energy-efficient automatic cooling air ring. The automatic cooling air ring, which can accommodate single lips, dual lips or flyer inserts, is an evolutionary step up from its predecessor in terms of cooling capacity and bubble stability (increased output per hour), increased energy efficiency (lower consumption), faster correction of the profile thickness dispersion (less waste during start-up and recipe change) combined with a more efficient and precise thickness control.

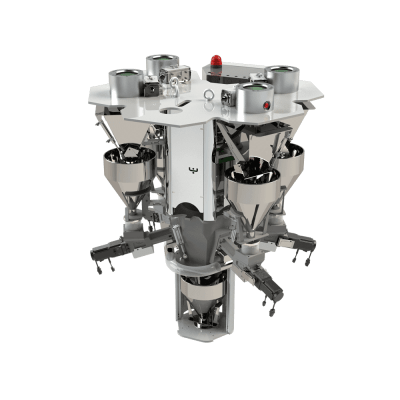

MYBATCH³, in world preview there will be the new batch feeder, completely redesigned with a compact and attractive design. MYBATCH³ is characterized by better performance in terms of dosing precision of minor components and homogeneous mixing. The feeder is configurable from 2 to 6 components. The possibility to process hot materials, to dose granulated or ground materials, to automatically drain one or more components, to assemble individual hoppers and their hopper loaders directly on the machine or, alternatively, to connect the feeder with pipes to pre-storage hoppers and hopper loaders housed on the mezzanine are some of the options available.

SYBLEND, the gravimetric continuous loss-in-weight dosing unit is designed to dose and blend several components simultaneously. The precision and responsiveness of the motor-driven screw feeders guarantee from the very first moments of operation and at every small variation in granule transport, a correct components ratio, a homogeneous blending and a control of the extruder output, which are essential to achieve the correct layering and quality of the end product. It is the ideal feeder for all multi-layer extrusion processes and in the yarn industry such as BCF, FDY and POY processes.

MYBLEND, the addition of a batch-weighed hopper interposed between the feeder and the SYBLEND loss-in-weight dosing unit creates a dosing unit capable of recognizing and correcting possible problems during the loss-in-weight hopper refilling phase, a phase of unavoidably volumetric operation in all machines operating with loss-in-weight. The presence of two simultaneous gravimetric systems, one of batch type and the other of continuous type, makes it possible to certify the actual quality of the dosing performed by the dosing unit and to indicate anomalies or the need to calibrate the load cells active in the two systems too. For this reason, MYBLEND is the ideal feeder for all processes where the dosing control and stability must be contained within very tight boundaries, as in the case of textile and pharmaceutical lines.

TETRYX, the automatic material sorting control unit allows up to 24 pick-up points (silos, day-bins) to be connected to a maximum of 24 hopper loaders in one single station, fully automating the transport of materials from storage to users. The number of inputs and outputs, determined by the system configuration, can be extended with total freedom by arranging several stations in sequentially.

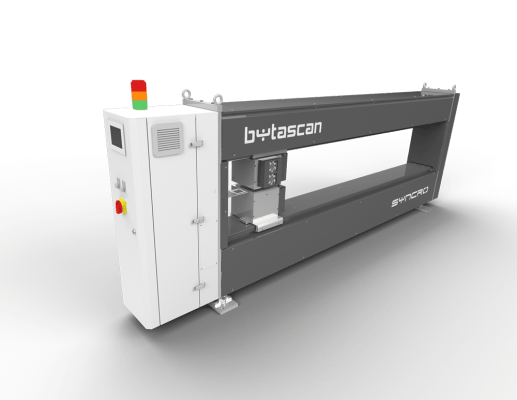

SKYMEX, the oscillating or rotating around the extruded bubble thickness gauge can be capacitive of contact type, capacitive of non-contact type or X-ray backscatter. The sensor installed on the central element of a three-stage telescopic beam (patented by SYNCRO) is always aligned with the bubble axis in middle position between the two motorized trolleys on which it is pivoted at its ends. The main advantages of the machine are the reduced rotating dimensions, which are essential for the installation on small spaces of the customer’s frames, the rigidity of the telescopic beam, the absence of vibrations and the extended working range up to a 4:1 ratio between maximum and minimum bubble diameters.

DYDUSTER & EASYTRAP, SYNCRO feeders develop new features, such as separation and powder removal from the granule feeding the dosing unit and the extruder, by eliminating at source the occurrence of film surface defects, gels and infusions of angel hair and several unwanted and costly downtime due to misfeeding, thus limiting production defects and, even more, waste and out-of- tolerance products.

ZYROWAX, the suction of monomers and particles released into the environment by the extruded bubble at high temperature improves the air quality of the factory environment and extends the operating time of the plant by reducing the number of cleaning operations of the cooling ring inserts and other parts of the plant on which they deposit and accumulate.

ZYROBLOCK, by exploiting the mechanics of the bubble guides that accommodate the variable bubble diameter, it is possible to insert additional cooling air blowers either as additional levels of the main bubble guide or as actual bubble guides positioned before the collapsing floors and the nip, reducing the bubble temperature when the increase in hourly production and the temperature of the environment are particularly critical due to the well-known blocking phenomenon.

SKYLAB, a laboratory machine for measuring the film thickness taken from the just finished reel is now available on the line. The thickness profile taken from the film strip of the finished reel and that taken on the bubble in production are processed, compared and correlated by the same processor. Measurements previously disjointed and now associated can provide in almost no time indications, checks, verifications and automatic defect identification and correction procedures to guarantee the quality of the finished product.

THICKNESS GAUGES, the range of thickness gauges available in SYNCRO can meet the specific requirements of extrusion and pairing processes.

Layerscan: it can simultaneously discriminate and measure both total film thickness and barrier layer thickness in a multilayer structure

Optyscan: it is an optical sensor measurement system

Rayxscan: it uses X-ray transmission to measure material uniformity

Combyscan: it is a non-contact measuring system based on combined inductive and capacitive technology

Shadyscan: it is a laser projection & inductive eddy current sensor thickness gauge

Bytascan: it uses the principle of Beta-ray transmission through the material to measure its density, weight and thickness usually indicated in g/m2 or μm

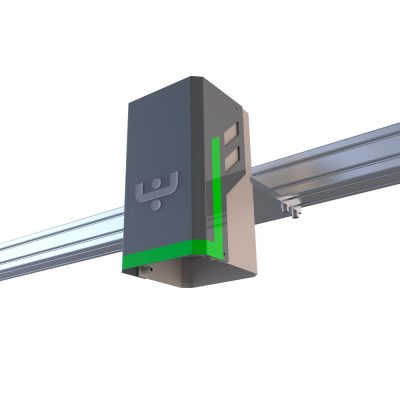

MODYX, the new continuous loss-in-weight feeder is designed to ensure the precise gravimetric feeding of a component into the extruder’s mouth which, in relation to the other recipe components, respects the total extruder output.

On the island of Syncro Group you will find a section entirely dedicated to the complete range of WIRE&CABLE gauges; systems to control the main process parameters in the electrical cable extrusion are the following ones:

DIAMEX series gauges, dedicated to non-contact diameter measurement of cables and pipes of various sizes

DEFEX, a state-of-the-art optoelectronic device for the on-line measurement and identification of surface defects, such as protuberances, constrictions, abrasions, local absences of insulation, partial detachments or flakes

VELOMEX, a laser gauge for determining length position and linear speed

GLIMEX, a Spark tester for checking the integrity of cable insulation which allows on-line detection of insulation defects in an electric cable, such as holes, cuts, flaws or absence of insulation

The strength of Syncro Group can be seen in the synergy created among all its companies, of which our EYES is another example. The unique synergy between SYNCRO and ACELABS has given birth to a vision system for in-line quality control of plastic films, thus guaranteeing a complete solution package for quality control, in line with the highest standards of automation.

Syncro Group makes it possible to find in one GROUP all the advantages and experience from different specialists in the field, thanks to the synergy created between the companies SYNCRO, PLASMAC, PLANTECH-CST, ACELABS, EUR.EX.MA. and SBDRY.

CLICK HERE TO GET YOUR FREE TICKET